Be among the first to get the latest insights from LEI’s Lean Product and Process Development (LPPD) thought leaders and practitioners. This presentation was delivered to subscribers of The Design Brief, LEI’s newsletter devoted to improving organizations’ innovation capability. It is the fourth of five in a series on process development entitled “Making Things Well,” focused on developing superior processes as part of the product development process, specifically the skills of tool, mold, and fixture makers, special machine designers, manufacturing engineers, and everything that goes into knowing how to turn a concept into reality.

Boeing’s MAX 737 is grounded again. This time the problem (the known problem) was with a manual assembly operation (four very missing bolts) in the factory. Everyone from Boeing execs to the FAA to congressional leaders is apologetic: “We thought we fixed everything in 2020” when the problem with the MCAS flight stabilizing system was fixed. The root cause they identified at that time was that “over trusting the pilots” led to software design decisions that were risky, that left the door open (sorry) for serious things to go wrong.

The problem and the fix

If the problem was “excessive trust,” what is the fix? If trust is the problem, you’d think the fix would deal somehow with it. Currently, the fix being proposed and accepted by all hands on deck is to add more inspectors. We can also, the logic goes, add more quality inspection steps in the design and development phase. Add more inspectors in the plants, and more audits in engineering. That will fix the problem. Or so goes the assumption.

But will adding inspectors and inspections fix the problem? What if, rather than adding inspectors (whether from the outside, from the FAA, or inside) at the end of the process, each of the 12,000 operators in the factory could be an inspector? Upstream, what if each engineer (software or hardware) were responsible for ensuring that quality is built in at each step?

To assure the needed quality of both design and build, Boeing needs effective mechanisms/processes and skills along with the right mindsets and behaviors. Together, these will ensure better quality performance and lead to an overriding culture of quality. Additional inspectors may be a necessary redundancy (to some degree, after-process inspection will still be necessary), but they will not replace the need for building in quality at the source.

But will adding inspectors and inspections fix the problem? What if…each of the 12,000 operators in the factory could be an inspector…what if each engineer (software or hardware) were responsible for ensuring that quality is built in at each step?

The good news is that we know the means to achieve quality at the source at Boeing. But, while adopting the means is possible for Boeing, doing so will require much more than merely adding more inspection – it will require a massive effort that is both top to bottom (of the enterprise) and beginning to end (of the process of developing and delivering the product).

Building quality into the product and the process

A lean business system begins with assuring quality by building it in at the source. The factory tools and practices to achieve built-in quality are well-known among lean aficionados, if not manufacturing professionals in general. The design and engineering practices to ensure the same are much less widely understood or practiced.

Speaking of “process,” we should note that there is a process to produce the product and there is a process to develop the product (the product development process), and, sorry, a process to develop the processes to develop and produce the product. Finally, there is a management process that (hopefully) makes it all work together.

It is obvious that you’re in trouble if you can’t manufacture your product. Cars may not start. Worse, they may not stop. Planes may fall out of the sky. And if we make products that that no one wants (think Nokia and Blackberry after Apple introduced the iPhone) your business won’t be in business for long (Boeing is lucky to have only one competitor in the global commercial aerospace business).

In his book Producing Cars at Toyota – Exploring Product Development (in Japanese only), Toyota’s former head of Body Engineering and president of Toyota Technical Center USA (TTC, where he was my boss) Kunihiko Masaki describes the Toyota way of developing vehicles. According to Masaki, the entire process begins with the principle of (you guessed it) building in quality at the source. Everything follows from that. Each step is designed and executed according to the principle that each process will deliver perfect (as designed) quality output to the next step (person) in the process.

Operating that way has obvious benefits and those that are less so. Most obvious and important, product quality delivered to the customer will improve. This will delight customers (who will hopefully purchase from us again) and lower costs (service and warranty costs, obviously, but also production costs, through eliminating rework). Moreover, operating this way also motivates each employee by providing meaningful work –- work is designed such that each individual owns the quality output of his or her effort, in service of providing great value for customers.

