Lean management practitioners know what a powerful tool standardization is for continuously improving processes. Without standards, there can be no improvement as the old saying goes. Yet as LEI faculty member and author Art Smalley points out this does not only mean one rigid way of doing things such as standardizing your problem-solving approach on only a single methodology like six sigma or 8D or a specific technique like 5 Why

To that, author and long-time lean practitioner Art Smalley answers “Ok, then why not only use TRIZ? Why not only use PDCA? Why not use only Design Thinking? Why not only do FMEA? Why not only use kata? Or similarly why not only use only one style of leadership? Why not play golf with only a 7 iron?” The reality is that life and problem solving have various shades of gray and what may work great in certain situations may not work as well in others. Over the last century, a plethora of problem-solving tools and techniques have been developed because of this situational reality.

When attacking business problems, one approach won’t work optimally in all situations, explains Smalley, who learned problem solving at Toyota’s Kamigo engine plant from Tomoo Harada, who led various maintenance activities that created stability for Toyota Production System architect Taiichi Ohno’s innovations in flow production. For a comparative example, in Toyota we talk about three types of pull systems (replenishment, sequential, and mixed). There are also three types of standardized work and four types of automation levels when planning for equipment. The devil is in the details as the saying goes. The more advanced you get in a given subject area the more you are expected to learn the nuances and differences according to the situation.

By way of comparison, there are similarities in other fields. Nobel Prize winning author and researcher Daniel Kahneman emphasizes the important difference in what he and Amos Tversky called System 1 and System 2 thinking patterns. Creative thinking expert Edward de Bono believed in six different hats or types of thought process in his books on creativity for example. Each style applied best to different problem-solving situations. Paul Hersey and Ken Blanchard emphasized four types of leadership styles in their Situational Model for Leadership.

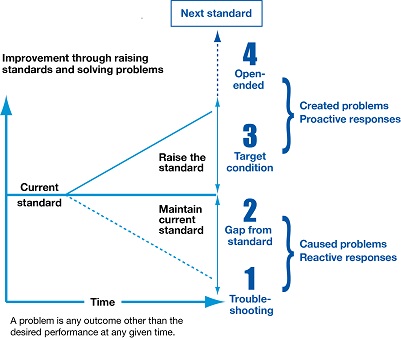

Problem solving, Smalley points out, is very similar in this regard and has patterns in its development cycle. The first divergence is in the caused versus created distinction. Some problems in the former category require a quick reaction approach to “stop the bleeding” or “protect the customer” while others require a slower, analytical methodology to determine deeper problems and root causes. Still, other problems require higher levels of creativity utilizing existing resources and others which allow for fuller open-ended exploration in order to produce breakthrough results.

5 Whys, 6 Sigma, and 8Ds

But managers and teams normally tend to settle on a favorite problem-solving technique or two from among all available — whether it’s brainstorming, fishbone diagraming, failure mode effects analysis, value-stream mapping, kaizen events, design of experiments, A3s, 5 whys, 6 sigma, or the 8Ds – that is often mismatched for the problem at hand. Yes one can force all problems into one approach cautions Smalley, it is just not optimal. Toyota, for example, has multiple nuances in its internal approach. A recently published book in Japanese by retired Toyota executives entitled Problem Solving the Toyota Way makes similar points. Managers need a framework for thinking carefully about problem-solving situations and what approach to select.

Based on his observation that most business problems tend to fall into four categories, Smalley provides the framework in his new book Four Types of Problems. He explained the framework during a recent LEI webinar that drew nearly 3,200 registrations then took questions from the audience. Listen to the webinar and Q&A here. What follows are Art’s answers to questions not addressed during the one-hour live session.

The Four 4 Types of Problems Webinar

Follow up Q&A with presenter Art Smalley, author of Four Types of Problems

Q: Is type one the same as firefighting?

