Gemba

Gemba (現場) is the Japanese term for “actual place,” often used for the shop floor or any place where value-creating work actually occurs. It is also spelled genba. Lean Thinkers use it to mean the place where value is created. Japanese companies often supplement gemba with the related term “genchi gembutsu” — essentially “go and see” — to stress the importance of empiricism.

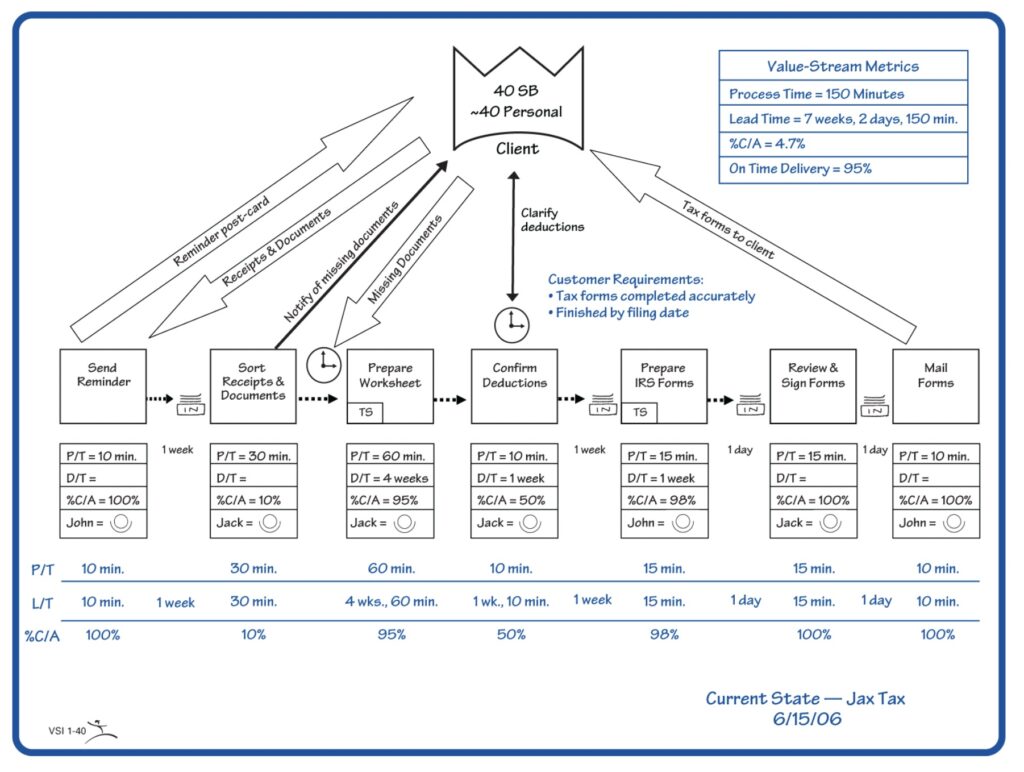

A gemba walk is a management practice for grasping the current situation through direct observation and inquiry before taking action.

The gemba is different depending on the industry.

| Industry | Example Gemba |

|---|---|

| Manufacturing | Factory floor |

| Hospital | Operating room |

| Hospitality | Kitchen, dining room |

| Construction | Job site |

| Software | Software code |

The term often is used to stress that real improvement requires a shop-floor focus based on direct observation of current conditions where work is done. For example, standardized work for a machine operator cannot be written at a desk in the engineering office, but must be defined and revised on the gemba.

It is essential for leaders to spend time at the gemba for two primary purposes:

- To raise consciousness about the possibilities for dramatic end-to-end improvement.

- To assess the ability of the management system to maintain stability, which is also the basis for successful improvement.

By walking the end-to-end value-stream leaders can identify opportunities to eliminate steps in a production or service process. The result can dramatically lead time from order to delivery, as well as simplify operations leading to higher quality and lower cost.

Because value flows horizontally across companies to customers, a productive way to take a gemba walk is to follow a single product family or product design or customer-facing process from start to finish across departments, functions, and organizations.

Additional Resources