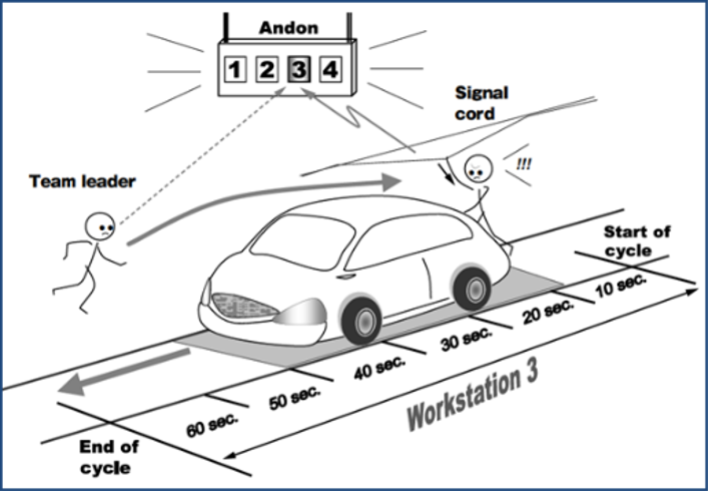

In factories, this condition is achieved by designing each job so that quality output is knowable and achievable. Work is standardized according to the best-known method and given to the operator along with the instruction to make it better, solve problems, and make improvements. But the first and foremost instruction is simply: “Stop and call whenever you encounter any kind of abnormality; someone will come to your aid immediately, within the cycle of your job.” This is known inside Toyota as JIDOKA – a principle that entails infusing each process with ownership of quality output (more on jidoka later).

On an assembly line, this means the timing, the work sequence, the amount of parts/components (and all stuff), as well as the output, are specified with clarity. Any situation outside the specified parameters is an abnormality. At the first sign of any abnormality – stop, contain, notify, and wait for help. Boeing has long been trying to break its production floor habit of breaking the sequence of work traveling along its assembly lines, a practice that creates opportunities ripe for things to go wrong.

At Boeing, there is a term for situations such as this one, when work is completed out of the production line’s ordinary sequence: traveled work.

“The folks on the line, they know what it is,” Boeing Chief Executive Dave Calhoun said in a Wednesday address to employees. “It’s uncomfortable. It creates opportunities for failure.”

For years, Boeing executives have tried and failed to break the habit. Four years ago, in the aftermath of a pair of fatal MAX crashes , Boeing laid out five values central to improving safety. Number three on the list: eliminate traveled work.

Boeing’s traveled work could not be further from Toyota’s jidoka concept – stop for any abnormality, contain and whenever possible fix it on the spot, even if it means bringing production to a halt. A complex socio-technical subsystem in its own right, the technical and managerial intricacies of Toyota’s “fixed-position stop-system” for moving conveyor line production is the topic of one of Harvard Business School’s most used case studies over the past three decades and described by Steven Spear as four key rules in use in his seminal Harvard Business Review article “Decoding the DNA of the Toyota Production System.”

But what about design or engineering work which consists of much more than a simple standardized and repeatable sequence of steps (such as designing software for a new airplane)? The time span for this kind of work is typically much longer than the 60 seconds of an automobile assembly line – the span may well be closer to 60 months. The variety of tasks and the variation in conditions with which to contend is also much greater; worse, many tasks may be performed only once. Perhaps most challenging is that most of the work may take place in the mind of the worker, invisible to the casual observer … or inspector.

And consider this: “traveled work” happens in the engineering office as well as the factory. The biggest difference is that it is harder to see, and worse, constantly shifting work around in the office is pretty much universally accepted, not just at Boeing, as normal. If the “normal” work sequence isn’t known and made visible, how do you even know that engineering design work is traveled? Answer: you don’t.

But the dangers of traveled work in the engineering design studio can be as serious as in the factory. Think of your own work – when do you make mistakes, forget a step, forget whether you completed a process or not? When we’re interrupted, from working in rhythm, working in a state of flow – then when we turn our attention back to the task that had been at hand, we forget where we were. We often get stuck. We sometimes make mistakes.

And consider this: ‘traveled work’ happens in the engineering office as well as the factory. The biggest difference is that it is harder to see.

In most engineering offices or any office, there is no overhead rope to pull, no production line to bring to a mechanical halt along with the immediate sense of urgency that it brings. The useful question to be asked in such settings is: “What functional equivalents might we identify to accomplish the same ends?” These ends include:

- Taking ownership of quality output;

- Identifying and containing immediately any abnormalities;

- Responding quickly with assistance to understand the problem, identify and try corrective measures, confirm effectiveness, and conclude with delivery of a quality output;

- Assigning to new engineers a more experienced engineer to be available whenever help is needed, and assigning the new engineer increasing complex tasks over time;

- Assuring that the mix of mechanism/process and leader mindset/behavior empowers employees, motivates them, and shows respect;

- Introducing technology with care, ensuring that each additional piece of tech actually aids rather than burdens people doing the work. The result of technology that hinders the workflow of humans is that humans end up working for the machine (technology) rather than the other way around.