Art: I don’t know what you might consider firefighting. You could be thinking of something really weak in the nature of the response. Then there are very good local fire fighters for example that respond to local emergencies with excellent response time and first responder techniques for life saving. And then there are expert “hot shot” style emergency wilderness firefighters who fly or drive into danger zones and execute special routines. We’d have to get the definition clear to avoid communication mistakes. In my case, type one troubleshooting is aimed at addressing both conditions and some basic level of causal analysis in a rapid fashion. Hence the 4C acronym I used — concern, cause, countermeasure, check results — within the framework in the section on that style. Sometimes putting out the fire is an unfortunate but necessary condition to first address. Then, of course importantly, what caused it — the 2nd C. Sometimes this is done sequentially, sometimes in parallel. In serious cases, you might move right into type two mode of handling the problem.

Q: For many people, when we use the phrase “problem-solving” their minds go to types one or two problems only. It is not natural for them to see types three and four as problem solving. Do you have any advice on how to effectively spread this mindset through an organization?

Art: I agree it is a big issue … that was part of the thinking with the framework and getting people to think beyond their usual normal narrower definition and think from a broader perspective. We have to think in terms of both caused and creative based routines and each has its own sub categories. I could argue for more but I think this represents a reasonable solution space and does justice to what Toyota does in reality.

Q: What about the coaching element in problem solving? That is, IMHO, a key part of capability building [in the] improvement kata and coaching kata.

Art: Entirely agree. Capability building (more than just coaching) is an entire element worthy of its own topic. It was just out of scope for the 45 minutes I had for this presentation. Just as there are different types of problem approaches in Toyota there are also different types of leadership and coaching styles. What Mike Rother refers to in his coaching kata that you referenced is one style, for example. There are more, at least at Toyota. This presentation grouped four types of problems under the first heading of the transformation model developed by the Lean Enterprise Institute (LEI). I could spend another webinar easily on the different actions to support capability build and the 4 types. That is another structural pillar of the LEI transformation model I’d like to elaborate on some day.

Q: Do you have any recommendations for how to effectively educate an organization on these principles given the bell curve of different types, personalities, and willingness to change and apply different approaches?

Art: I think everyone can do type one problem solving and that is the entry point to engage people. That was all I experienced for my first several months in Toyota and time on the assembly line. Then I graduated types two, three, and four.

To what extent each type can be mastered is difficult and probably links to cognitive abilities. However, I am no expert in this area and it can get controversial very quickly. Everyone deserves the chance to problem solve and impact their own work. I don’t believe we will achieve equality of results in terms of outcome. I freely admit I can’t hold a candle to my former boss on the topic of engineering, for example. He was one of those off-the-charts exceptional people even inside Toyota.

Q: Any suggestions for how problem solvers should maintain a beginner’s mind?

Art: I like to work on hard and different problems that are far outside of my skill set. If possible I put myself in the room with some real experts on a given subject matter like material science for example. Humility usually follows pretty quickly. Or they can come to my morning Jiu Jitsu class and try to roll with a black belt or two. That works wonders for me as well. LOL. Some people are more secure facing uncertainly or difficulty than others. I’d learn about the person in question and what I could do to take them safely out of their comfort zone.

The 4 Types of Problems Framework

- Troubleshooting: A reactive process of rapidly fixing abnormal conditions by returning things to immediately known standards. While beneficial in the immediate term, this approach often fails to solve the problem’s root cause. Example: When a house is on fire protect the occupants, treat injuries, and put out the fire. With a flat tire on the freeway,first put on the spare tire.

- Gap-from-standard: A structured problem-solving process aimed more at the root cause through problem definition, goal setting, analysis, countermeasure implementation, checks, standards, and follow-up activities. Example: Extinguish the fire, then determine what caused it and how to prevent another.

- Target-state: Continuous improvement (kaizen) that goes beyond existing levels of performance to achieve new and better standards or conditions. Example: Use superior layouts, building materials, and landscaping methods that are less likely to lead to fires in the first place. Creativity is utilized over capital to optimize performance to a new level.

- Open-ended and Innovation: Unrestricted pursuit through creativity and synthesis of a vision or ideal condition that entail radical improvements and unexpected products, processes, systems, or value for the customer beyond current levels. Example: Develop systems that detect, prevent, or immediately stop fires from occurring right away?

