Dear Gemba Coach,

Is zero defects really the first goal? The number of defects doesn’t necessarily relate to the user’s experience with a product, does it?

Yes, you’re right. Deming himself writes pages about companies that achieve defect-free products and still go out of business because their “perfect” product is out of synch with what people want.

This question is actually at the heart of Christensen’s theory of innovation. He argues that when you have a successful product, you want to satisfy your best-paying customers to keep high margins – makes sense. So, you keep adding new features and solving every bug to keep the high expectations/high price clients happy.

At the same time, someone else comes in with a new tech that is buggy and inconvenient, but really cheap. These guys also want to reach the high-expectations/high-price crowd, so they’ll work at solving bugs and adding new features, based on the new tech. At some point, their progress will reach the point where you were at the beginning. Their product is not as good as yours, but it’s as good as you were when you did satisfy customers, and much, much cheaper. This is when everyone switches at the same time, the bottom falls out of your sales and you go out of business.

Now, this is just one theory and all great innovation have their own unique path. For instance, Tesla came in with a new tech at a high price – funded by crazy financing, sure, but so far so good.

It Takes a Troika

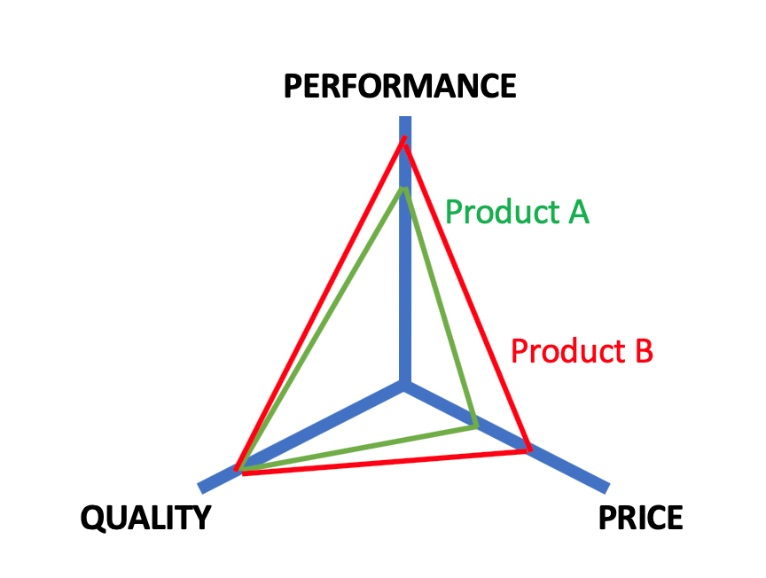

The point is that perceived quality is one key driver of a business’ success, but not the only one. To look at competitive positioning, we look at a triangle of performance, quality, and price.

Performance is about how the product really performs for the customer. Imagine that you don’t purchase a product, but that you rent a service the product does for you. In order to hit the spot, this product has to get a number of things right:

Performance is about how the product really performs for the customer. Imagine that you don’t purchase a product, but that you rent a service the product does for you. In order to hit the spot, this product has to get a number of things right:

- It has to do the job;

- It has to be safe;

- It has to be handy;

- It has to be friendly;

- It has to be liked at first sight;

- It has to develop a deep relationship with you;

- It has to be good value for money.

If you think about it, even for a simple object as a mug, this is far from easy to achieve. Let alone for a desktop computer and so on.

Mug Maker’s Dilemma

Performance means translating these intangibles, which you learn from spending time with users and using the product yourself in different conditions, as well as using competing products into deliverables:

- How much tea should the mug contain to be useful but not too heavy to carry?

- How much heat should it let out to be light but not to burn you when you hold it?

- How much space should it allow for your finger so you can grab it easily but hold it without losing your grip?

- What look and feel will make it attractive both on the first day and on the hundredth?

- How expensive should it be to fulfill all of these and still be purchasable?

If you’ve thought it through hard enough, you’ll end up with a list of “yet” criteria, with quantifiable answers – for instance “large YET light.”

The performance of the product is not a list of features that work bug-free; it’s a list of trade-offs the design handles smartly. The success of the product depends on how well these trade-offs satisfy the one larger tradeoff of a product that “carries out its traditional function YET is in the spirit of the times.”

The performance of the product is not a list of features that work bug-free; it’s a list of trade-offs the design handles smartly. The success of the product depends on how well these trade-offs satisfy the one larger tradeoff of a product that “carries out its traditional function YET is in the spirit of the times.”

Still, understanding these trade-offs counts for nothing if you don’t deliver on them, which is about meshing the various technologies to deliver features bug-free. If you have a friendly pictogram on your cup but the inking is sloppy so that the letters don’t stand out crisply, you lose the point.