Set-based concurrent engineering as a quality assurance process

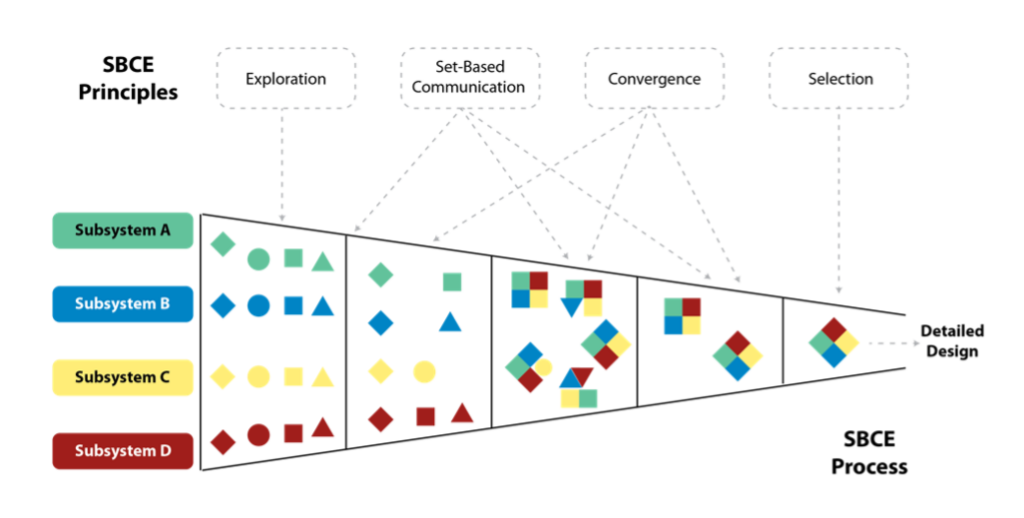

In the context of applying lean thinking to the fuzzy front end of product development, SBCE is one key process of lean development that is touted (if rarely practiced) but usually in the context of innovation. The basic idea of SBCE is to avoid jumping to solutions, avoid zooming in quickly on one solution to develop only to often find that you have to start over again from the beginning in a rework cycle. Instead, start with a set of solutions (within a defined design space) from which to go through a narrowing process, winnowing out (via a structured process of deselection) the solutions that don’t work or work least well. This way, a design team can explore more alternatives and identify more novel approaches to the design problem.

But the first value of a set-based approach is that it ensures quality. Among the set of solutions to explore, the first is simply the best currently known solution, one that we know works. Jim Morgan reports that Hiro Sugiura, who established Toyota’s production engineering organization in North America in the early 1990s, referred to the practice of “Process Driven Product Design” to ensure that product engineers designed to processes that were proven to be robust, effective, and efficient. We’d like to innovate beyond where we are, beyond the current best solution, but with the best current design as our starting point, we can begin our development process on a solid quality footing. If we can’t prove out our more innovative solutions, perhaps we don’t have enough time to fully develop them, rather than go to market with a risky product, we have a proven fallback option.

SBCE principles and process

In the illustration above, the diamond might represent the current best-known solution, to be evaluated alongside solutions of varying degrees of novelty, cost, and risk.

