The promise of a perfectly made beverage and a dedication to represent the mission of “To Nurture and Inspire the Human Spirit One Cup, One Person, One Neighborhood at a time” was inspirational – and a huge daily problem to solve.

Inside these words lie an expectation to perform at the highest levels in a very consistent way. From the coast of California to the fishing docks in Portland Maine and everywhere in between. The only true path to consistent operations and enabling those who delivered the value to the customer on the front line was to figure out how to stabilize the work.

The only true path to consistent operations and enabling those who delivered the value to the customer on the front line was to figure out how to stabilize the work.

Karen Gaudet

We had been brewing a good deal of coffee – and wasting a good deal of coffee – and still the customer might arrive and not be able to get what they asked for without a wait for it to brew.

The demand rate on cups of brewed coffee was high, there was no established way to follow a consistent sequence of steps; every café could be different, and the amount of inventory on hand, however high, still the customer experience was not what we had promised.

Prior to undergoing a lean transformation, we had work standards at Starbucks: a standard temperature for steamed milk, for example, or a standard way to brew coffee in a French Press, or a standard espresso drink recipe. However, because every location was different, each manager had developed their own way or method to get the work done. This was a strength as it enabled each location to become part of the community; and at the same time our Achilles heel when, as a company, we experienced the impact of the economic crisis of 2008.

Given the size of the company in 2008, the differences that existed in each location made it hard and cumbersome for leaders to effect system level change. Customers were expecting us to deliver a consistent experience and yet we were unable to. We would be throwing out coffee at the same time customer were telling us they could not get the coffee they wanted. Being one of the leaders to navigate through that timeframe was tremendous learning, albeit one I would hope not to repeat, given the personal toll it took on so many as we closed stores and laid people off.