Each of these design points will stem from a specific technology and how well you master it. This is where zero bugs comes in.

Many engineers try to compensate for bugs by adding further performance. Rather than fix the existing inking process that occasionally gives a sloppy picture, they’ll look for a more robust, and often more expensive inking process. Every time they increase performance requirements, they add a double pressure on the product:

- Cost;

- Interaction with other technologies for the other features.

Zero in on Zero

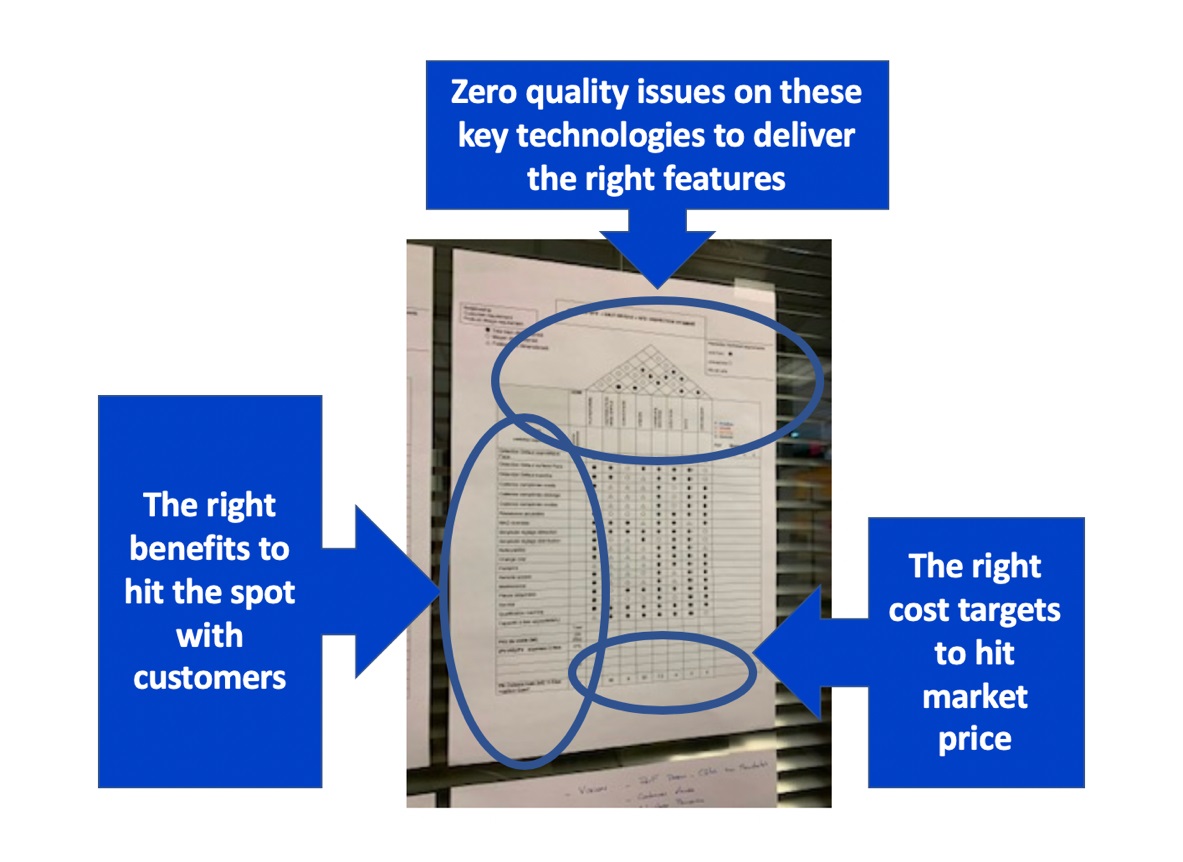

Zero bugs is essential because it teaches you to deliver on the technologies you currently handle. If you look at the Quality Function Matrix, you’re faced with two deep problems:

- Have I got the right features and the right level of performance to hit the spot with customers?

- Can I deliver on the technologies I use for zero quality issues at target cost?

On the gemba, at PRODITEC, engineers use the QFD matrix to constantly question whether they are working on the right things to capture customer interest — trying to better capture customers’ moods than their Japanese, Korean and Slovenian competitors — and then better deliver on it.

On the gemba, at PRODITEC, engineers use the QFD matrix to constantly question whether they are working on the right things to capture customer interest — trying to better capture customers’ moods than their Japanese, Korean and Slovenian competitors — and then better deliver on it.

Aiming for zero bugs is the discipline that gets you up the hard learning curve of mastering the technologies and their interactions. Zero bugs is an essential goal of your lean approach, but yes, by all means, not the only one. Without a deep understanding of what customers are looking for, zero bugs won’t save you. But it’s still the best place to start to understand what customers are after.