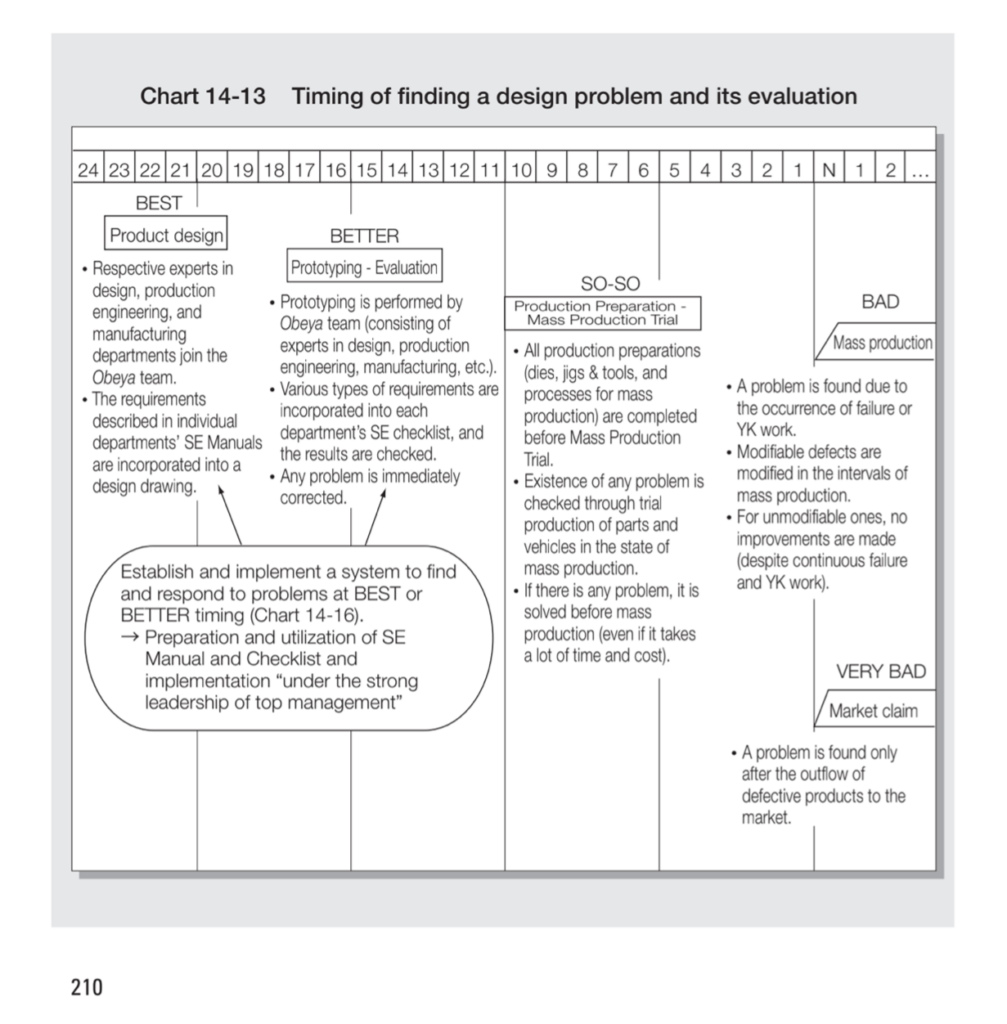

Of course, we want to innovate, to not rest on the laurels of past designs, even if they were flawless. So naturally we will stretch ourselves to challenge new, innovative designs. What becomes important, then, is identifying and addressing weaknesses in new designs (and new technology) as soon as possible in the overall process. Earlier detection is better. Quality at the source is best.

The pursuit of quality at the source in design and engineering led former Toyota engineering leader Tatsuhiko Yoshimura all the way upstream to preventing quality problems before they even occur. Known as “mizenboushi,” which means to prevent before occurrence, or “GD3,” which stands for good design, good dissection, and good discussion. In this recent Design Brief interview, Yoshimura describes GD3 and its power as an upstream socio-technical quality assurance process.

Even in the best of systems, problems can escape early detection. Sadao Nomura is a retired Toyota executive who insisted on pursuing perfect quality at the source via an obsessive focus on the critical linkages between engineering, operations, service, and back to engineering. Through processes such as making defects and quality visual, and demanding immediate action to address each abnormality occurrence, Nomura led Toyota to achieve its best-ever performance in launching a new vehicle (the Mark II/Cressida, its best-selling sedan at the time). At Toyota Forklift, Nomura’s approach achieved improvements of 98 percent in in-process quality and 93 percent in problems that reached the customer. Focus on moving quality problem identification further and further upstream is highlighted in this chart from Nomura’s highly detailed book The Toyota Way to Dantotsu Radical Quality Improvement.

Nomura’s dantotsu quality improvement process has led to remarkable quality performance improvements at other manufacturers and even software companies such as Theodo. (See the story by Fabrice Bernhard in last month’s Design Brief.)

Lessons in product and process from NUMMI

In the case of Toyota (managing partner of the NUMMI joint venture that we will explore below), most readers will know the Toyota Production System (TPS) and may have heard that there is a Toyota Product Development System. Together, they comprise a mature lean product and process development system.

A historic venture

NUMMI, the joint venture between Toyota and General Motors, has been long and widely hailed as an outstanding example of how an organization can radically improve its performance and transform its culture from bad to great. The agreement between the two JV partners was that Toyota would manage the plant and implement its famous production system. It did. And it worked wonders. The old GM Fremont plant went from being GM’s perennial worst performing plant to its best. The workforce that had been acknowledged as the worst in GM’s global system and even the worst workforce of the United Auto Workers became the best in both the GM and UAW systems.

Only one year after restarting operations, NUMMI’s performance scorecard looked like this:

- Quality — from worst in GM to the best in the company’s history and fully equal to Toyota’s best in Japan;

- Productivity — from among worst to the best in GM (40 percent better than average) and about 85 percent as good as Toyota in Japan;

- Absenteeism — from close to 25 percent to about 2 percent;

- Grievances — from 25 per week to 25 per year;

- Labor-management relations — from overwhelmingly contentious to mutually supportive.

Observers1 have focused on the role of key TPS plant floor management elements in enabling the remarkable transformation. Without doubt, the respect and genuine empowerment afforded the workers through TPS processes such as the andon and suggestion systems were powerful.

Unnoticed by most commenters on NUMMI’s success was the role of the product that was produced there. In addition to the new plant production and management systems, the plant was also given a new product to produce. A product that had been developed according to the same principles of building quality in at the source.

This was manifested in two main ways: (1) the product was designed to be assembled within a “built-in quality” production system, and (2) the engineering work was itself conducted by the same principles, but with tools and techniques appropriate for an engineering environment.

Consider these simple facts. When GM ran the plant (which it had shuttered in 1982), Fremont produced:

- Volume – 1,000 passenger cars per day on two shifts;

- Models – Four: Chevrolet, Pontiac, Buick, Oldsmobile (trucks, too, from time to time);

- Powertrains – Each brand had its own unique set of engines (V8, In-line six, numerous performance options) and transmissions (three and four-speed manuals and two and three-speed automatics);

- Body Styles – 112 (variations among two and four-door hardtops, two and four-door sedans, station wagons, convertibles, pickups);

- Options – Unlimited: the possible combination of options ran in the billions and actual order combinations in a year were said to run in millions.