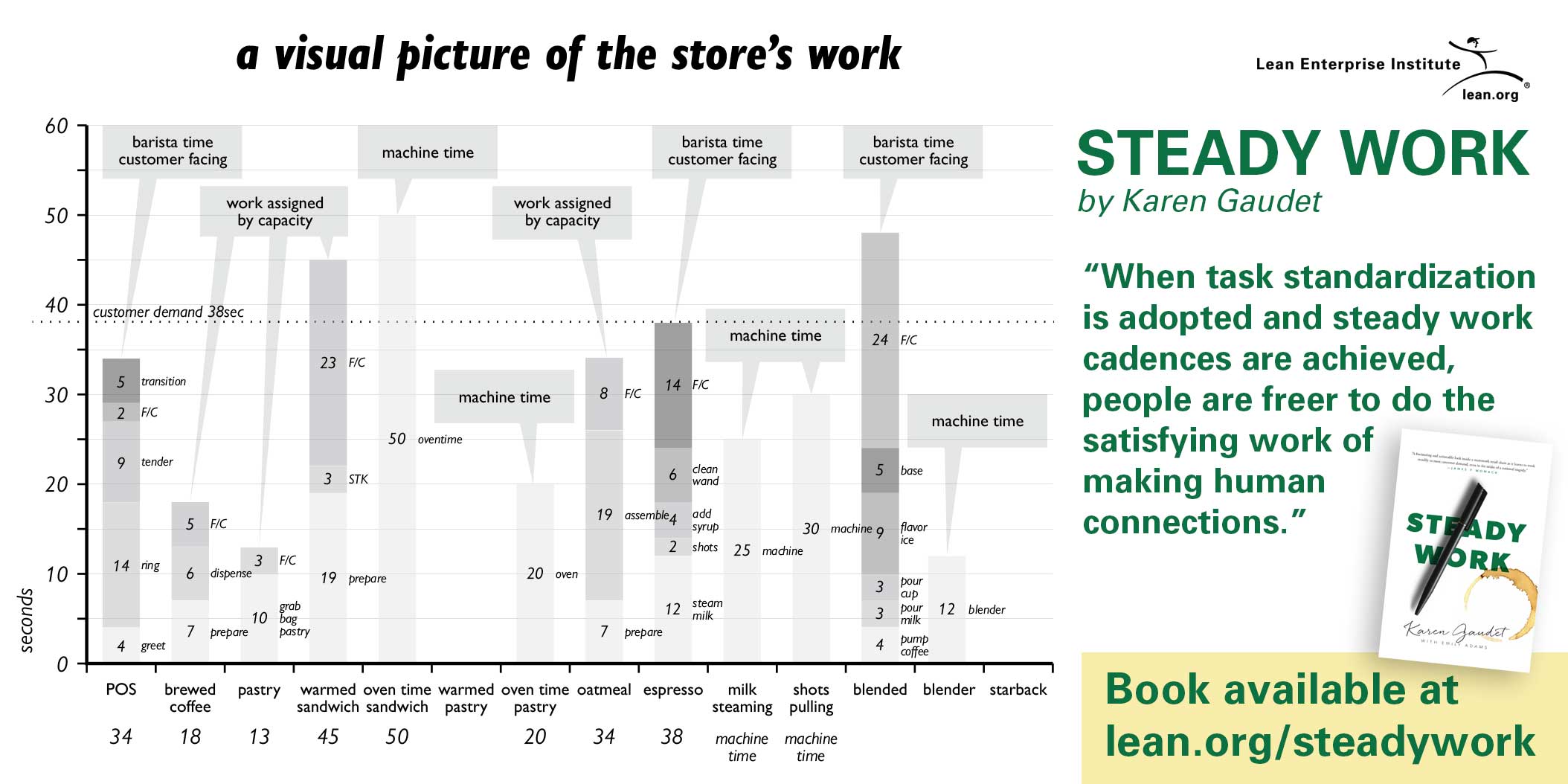

The Lean Team in Seattle had been working with operators to develop standard work routines. After much testing and time to understand the impact on the work, people, and the customers, we had reached the point of spreading the actual lean operating system to multiple locations. The operating system then took those work routines and carefully knit them together to work in concert with each other. The work standards resided inside of the routine method. A clear method of thinking was required to understand how to situationally adjust the system and solve for problems.

We wanted to ensure that partners (employees) in the field would learn the thinking behind what it took to develop a work routine, understand the parameters needed to ensure work standards and then have the ability to solve for the problems the system was meant to expose.

As with all things in a Lean Transformation there are social aspects and technical aspects of the capability needed to be successful. As my team and I built our technical understanding, this shaped the social aspects of how we applied the thinking. Given each Starbucks Cafe location was different in physical size, layout and product mix, we needed to have a fixed and flexible operating system.

The routine work of how to assemble a beverage, how to steam milk, how to fill the pastry case, how to warm food, process orders in the drive-through and more was standardized. The system pulled it together and informed, given the demand on certain work at each location, what was needed to staff at all times of the day.

As a Regional Leader I now had the ability to walk into one location and know how the work should be getting completed here and at the next location, and the next. Instead of not knowing what to expect, as each location previously would be different. Myself and my team of leaders to include each of the café managers and shift managers all knew the thinking behind the developed routines, so we were operationally of like mind.

The standardization of the work routines and the system level thinking provided us the freedom to focus on connecting with the customers, build greater community supported relationships, look for innovation in the problem-solving process and drive to refine our performance of the system.

My peers and my collective team were better able to add value back into the process because we could see and understand how the work was getting done. I did not need to assume how the work was getting done. I could focus on the system level problems that were mine to solve and facilitate the problem-solving that was our team members to solve.

There is an assumption that standardizing the work to serve the greater system of how the work needs to be done vs. allowing each person to do the work differently is difficult for people to embrace.

I have learned that it is only through actually standardizing the routine work elements by applying a common method of thinking, that enables true problem-solving and drives innovation. Along the journey to standardizing the work as a leader you are faced to grapple with preconceived notions and urban legends that likely have long caused struggle for your team.

Building a Lean Operating and Management System

Gain the in-depth understanding of lean principles, thinking, and practices.