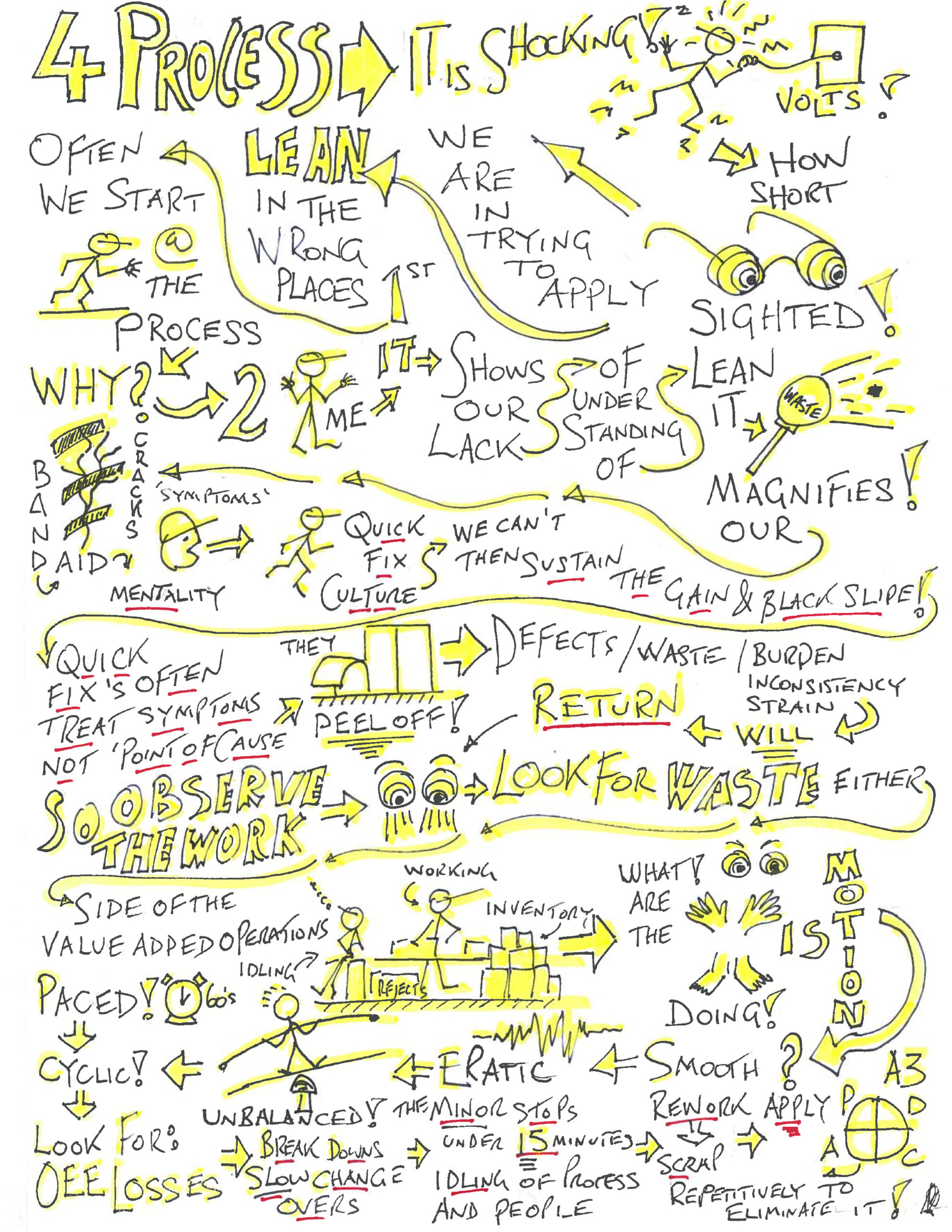

We now come to the final installment in my sketch series on areas of manufacturing waste: PROCESS.

It seems intuitive to start applying lean to our processes, right? Maybe so, but all that says to me is that we’re short-sighted when applying lean. The problem I often see is people applying lean directly to processes because they assume the waste is there – which it is. But doing this only intensifies the risk of a Band–Aid mentality. And of course, along with it, the dreaded backslide on gains. It is critically important that before you change or adjust anything in your process, you first look at your entire value stream – from goods and materials coming in, to conveyance, to storage (inventory) and dispatching your finished goods. There is always waste hidden within your value stream, so go find it and squeeze it out HARD before you apply a lot of time and effort leaning out your process.

This, in my view, is the more effective approach to waste elimination. In my experience it boils down to educating yourself on what exactly you are looking for and looking at within your value streams; learning to see, observe, and listen; and then asking productive inquiry questions. I hope my new sketch and animated video will show you more about what I mean and need to share with you all.

So once you have reviewed the sketch and gone through the animated movie, what are you going to be doing differently tomorrow based on what you have understood from my story? Use this to make a change and an impact…