Contrast those characteristics with NUMMI in its first year (the year of the remarkable turnaround):

- Volume – 1,000 passenger cars per day on two shifts (after ramp-up);

- Models – One: Chevy Nova (a rebadged Corolla);

- Powertrains – One;

- Body Styles – One;

- Options – Limited to seven option packages.

What you produce impacts how you produce it

Imagine yourself working on the old GM Fremont assembly line. Coming at you minute after minute you encounter a base model Pontiac Tempest two-door sedan, six-cylinder, three-on-the-tree followed by a fully loaded Oldsmobile F85 V8 automatic with power windows and a vinyl roof followed by a Buick Skylark station wagon. What were the odds that all the right parts would be available when needed? That the impact wrench would work properly? What (we will return to this critical question later) would the worker do if otherwise?

Contrast that picture with one of the same worker on the same assembly line, but now she’s handling parts that are always right there where she needs them, that snap together easily on vehicles that one after the other present themselves to her in essentially the same way, using equipment that always works properly, and when things don’t work right she simply asks for assistance and someone comes to help her out … NOW. I would argue that if you handed that second scenario – just the bit about product simplicity with the right materials always being there and bolting together exactly as intended – to the old GM Fremont workers before NUMMI and without TPS in the plant, the quality and productivity and worker satisfaction scores would have skyrocketed.

As simple as possible – no simpler

It would be a mistake, however, to imply that the production system Toyota installed at NUMMI was incapable of handling variety. The Chevy Nova built by NUMMI was based on the fifth-generation Toyota Corolla. That Corolla was available in Japan in a bewildering array of variants, including front-wheel drive only, rear-wheel drive only, and four-wheel drive models. In addition to the staid family sedan usually associated with the Corolla, the rear-drive two-door coupe variant became a legend that is still in demand with drifting kids and just recently inspired the design of the Toyota 86 and Subaru BRZ.

The man responsible for that iconic generation of the Corolla was Chief Engineer Fumio Agetsuma, but at the time of the Chevy Nova development, responsibility for the Corolla had been handed over to new Chief Engineer Akihiko Saito. By the time preparation for the product to be built at NUMMI began, engineering of the vehicle was so robust, CE Saito didn’t even involve himself in the project at all. He left product engineering responsibilities to his deputy, Makoto Yamada, who in turn left almost everything to engineers residing in functional engineering silos such as Interior or Body Engineering. (Note: in Toyota’s unique product development system, “chief engineers” had few direct reports and therefore had to orchestrate the complex process of developing a vehicle via leading functional departments, such as the aforementioned body or interior engineering, through a process of “leadership without formal authority.”2

With time, additional complexity was steadily added to the NUMMI product lineup. Throughout the 25-year history of the joint venture, eight different vehicles were produced. When it closed in 2010, the NUMMI Fremont plant was producing the Tacoma truck for Toyota and two small passenger vehicles, one each for Toyota and GM. Options were always kept in check (for both Toyota and GM vehicles – a practice that GM partially adopted for its full vehicle lineup) via meticulously designed option packages from which customers could make their choice (with limitations – if, for example, you the customer have your heart set on power windows, sorry, but want it or not you must also get the premium sound system).

But that complexity was necessarily added to the NUMMI system over time, nested within a carefully designed set of processes that enabled and encouraged a new suite of behaviors which in turn led to a new culture of exposing problems.

Let’s go back to that GM worker who faced a barrage of problems all day every day – parts that don’t fit, parts that aren’t there, equipment that doesn’t work, and leaders who aren’t there to provide support when needed. What was the worker to do? Step away from her work and search for help? Hardly. The line isn’t stopping. It’s clicking along at a pace of about a car per minute. It … doesn’t … stop. Neither the line nor the problems. She quite literally has no recourse. She could choose to look for the big red emergency stop button that is surely on the wall over there somewhere. And she could press the red button. And the line would stop. And someone would surely come to “help.” And she would be informed that every minute the line is stopped costs the company thousands of dollars. And she would surely never press that button again. Is there any wonder that the quality was so poor, absenteeism so high, the culture so toxic? All of that changed when NUMMI brought in TPS.3

This scenario presents a glaring contrast with Boeing’s condition of traveling work and missing bolts that led to another grounding of the MAX737. The mechanisms or processes combined with a quality-first mindset add up to radically improved performance in the near term.

Amy Edmonson describes psychological safety and, often overlooked, execution-as-learning, recognizing the key role that operations – how we go about doing things – plays beyond what we usually see on the surface. In the longer term, micro habits lead to macro culture change.

