In product development, a lot of people are working on the same data at the same time. And there are a lot of trade-offs in interfaces in the design work. When we don’t have those things synchronized, a lot of times, we are working with unstable data. We start doing work and then have to rework it as we go through. And that causes more time on the project. But frankly, it also causes more frustration for the team members. No one likes to do work and have to rework it again.

… product development value-stream mapping has been a valuable technique to help teams see how they do their work and how it fits together. And as they see that, they also see opportunities to improve their work …

So product development value-stream mapping has been a valuable technique to help teams see how they do their work and how it fits together. And as they see that, they also see opportunities to improve their work. It [VSM] was originally described by John Shook and Mike Rother in their book Learning to See many years ago, and the goal, whether you’re designing a product, a service, or a process, you’re trying to create new value for your customers.

In that regard, the product development value-stream map helps us visualize where that value is being created and where we are being blocked from creating that value as a team and in our individual work.

So, the main components of product development value-stream mapping, starting with the current state: Where are we today? What’s going on? And where are the challenges? And the future state: Where do we want to be in the future by eliminating some of those wastes and pain points? And then, to get there, the most important part is creating an action plan to move from that current state to the future state.

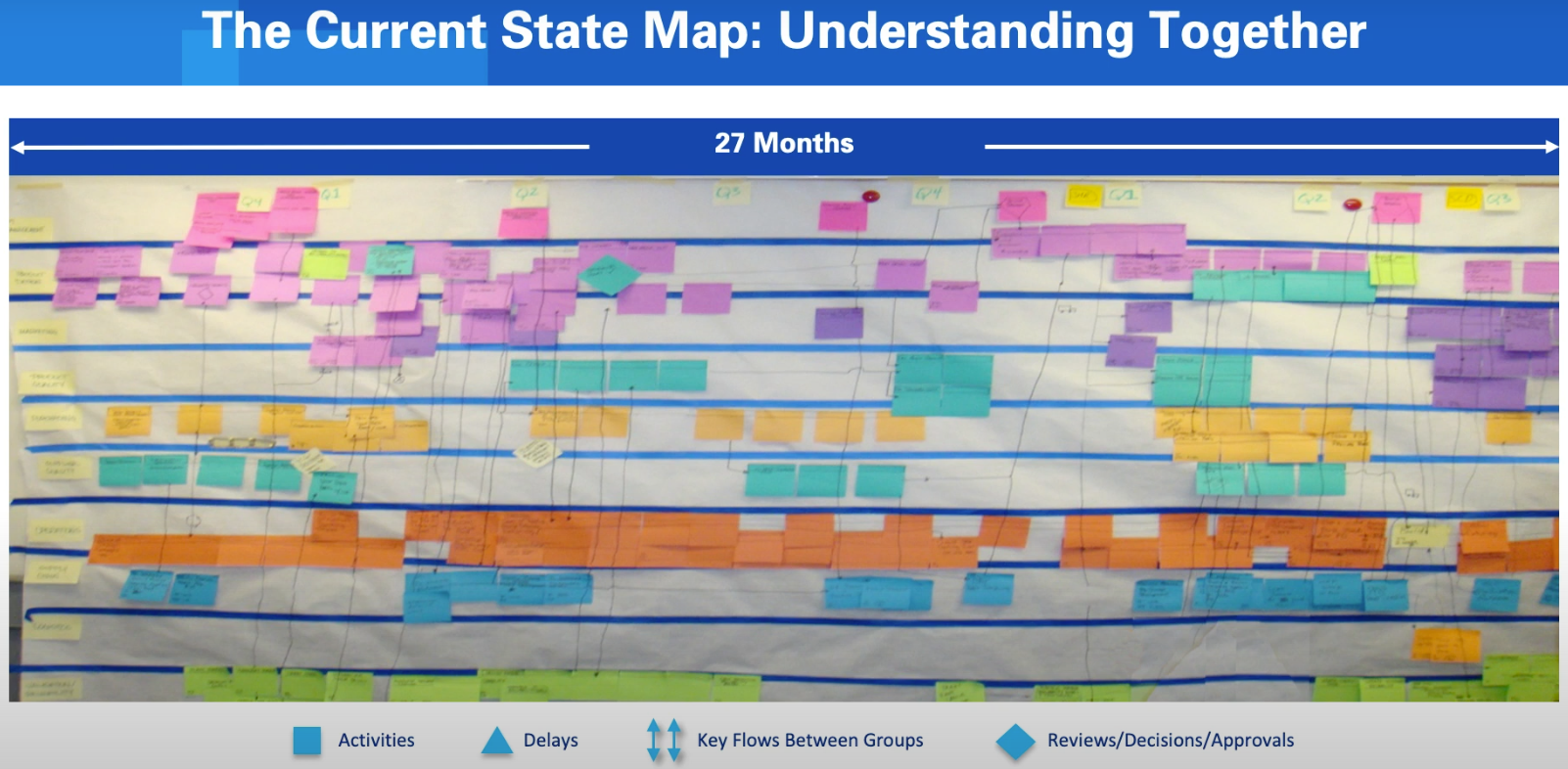

The Current-State Map

The current-state map is the starting point of the product development value-stream mapping process. Before it’s possible to make any improvements, we all need a common understanding of how we’re doing the work today. Then, as we start seeing how the work is being done, and we’re sharing and comparing, we start seeing how it all fits together. And as we start seeing it coming together, we start understanding where the value is created.

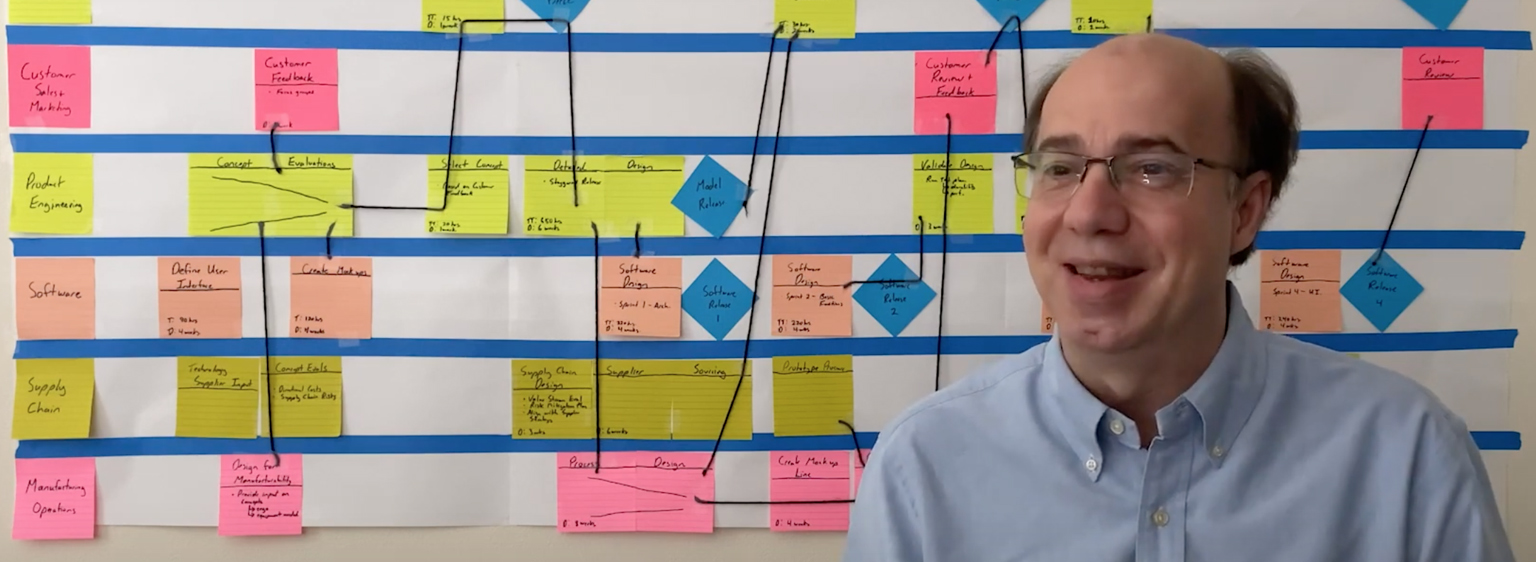

As we always say, product development is a team sport. So, you will see multiple swim lanes on your value stream maps. Everybody needs to have a place to show their work. Each line represents a different person or group and how they contribute value to the particular product or service that is being delivered and designed.

As we look along the top, teams run to a timeline — because we need to understand what the team is doing, what kind of work they’re doing, and when it’s happening.

Time is a crucial element: We need to understand where that work is behind schedule. And usually, you need a pretty big piece of paper or a big wall because there’s a much larger timescale. By comparison, in manufacturing, we use a stopwatch; in product development, we use a calendar for measurements. So the timescale and the number of actors are dramatically different.

On the map, the squares indicate processes. There are delay points as well, which are usually represented by triangles. And, of course, we have connections between the different groups.