Q: What’s your approach to problem solving when certain members don’t want to listen or aren’t willing to change or give you a chance?

Art: Sorry I’d need to know more details. Often personality conflicts arise and make it difficult to produce change. This could be as much or more about leadership influence than problem solving.

Q: How can we make time for team leaders to do more problem solving ?

Art: I tell all my clients we can’t “make” any more time. We can simply choose to use our existing time more wisely and effectively. Easier said than done of course.

Q: How does this relate to Heifitz’s three levels of technical, technical-adaptive, and adaptive problems/challenges?

Art: I think he identifies two types of challenges in change: technical and adaptive (and an in-between step mix). Technical change can be solved by experts with known knowledge in his model. Adaptive requires new learning. So in comparison, an easy technical problem would be akin to type one and a complex technical problem type two. In his vernacular, adaptive would be in line with types three and four problems, which represent unknown solution spaces. I think his main area is “change” and he has several principles for leading adaptive change for example. The topic is related but not the same angle I covered in this webinar.

Q: Any book or internet articles or training on how to develop good KPIs?

Art: I personally have no books on the topic. LEI might have some reference material at lean.org. Quite a few books on this topic come up with a Google search. The old George Doran “SMART” acronym is a simple place to start — specific, measurable, attainable, relevant, time bound. His original one was different but various similar versions exist. There is even a KPI.org website.

Q: What is the survey you mentioned to find out what type of problem solver I am?

Art: The Kolb Learning Preference Survey is the one I referenced. However, keep in mind it is built for a different purpose than I use it. I merely noticed that the learning styles in the survey identified also line up with different types of problem-solving approaches.

Q: On the Kolb matrix, is one quadrant better than the others? My thinking was that we need all four working together to achieve success.

Art: I don’t think one quadrant is better per se. Much like situational leadership, it depends upon what situation you are facing. Similarly, in the situational leadership framework model, no one quadrant is best. You are to assess, diagnose the situation, flex to the right style and perform the right style to the situation, etc. Problem solving is similar in my opinion.

Q: Where is the site for the Kolb quiz?

Art: There is no quiz; just a Kolb learning preferences survey. Various types can be found on the internet floating around but the official ones come from the Kolb people. There is a site https://learningfromexperience.com that probably has it for sale.

Q: How does type four problem solving link to any initiatives under industry 4.0?

Art: Wikipedia defines Industry 4.0 as “a name given to the current trend of automation and data exchange in manufacturing technologies. It includes cyber-physical systems, the internet of things, cloud computing, and cognitive computing. Industry 4.0 is commonly referred to as the fourth industrial revolution.”

I’d call a lot of things happening under this term as open-ended innovation or type four. However, once any technology is developed and deployed it will suffer the same set of fairly predictable circumstances. People will have to troubleshoot certain issues, then solve harder gap-from-standard conditions, then sometimes incrementally raise the bar annually, etc. Then we’ll be talking about the next level of innovations and Industry 5.0 but probably after I am dead and gone.

Q: How is Toyota adjusting to the digital transformational techniques and technologies that deal with robotic process automation, machine learning, and AI?

Art: I have no recent information on this topic. There was a new special group formed last year in Toyota to start thinking about topics like this.

Q: Does the 3P methodology fit into the type four problem-solving method

Art: Most 3P stuff (not all of course) aims at some kind of type three or possibly type four situations. It just depends upon whether it is optimizing existing resources beyond standard (type three / kaizen) or emphasizing a radically new product or process (type four).

Q: Great presentation. Does the book contain more examples of each type of problem?

Art: Thanks. I try to make the concepts clear with very general examples that people can relate to. Pleasing any one crowd or specific sector is often difficult. Also, it is not really practical for me to make an example for each industry segment per type. I just don’t have the bandwidth and the book would probably get bogged down. I hope to recruit people to supply good examples from different cases and share them. I have some volunteers from the construction industry, pulp and paper etc.