In the bestseller, Smarter, Faster, Better author Charles Duhigg relates a powerful story from NUMMI’s early days. NUMMI leaders at all levels and functions spent weeks at Toyota in Japan learning about the system they were to install in Fremont, California. One of the most important, and dramatically different from conventional, was this “stop the line” process, often known as “andon.” The process entails a mechanical andon system, one key piece of which is a means of knowing job progress and making normal from abnormal apparent at a glance.

From the very beginning, NUMMI installed the mechanical process, but the process is meaningless unless the people doing the work use it to spot problems, contain them, and call for help, after which help will arrive (within the job cycle). In the earliest days of Nova vehicles being assembled on NUMMI’s new conveyor line, an unusual problem arose – there didn’t seem to be many problems. The newly hired American managers and their GM counterparts took delight in this – they had never seen such a smooth launch. But Toyota’s Japanese managers could sense, and see, that something was wrong.

Micro habits lead to macro culture change.

In the later-to-become legendary story that Duhigg relates, NUMMI president Tatsuro Toyoda (son of the auto company founder) was walking the line when he spotted a worker struggling with an assembly. The worker and especially his team leader and even more especially the assembly shop manager saw what was happening, which was that the president of the company was watching and began sweating. President Toyoda encouraged the worker (and team leader) to pull the rope. To use the andon system to contain and call for help. After the rope was pulled, as everyone stood around wondering what would happen next after he had stopped the entire assembly line, President Toyoda thanked him. Thanked him for showing so much respect for the customer, for the company, for the product, for NUMMI by stopping production to build in quality at the source. Word of that incident spread to the plant like wildfire. Before long, andon ropes were being pulled routinely throughout the plant, throughout each day. And, it should be noted, “excessive trust” wasn’t a problem; deep mutual trust (not blind trust), and mutual resolve to pursue trust were the enablers. It should also be noted that these practices and routines are means of instilling the change of habit (See Duhigg’s other bestseller Habit or Mike Rother’s Toyota Kata) that Boeing leaders say they want.

In addition to the powerful mechanical process of the andon system, the underlying, more difficult to see “software” of mindsets and behaviors (think also of the “management system” and insert the word “culture” if you wish) brings the process to life. Contrast this with the mindset/behavior of so many traditional leaders who too often seek to blame rather than ask how they can help.

Origins of quality at the source at Toyota

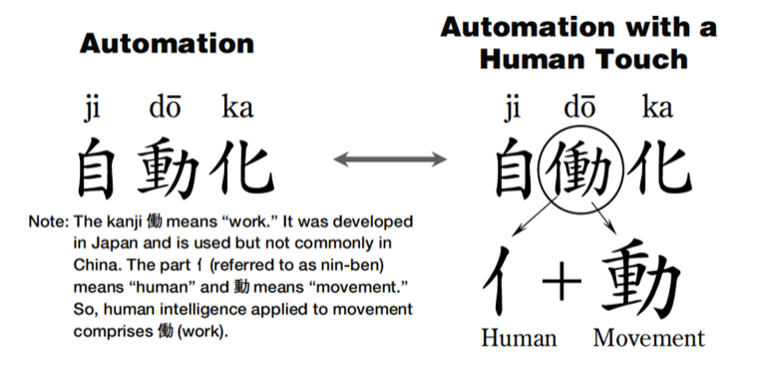

Most readers will know TPS and its two pillars of JIT and jidoka and its foundation of stability from standardized work and continuous improvement and innovation. As Toyota defines TPS on its website:

The Toyota Production System (TPS) was established based on two concepts: “jidoka” (which can be loosely translated as “automation with a human touch”), as when a problem occurs, the equipment stops immediately, preventing defective products from being produced; and the “Just-in-Time” concept, in which each process produces only what is needed for the next process in a continuous flow.

As TPS begins with jidoka, any effective system of production begins with building in quality. The Toyota approach to quality has its origins in the founding of the Toyoda group of companies during its formative period in the late nineteenth century. Sakichi Toyoda (1867-1930) is as known in Japan as perhaps Eli Whitney in the US or James Watt in the UK. Sakichi was struggling to follow in the footsteps of his father as a carpenter when the inventor’s bug bit him. Sparked by two inspirations, one personal and one of national ambition, Sakichi got a patent for his jidoka invention in the early 1900s.

His first inspiration was personal, with images of his mother and other women weavers in his hometown struggling at their hand-operated wooden looms. But his more immediate inspiration was one of national ambition as Sakichi was emboldened by Japanese government policies that encouraged domestic invention in order to compete in a global economic and political environment in which Japan was seemingly hopelessly behind. The first problems he chose to solve? How to build in quality at the source and provide workers with jobs that are respectful of their humanity.

Jidoka – a concept for the twenty-first century

Achieving perfect quality that is built in – not reworked upon later inspection – is one of the two basic purposes of jidoka. The other purpose is a matter of respect for the humanity of the people who do the work of producing the product. But, first, a word on this curious word jidoka.