In the product development value-stream maps, you will see a lot of interdependencies. And highlighting those interdependencies will help synchronize that work or see where it’s not synchronized.

And the last shapes you will see are diamonds, which indicate when the development team must come together, share their knowledge, integrate their work, and make decisions. And these integration events are critical to product development because this is when we see where that value is coming together.

The map you see here (above) is from a company that designs and manufactures high-precision equipment. In their current state, they were taking 27 months to bring a product to market. The project team designing their next-generation product had the challenge of significantly reducing that time to meet their customers’ needs and stay ahead of the competition. By visualizing their current state, the team was able to identify areas where they could improve the process and accelerate the time to market.

Seeing the ‘Pain Points’

When you put together a current state map, another thing that happens is you start seeing the pain points. Here are some pain points, or wastes, typically found when mapping the current state that stop teams from creating value. As we map, we also start understanding where those pain points are hiding, how big they are, and, most importantly, how they impact not just one person but the overall team.

Product development is not a one-person show. In many ways, the entire enterprise is interconnected to create that future value stream for the customer. So, we must have those different perspectives to understand the current state. And as we start getting those groups together, we also start getting, I think, a little more empathy on what each other needs. That empathy then allows us to work together to try and find solutions and help each other work more effectively.

The Future-State Map

The future state is a vision of where we want to go with our product development system and is designed to bring out people’s talent and help them create value in the most effective way possible. Coming back to the earlier example, the project team created their future state by incorporating some of the lean product and process development practices to address the pain points they identified in their current state. As a result, they were able to shorten their development time from 27 months to 15 months.

The future-state map is going to be different for each organization. Each organization has distinct value creation, different customers, and unique challenges. So, when we talk about what a good future state looks like, that’s determined by the development team. However, in lean product and process development, we have a few guiding principles to help you as you start your journey. The concepts at a very high level and principles are fairly straightforward, but putting them into practice sometimes is very challenging.

By going through the future state, we create a scenario where people see that vision of how they apply those principles to attack the challenges and waste they have in their process — and, quite frankly, make it real. Some challenges are going to arise. Some surprises are going to happen. And you want to make sure that you pivot to adjust to those situations while staying true to your course. And that future state is a great anchoring point.

The Implementation Plan

As you’re creating your future state, it doesn’t answer all the questions. It gives you a direction. The implementation is where you test it out. We need to change the process toward the future state. There will be challenges along the road. You will need to do several learning cycles and run experiments. The future state, in many ways, is a hypothesis; it should be based on some reality and buy-in from the team. But it should be aggressive enough so that we challenge ourselves on how we can improve to deliver that value to our customers.

The other thing is the future state is not a one-and-done. So, as you start moving forward, you will probably see some opportunities to go to a future future state, and that’s okay too. But as a team, you must have a good implementation plan that lines up and applies to the project that you’re working on.

… we’re designing the future product or service, and we’re improving the way we do that process at the same time. So, in many ways, you’re improving the railroad as the train goes down the track.

That’s one of the things that’s a little unique in terms of implementation for us in product development, we’re designing the future product or service, and we’re improving the way we do that process at the same time. So, in many ways, you’re improving the railroad as the train goes down the track. And that’s part of the improvement process, but it’s imperative to have a good game plan because after you’ve created your future state, everybody’s going back to work. So, we need to ensure we’ve got actions to improve built into our project plans.

Product development value-stream mapping is a universal technique. It can apply to almost any industry, whether a product, a service, hardware, or software. I’ve seen it applied to everything from very simple processes, like developing a squeegee, to very complex, like an aircraft carrier, and anything in between.

My sincerest hope is that you can use this methodology to get your teams talking to each other, see how their work fits into the big picture, and achieve a mutual understanding of how it fits together. And then see where we can help each other to eliminate those pain points or waste that get our way every day. So that, ultimately, we can free up our people’s time to work on those important elements of creating value and addressing the challenges we have within our organizations and society at large.

Editor’s Note: This Lean Post is an updated version of an article published on November 20, 2020, one of the most popular posts about this vital lean practice.

Learning to See Using

Value-Stream Mapping

Develop a blueprint of improvements that will achieve your organization’s strategic objectives.

This article was very impressive on the importance of lean manufacturing. The value stream map has opened up my thinking on how a process can be simplified. The idea of having to redo work that is poorly completed is a painful one. Why spend time reworking when non valuable time can be eliminated through mapping.

Excellent and knowledgeable articles , would like to receive all such articles regarding Lean Manufacturing .