Q: Do you think you need a standard approach for training or pursuing each type within an organization?

Art: It comes down to what is meant by standard. If it is an overly prescriptive way of enforcing compliance of one way, then it *can* do as much harm as it can good in my opinion. The other definition of standard is “basis for comparison.” I think this latter sense is needed but people can solve type two problems with different approaches such as 8D, Toyota eight step, six sigma, DMAIC, etc. What you tend to use in my experience is usually what you were first trained in and what learning preference you have.

Q: Six sigma is one of the most abused tools around. An incredible waste of resources and time when misapplied.

Art: I sadly agree but only when misapplied. Toyota is very good at what we called SQC (statistical quality control) back in the day. You just can’t solve certain problems without this approach. I worked on production lines that had six sigma levels of capability and quality and it was no accident. Toyota recognizes the need for this going back decades before the West became infatuated with the term “six sigma”. Some difficult problems can be best resolved by statistical OVAT / MVAT methods.

Q: Do you have any thoughts on type four problem solving for innovation in healthcare?

Art: I think it is sorely needed! I wish I had a great answer. I suspect the industry structure and method of payment, etc. have to get defined for more competition to emerge and drive better innovation. I do think that Edison was right to observe that necessity is the mother of invention. I think we are seeing innovation but with very high costs, unfortunately.

Q: Don’t you find that waste elimination and value creation for customers get lost in this model?

Art: Not really. Remember this is not a replacement for any existing overall lean framework. This is merely dealing with organizing the types of problems experienced during any transformation or daily management occurrence. Type three is where kaizen and waste elimination fit in the strongest. Many organizations rush to do this without an adequate base of ability or systems in types one and two and that is when results tend to regress back to the original state in my opinion.

Q: Have you seen any difference in applying these types when it comes to a physical environment compared to a virtual environment?

Art: Conceptually the model is the same. The difference in a physical environment is the ability to apply all five senses and a fuller experience set? Virtual tends to be more about visual and mental aspects. I’d have to learn more about the virtual environment in question to be more specific.

Q: How would you characterize the agile software development approach with respect to the four types of problems?

Art: If I recall they have their four values, 12 principles, and dozens of various concepts (iterative, short feedback loop, etc. ) I think it is fine as an overall approach for their situation. I am not trying to make a grand transformation model or overall approach for example. I am just framing problems in a way that tends to fit in a variety of situations whether it be sports, military, healthcare, service, manufacturing, etc.

From my experience with software development and deployment, all four types of problems exist no matter what the approach. Bugs exist and get fixed quickly or calls come into the help desk for support (type one), serious gaps and real problems exist and are closed as they are found (type two), improvements are made to existing products annually as upgrades (type three), and sometimes entirely new products, languages, or tools are developed (type four). Hope that makes sense.

Q: Type four or innovation … how do you see this integrated with agile teams? Are they more types one and two?

Art: Unfortunately, people get a framework in their heads and “sometimes” it becomes a set of blinders. The Japanese have a specific phrase for this — “kata in hamaranai” — or don’t get stuck in any one method. I separate types three and four in the following fashion: In type three you are primarily optimizing existing resources in the time frame of this week, month, or quarter, or at most, a year. Type four innovation (depends upon complexity and industry, of course) usually takes a bit longer and is entirely open-ended resulting in something better, not just incrementally optimized. However, all types overlap – one and two overlap, two and three can overlap, and three and four can overlap at the margins. But as my innovation friends like to say there is “innovation” and then just “everything else”.

Q: Do you have any experience teaching the four types of problem solving to non-manufacturing folks, such as a health insurer or government agency? I train on A3 and 8-step problem solving with these types of clients and find it challenging to help them gain mastery of gap-from-standard problem solving. You’re smarter, so just curious what you do.

Art: I doubt I am smarter. The trick is to find the right language, problems, and ways to work with them so they can gain ability. I have worked with government agencies such as the Department of Energy and specifically national laboratories. It worked very well there for the different parties I dealt with. However, I honestly don’t have a set answer on how to adapt to any given situation. Normally I just use my experience and diagnosis of the situation to figure out what works in light of their current state.