Jidoka as a term can cause confusion even in Japan because it is a made-up Toyota term (a Japanese portmanteau) that is based on the Japanese word and kanji for automation. Jidoka as a concept holds that the work of a machine – or the function of any technology – should be separated from the work of humans, with assurance made that machines or any automation should work for humans – not the other way around! This respect for humanity, and this way of thinking about the design of work, is the foundation of all work at all Toyota companies.

Build great products in the USA – design great products in the USA

The same methodical approach that Toyota applied in bringing production operations to the US also applied to the challenge of transplanting the full Toyota Product Development System. The NUMMI experience again showed the way forward as Toyota’s Japanese engineers worked with counterparts from GM to design mostly interior components and source them locally. This was Toyota’s introduction to the second major learning (the first was how to work with American workers and managers) the company was seeking from the joint venture: how to work with American suppliers.

The first step to working with American suppliers was simply to get to know them. In those days, it was common in the global auto industry for OEMs to work primarily with their own core group of suppliers. This was certainly true for both GM, with its GM components group of vertically integrated suppliers (at the time, GM produced about 70 percent of the total vehicle content in-house) and Toyota. Toyota, for its part, had close relationships (including even interlocking stock-holding arrangements in what is sometimes called a “vertical keiretsu”) with about 65 core suppliers (along with close business ties with a couple hundred more).

When production began at NUMMI in 1984, most parts and materials were shipped from Japan and placed in a holding facility close to the plant. Steadily over time, more and more of the parts and materials were localized. American suppliers (of door and trunk seals; Injex was one such example) built facilities to supply Fremont from close proximity, beginning the process of replicating Toyota’s intricately designed JIT system of supply with its implications for close OEM supplier relations.

NUMMI’s success led Toyota, practicing plan-do-check-act (PDCA) even at this scale of major investments and initiatives, to establish wholly owned factory operations in Kentucky and Ontario which in turn led to establishing engineering and R&D operations in North America. By the early 1990s, the company made the big leap to develop engineering and product development capabilities at the Toyota Technical Center in Michigan.

If establishing NUMMI and the subsequent factories were momentous decisions, they were decisions that Toyota made with a substantial degree of confidence. The methods, both technical and social, to establish a high-performing factory felt to Toyota like a challenge that was in their wheelhouse. The only variable of consequence was people. There were, however, some unknowns that created the need to run the experiment that was NUMMI. And the answers came quickly: yes, the factory and supply chain methods work just fine in North America.

But the work in the factory is visible and the variables are mostly controllable. An engineering center or “design factory” is a different matter. The challenges are greater, the timelines longer, the unknowns more numerous, and the stakes entailed with each error are greater. PDCA cycles are no longer defined by relatively simple, rapid 60-second feedback loops. Most challenging of all, an important gemba of the work is invisible –- the work taking place inside the head of the developer.

Toyota had already overcome these challenges, of course, at its engineering and R&D centers in Japan. But a big question remained: will those methods, successful in Japan, work with American engineers? And there was an additional piece to the challenge of the longer timelines of development work. If the time required to train a worker to satisfactorily perform the standardized work of an assembly line was a matter of weeks, it took years to develop a development engineer. Engineering leaders at Toyota in Japan liked to say that it took ten years to develop a development engineer. But if Toyota needed a fully operational product development center to complete its North American enterprise, the ten-year rule of thumb represented a problem.

An engineering center or “design factory” is a different matter … PDCA cycles are no longer defined by relatively simple, rapid feedback loops … most challenging, an important gemba is invisible –- the work taking place inside the head of the developer.

Where to begin? Where to begin the process of developing a product development center? Where to begin developing product development engineers? The full answer to these questions is beyond the scope of this article (those were questions addressed by Masaki and team at TTC), but the first principles to be targeted had to be: (1) building in quality at the source and (2) establishing mutual trust and respect among engineers and engineering leaders.

At Toyota, then and now, in Japan or elsewhere, the process of becoming a development engineer begins with the assignment of a first project (sometimes called a “freshman project”) along with a mentor from whom to learn. Through fulfilling the assignment (learning through doing, or execution-as-learning), and experiencing the mechanisms or processes such as the aforementioned GD3 and SBCE, the new engineer learns how to execute a high-quality design while working with others in a team environment. Helping and being helped (with emphasis on the latter for the new engineer), with the social system (including the building of healthy, trusting relationships) fully integrated with the technical.

There may be no physical rope overhead to pull. But the process works the same way –- the new engineer knows who to call, how to call them, and what will happen after calling. Help will arrive right away and, together, they will work through the problem at hand, with the mentor mentoring, avoiding solving the problem directly, which would thereby take ownership away from the engineer-learner. There may be other ways of mitigating traveled work in design and engineering work, but I can’t imagine one more effective and organic than this very human-centric method. In the end, the design will be the engineer-learner’s; ownership will remain with the engineer-learner. (For more on jidoka as a concept for work of the 21st century, aiming for conditions in which technology works for humans rather than the other way around, see my lean.org webinar with Dr. Lisa Yerian M.D., chief quality officer of the Cleveland Clinic. Entitled “Jidoka 2020,” the webinar features case studies from Toyota and the Cleveland Clinc. Jidoka is discussed from 32:00 to 40:00.)

