The next-best approach to having a Sensei guiding and coaching you, this immersive, interactive digital course gives you a comprehensive overview of every step of work process improvement.

You’ll learn how to improve a work process by observing; visually capturing and mapping the current state; envisioning, mapping, and validating the future state with others; setting target KPIs; conducting plan-do-check-act (PDCA) experiments; updating standardized work; and sharing success.

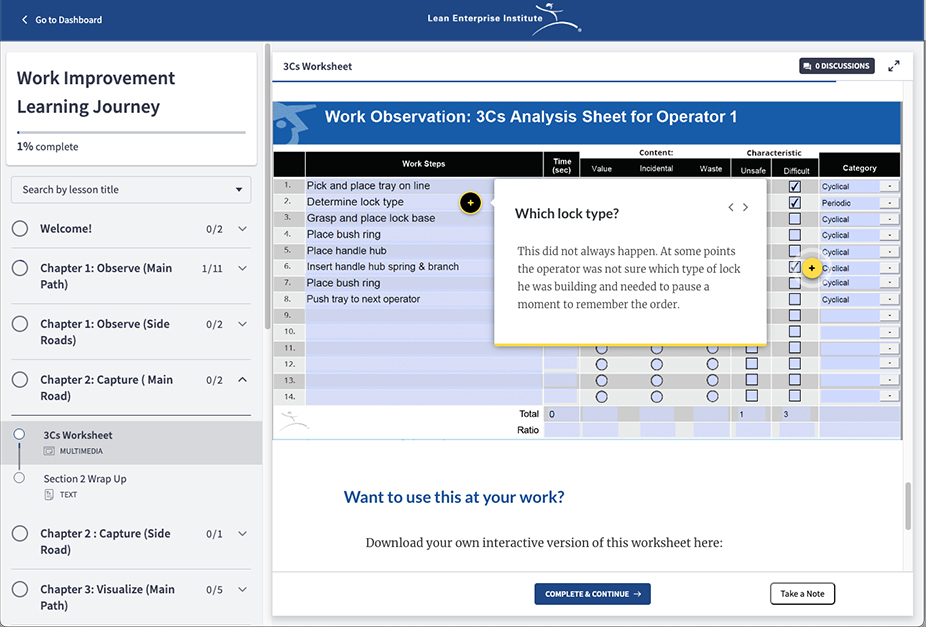

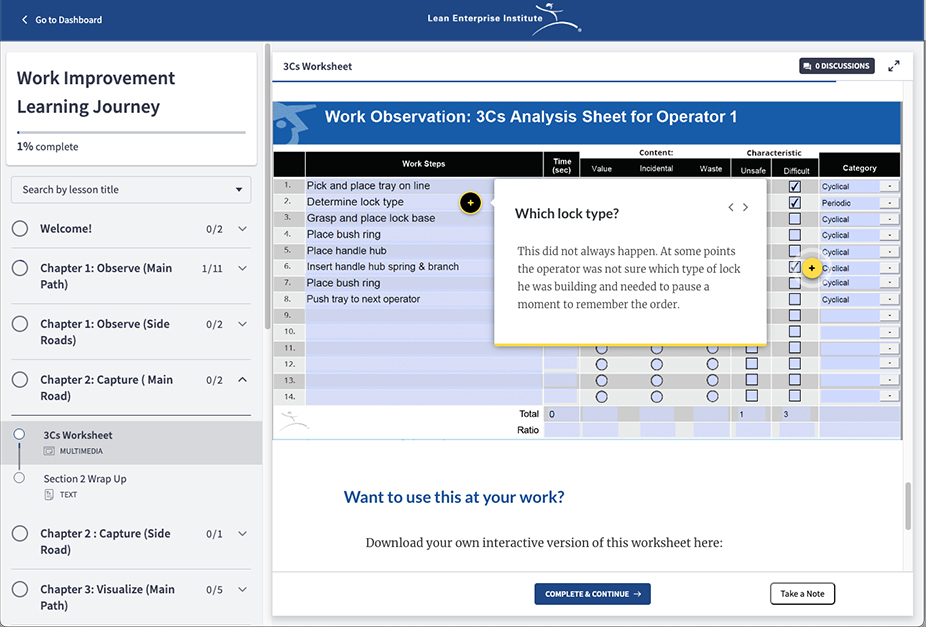

Through immersive, interactive stories of genuine business cases from various industries, you’ll engage with short, precise learning materials that explain and illustrate critical concepts and then complete practical, interactive exercises to reinforce your learning. Throughout the course, you’ll get guidance and downloadable documents to help you apply what you’ve learned in your workplace.

This course enables you to improve your efficacy at work by providing you with the tools and practices necessary to identify and solve problems that arise in the workplace. As you analyze problem-solving situations, you’ll develop a lean-thinking mindset and gain an in-depth understanding of the critical principles, practices, and tools you need to improve work processes.

Who Will Benefit?

- Leaders, from mid-level managers to top executives, including continuous-improvement and human-resource leaders, seeking to level up their team’s knowledge of lean work improvement thinking and practices.

- Beginners lean practitioners who want to enhance their career prospects by mastering work improvement using lean thinking and practice.

- Lean practitioners who want to enhance their career prospects by filling in learning gaps or refreshing their knowledge about the lean approach to work improvement.

What Will I Learn?

Completing this course will help you:

- Develop your lean/continuous improvement mindset.

- Enhance your practical, hands-on use of lean practices and tools.

- Establish the habit of using lean methods to improve work processes.

- Discover how to improve work processes holistically, not just to make spot improvements.

- Understand how lean/continuous improvement applies to organizations in various industries.

The learning journey comprises nine segments. Throughout we stress the fact that there are several approaches to the steps of Work Improvement.

Completing the entire journey will take an estimated minimum of 4.5 hours. Learners have the option to engage with additional resources, hands-on exercises, and reflection questions; as result, the time will vary.

Welcome

5 minutes

Get set up for success

I. Observe

60 minutes

3 Cs, Empathy

Observe directly and notice what impedes the flow of value to customers

II. Capture

15 minutes

3 Cs framework

Record data that explain the current state

III. Visualize

30 minutes

VSM, Production Analysis Board, Combination Table

Making your observations visual helps to spur focused discussion and problem-solving based on fact.

More ways to

visualize (optional)

50 minutes

Operator Balance Chart, Fishbone, Spaghetti Diagram

We need to be flexible with which tool we use.

IV. Validate

30 minutes

Humble Inquiry, social-technical system

Listen to those closest to the work; collaborate BEFORE experimenting.

V. Align on Gap

20 minutes

Problem breakdown; defining a gap

Breaking a problem down into smaller parts makes it easier to measure (and therefore improve upon).

VI. Set Target

15 minutes

SMART goals

Determine a clear and measurable goal to keep experiments focused.

VII. PDCA /

Experiment

15 minutes

ERACS

ERACS is the vehicle that moves our current condition closer to the ideal.

VIII. Share Success

10 minutes

Model Line

Share the success of the improved workflow to foster a continuous improvement culture.

IX. Update

Standardized Work

30 minuties

Job Instruction and Job Breakdown Sheets

Update standard operating instructions or procedures to reflect the new and improved workflow, ensuring that the improvements remain sustainable

Wrap-Up

10 minutes

Try to use your learning within a case study