Q: Great work Art! I wonder how AI and big data impact problem-solving. What’s your opinion?

Art: Thanks. I don’t really know. More data can open a lot of doors and ways to analyze things. Sometimes that allows for new patterns and insights to occur. I hope this is true (safely) in healthcare for example. I think it will impact some industries and sectors (e.g. software and AI, etc.) more than others. But all will no doubt be affected.

Q: Do you recommend teaching one method of problem solving (like A3 thinking) throughout the company to set a standard and get everyone at a base level?

Art: I used to but not so much anymore. A3 or DMAIC or kata or 8D or PDCA preference is often driven by what you first learned and your own learning style preference. I may be naïve, but I was hoping that with the framework the blinders might come off for some people and they could flex to the right approach depending upon the situation at hand. Again, I am probably naïve on this hope.

Q: Toyota uses front line resources to do types one and two problems. Is a dedicated skill set and set of resources required to address types three and four?

Art: Tough question to answer in reality and probably depends upon the company and where they are in the journey. For example, I had to do types one, two, and three in my career at Toyota. I think that is true of everyone in Toyota once you get to supervision in any area. The closest thing to a type four problem for me would have been a new software system we developed in maintenance for overseas support. Or simply participating in new model launches. The company also encourages creative ideas and innovative thinking no matter how small. The counter argument would be that only certain teams get to work on new products like a Lexus or a Prius or the Mirai in the early stages.

Q: What is the 8 step problem solving process that is used by Toyota?

Art: Tracey Richardson teaches a lot of good classes on this for LEI and other places. The internet is awash with various versions.

Q: Regarding QC Circles at Toyota, do they work on four types of problems?

Art: QC circles were aimed at the shop-floor employees with facilitators to help. It would focus on type two problems within their realm of control – usually, quality problems like scrap, rework, customer defects, etc.

Q: Hello Art! What are your thoughts on the four types of problems and levels of managing increments of time (days-weeks-months-years) and hoshin thinking?

Art: I think it lines up well with Toyota’s notion of time management in leadership. For example:

- Win the minute (standardized work cycle)

- Win the hour (plan versus check board)

- Win the week

- Win the month

- Win the quarter

- Win the year

The tighter time frames often deal with good type one approaches. And I fear people don’t realize how good Toyota is at the type one stuff. A lot of the type one responses I see when I visit Toyota are better than the type two responses I see in other organizations.

Q: Hello! How can a state of mondai-nai (no problem) be achieved when we consider type 3 and 4 are about constant improvement and lifting the standard?

Art: I am not sure I follow the question? Mondai-nai (no problem) would be considered a problematic attitude in Toyota. Proper problem awareness is taught, not the state of “no problem”. Japanese coordinators back in the day threw a fit if/when people said “mondai-nai” even as a joke. Mr. Cho (Fujio Cho, honorary chairman of Toyota Motor Corporation) used to say “no problem” = “big problem” for example.

Q: Is it safe to say that the 8D problem solving methodology involves both types one and two thinking?

Art: That was an interesting one to research. There is some interesting history I won’t go into, but you are probably aware of its origins and development. Today it does seem to straddle both fences somewhat with the insistence of very specific steps or actions focusing on containment for example. I think that is likely due to its original roots in handling non-conforming material disposition, etc. Not all problems require containment (e.g. productivity, downtime, on-time delivery), but this was something they wanted to address and make people think about in the modern versions. I normally put containment emphasis in a type one approach and short-term measures as it gets to a better condition but not a cause. It tries to protect the customer. The rest of 8D goes for root cause and type two thinking. Most other approaches have a corrective action or countermeasure step and part of that phase includes some consideration of short-term countermeasures such as containment and longer-term permanent recurrence prevention ones.

Q: What else can you improve in factory production when you already did SMED changeover reduction, flow, pull kanban, and TPM?