NUMMI’s performance and culture changed radically as direct outcomes of the plant operations (with its robust and meticulous processes) and management (with its essential mindsets and associated behaviors) systems. But equally important was the impact of the engineering design of the product, also the result of a system of processes and mechanisms, mindsets, and behaviors. There is a reason we bother to reference the awkward “lean product and process development” over the easier and more obvious phrase of “lean product development.” Product and process are two sides of a coin, feeding off and reinforcing each other. The NUMMI example makes it clear that product and process together lead to outstanding performance.

Back to Boeing

What does all this mean for Boeing? Forever adding inspectors and engineering steps may yield some improvement in performance: fewer airplanes that fall from the air. That would be welcome, indeed. But to consistently ensure quality of design and build, to escape the endless loop of applying band-aids only to discover additional disastrously defective airplanes, Boeing needs to incorporate effective mechanisms and skills along with the right mindsets and habitual behaviors – throughout its extended enterprise. Together, these will ensure better quality performance and lead to an overriding culture of quality. Additional inspectors (whether from the outside or inside) may be a necessary redundancy, but they will not replace the need for the process and mindset changes entailed with building in quality at the source.

The good news is that there is ample reason to believe that the latent capabilities to do that are present within Boeing. After all, they did it just a few years ago under the leadership of Alan Mulally.

As industry observer and author Bryce Hoffman tells it:

Mulally relied on a powerful new management model to save Boeing: articulate a clear and compelling vision for the company, develop a comprehensive strategy to deliver on that vision, and execute on that through a relentless implementation process led by a team of talented people working together. By September 2006, Boeing was not only back, but it was also building the most revolutionary jet in a generation: the 787 ‘Dreamliner.’ And its stock was trading for more than $80 a share.

That’s’ up from its long-time low of $18 when Mulally took over.

At Ford, Mulally established the same management system, architecting the same kind of turnaround at Ford in just about the same, incredibly short, time frame. Sadly, upon his departure from each, the amount of time for each company to devolve back into similar states of disrepair was equally dramatic, quick, and depressing.

Speaking at a gathering of Ford executives, Hoffman offered this advice: “Look at Boeing, and don’t stop looking at Boeing, because if you look at Boeing, you’ll see what happens when a company fails to internalize Alan’s teachings and abandons his ‘Working Together’ model.”

Echoing Hoffman, I do hope Ford is continuing to look at Boeing. I find it encouraging for Boeing to hear current CEO Dave Calhoun calling out the details of the traveling work problem, indicating a willingness to go beyond platitudes.

I am loath to jump on the bandwagon of the chorus of voices ridiculing Boeing, today’s poster child for big company disease. It is too easy for pundits, including me, to prescribe easy-to-say yet exceedingly difficult-to-do solutions. But, indeed, escape from the endless cycle of *problem – blame – band-aid – repeat* is possible by means of a massive shift in mechanisms/processes and mindsets/behaviors to the principle and practice of quality at the source. Ultimately, you can’t inspect in quality – you have to build it in, step by step, from beginning to end, from top to bottom.

js

- Among the many observers are: John Shook, “How to Change a Culture: Lessons from NUMMI,” MIT Sloan Management Review (January 2010); Frank Langfitt, “The End of the Line for GM-Toyota Joint Venture.” All Things Considered (March 2010); Paul S. Adler and Robert E. Cole, “Designed for Learning: A Tale of Two Auto Plants,” in Enriching Production: Volvo’s Uddevalla Plant as an Alternative to Lean Production, (Aldershot, UK: Ashgate Publishing Ltd.,1995), 157-178; Smithsonian “Workers and Managers: The Crisis of Control in American Manufacturing, exhibit Oct 2, 1989 – Feb 28, 1990.

↩︎ - 2 Allen C. Ward and Durward K. Sobek II, Lean Product and Process Development (Cambridge: Lean Enterprise Institute, 2014); John Shook, “The Remarkable Chief Engineer,” The Lean Post (February 3, 2009); M. Rossi, J. Morgan, and J. Shook, Lean Product Development: The Routledge Companion to Lean Management, (New York: Routledge, 2017).

↩︎ - 3 Shook, “How to Change a Culture”; Langfitt, “The End of the Line”; John Shook, “Highlighting 100 Years of Innovation in the Work,” The Lean Post (September 2016).

↩︎

Cover photo courtesy of Boeing.

A very informative article ,would be of great help to all the professionals associated with Quality and Allied fields ,the importance of process simplification and ownership of result delivery for all to read and benefit from the article .