Art: One mentor named Isao Kato chastised me on many occasions that improvement is endless. The only limit was my mind and will. Toyota is remarkably good at staying focused and finding new things to work on. Pick an area: safety, quality, cost, productivity, delivery, human resources development. Plus, every new model launch every few years brings its own set of problems and opportunities.

Q: Do you have any books or material on the six thinking hats?

Art: Edward de Bono is the master! I am a huge fan.

Q: What’s your opinion about FMEA as a problem-solving tool?

Art: I think it is a great tool especially if it surfaces a problem before it occurs. I cover it in the history section of the book. Toyota has a newer version of this called Mizzen Boushi which is really aimed at pre-occurrence prevention; a kind of FMEA on steroids and focused on change points, interfaces, and critical regions. I touch on it a bit in the history section.

Q: Is the thinking for type two problem solving different if your standards are “fuzzy” or not well defined?

Art: When standards are fuzzy it can be difficult to define problems in a rigorous quantitative manner. The gap gets expressed in a qualitative fashion. Sometimes this is okay and somethings it does cause difficulties. I use the acronym AQD (analytical quantitative and detailed) a lot when working with people to define problems.

Q: Am I understanding the problem-solving techniques properly? Can I use one type on one issue while working on another problem using a different type?

Art: Some problems can be addressed by just one type of approach. Some might start as one and morph into another type. Some might require type one thinking (put out the fire) to buy time to get to the real issue.

Q: How do you convince an organization that one type of problem-solving methodology is not always appropriate?

Art: I use the framework, various examples, and assess their styles up front via survey. I also analyze how effectively they have solved problems in the past, which requires examples and homework, to show various strengths and weaknesses.

Q: I see some similarities between value-stream mapping and the jobs-to-be-done methodology in regard to how a process or job can be broken down into steps and optimized. Have you come across this comparison? Any thoughts?

Art: Value-stream mapping can frame a variety of problems. It was originally called material and information flow analysis in Japanese and aimed at flow — takt time and pull system problems, such as lead-time and inventory. It can frame others as well, but it is strongest at those. I put it for the most part in type three but it can frame others as noted.

The work to be done framework with its eight parts looks for innovation in each step. In that sense, it is considering type four situations. However, a lot of their basic language (simplify, sequencing, eliminating, etc.), harks back to work simplification and improvement concepts that are quite old and mid-20th century. I cover some of those frameworks in the book. What is old is new again sometimes. But timeless.

Q: Why not use only six sigma?

Art: I can only suggest you re-watch the first half of the webinar for my comments on this topic. Why not only use TRIZ? Why not only use PDCA? Why not only use kata? Why not only use only one style of leadership? Why not play golf with only a 7 iron?

Q: How do you sustain a problem-solving culture?

Art: My former colleagues at McKinsey wrote some material on this back in 2014 or so. I think it was entitled “Building a Problem-Solving Culture That Lasts.” You can find it on the internet by Randy Cook and Alison Jenkins. David Mann wrote a book on “Lean Culture.” You might try those for starters. I don’t think anyone has truly cracked the code. In that sense, it is amazing what Toyota has done for about 70 years now from 1950 onward.

Q: Interesting that there is no reference to Shainin in this discussion on different problem-solving methods — any thoughts on this?

Art: I left out quite a few people I’d like to include in the history section of the book. Taguchi in Japan for example. Phil Crosby in the U.S. There are a lot of deserving names in the innovation and design thinking arena as well. Many unforgivable sins and omissions! Unfortunately, as much as it interests me personally the editors and people who reviewed the book simply did not care for all the historical detail. This history section just kept getting shorter and shorter. Unfortunately, this meant leaving out some.

Q: What is the name of your LEI book?

Art: Same as the webinar; Four Types of Problems.

Q: One last one … what style of Jiu Jitsu do you practice?

Art: Brazilian Jiu Jitsu. I learn at Checkmat founded under former world champion Leo Viera and his group of instructors. Most of the time I train specifically under black belts Robson Rodrigues and Joao Vianey at Checkmat Buena Park. Please drop on by some morning! I am in the old man’s class.