Dear Gemba Coach,

You often say that one can’t do lean without kanban, and that continuous improvement without kanban is fine, but not lean. My team works on projects in an office, I fail to see how kanban applies. Are we barred from lean forever?

Face it: TPS is a technology. Technologies come with specific artifacts that make the whole thing work. Before lean (TPS outside of Toyota), there was TPS, before TPS, the system was called the kanban system. Before that it was called Ohno’s system. Kanban is absolutely core to understanding lean because most lean tools were built around kanban.

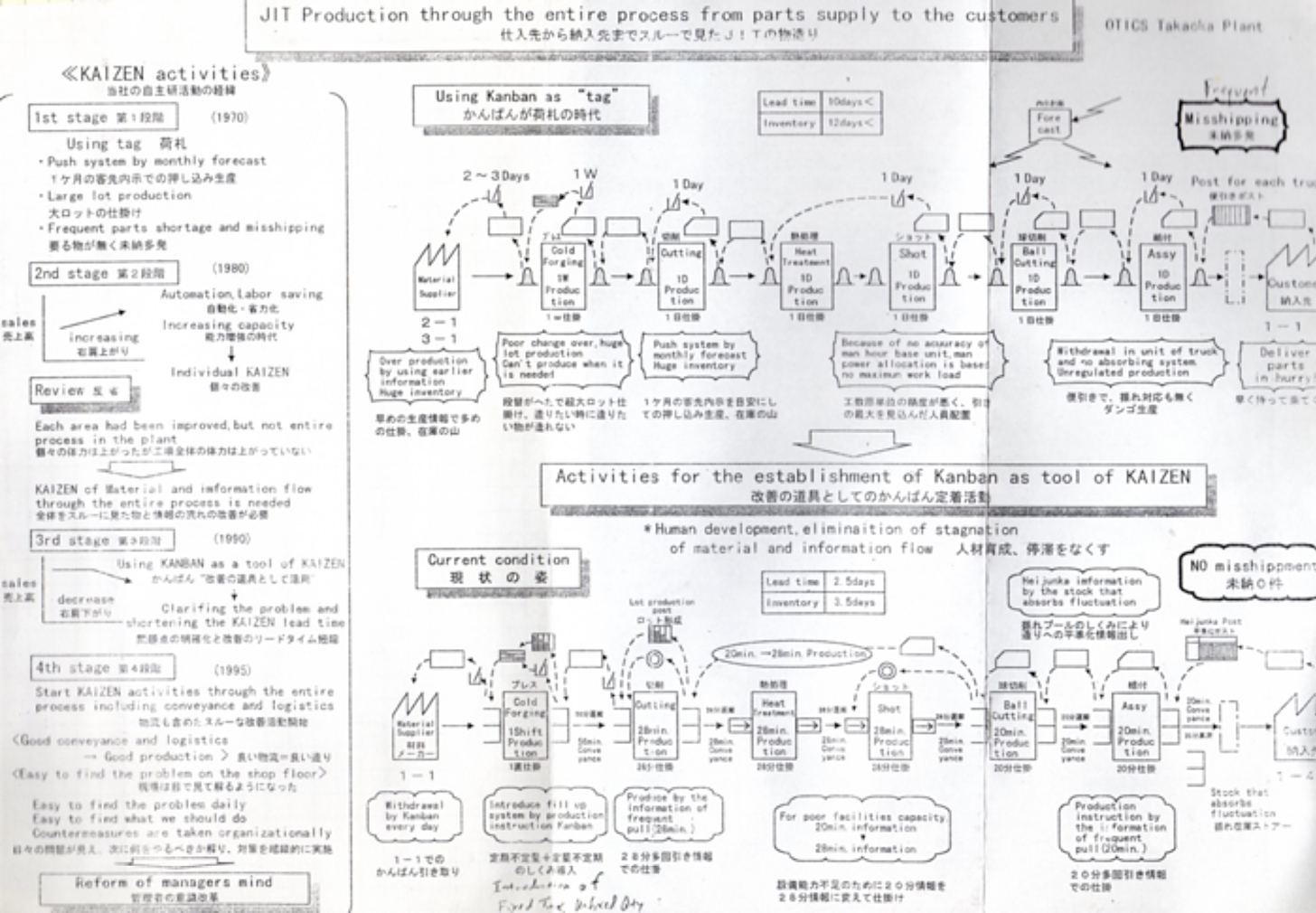

What does kanban do, as a lean artifact? The main thing to grasp is that kanban is a tool for kaizen, not the other way around (See the box in the center of the below graphic.) Kanban is not a clever system to replace workflow management. It’s a device to reveal problems and lead people to think more deeply about their work. Within Toyota, the aim of implementing kanban is the “reform of manager’s mind.”

How does that work out in your office? Think of the first efficiency in the self-organization playbook. Every evening, list the three most important things you’ve got to get done the next day. When you get to your desk in the morning start with the first, don’t go to the second until you’ve finished the first, then take on the second, and so on until you’ve done all three. Then do the rest of the day as it comes.

This is so powerful because we clutter our mental desk with all sorts of future work – things we have to do at a certain point in the future, and are afraid that we’ll forget if we don’t plan them firmly.

Doing so opens the door to procrastination. You take on a task. You hit an obstacle. You feel blocked, so you put it aside and take on another task. You hit another obstacle. So you move on to a third task. Pretty soon you’re back to your first one, nothing has progressed significantly, the morning is half gone and you’re weighed done with worry for all these things still not done.

When a new job comes into the office, the natural tendency is to attribute it immediately to someone. This needs doing, hey Alice why don’t you take it?

This creates a backlog of future work – or inventory if you like – on Alice’s desk. She’s overloaded, miserable, and prone to procrastination.

The kanban trick is to hold all new tasks on a central board, and only attribute them when one of the teams has freed their desk of what they’re currently doing:

Working like this has three major advantages:

- Each person takes on one task at a time (okay, on projects with some internal waiting time, you might want a small inventory of say, three tasks) and in doing so can focus more mindfully on each job and get it done effectively. The lower the inventory, the more diligently you have to deal with the obstacles blocking the way.

- As you select the next task you’ve got to think about it: Is this urgent; should we prioritize it? Why are we doing this in the first place? What is the benefit? To whom?

- This gets you to reflect on what matters and what doesn’t, what works and what doesn’t, and will improve your office’s collective productivity as the team progressively learns to spend their time on value-adding work.

This kanban system teaches you how to increase the value added of your team. The goal, to start with is that every person does at least one hour of 100% value added a day, which in much project work is already a high bar.

Note of caution – kanban is NOT what the IT guys call “kanban” in agile teams.

What they do is put the workflow on the board, which has the merit of visualizing it for the whole team and makes it possible to discuss obstacles as a team more easily. But it does nothing to clear the desk of overloaded team members or look into the value of each task. Managers like this because they can keep control of the process while having some team collaboration, but it completely misses the purpose of kanban, which is (1) following customer real demand, (2) lowering the inventory of parts on hand, and (3) accelerating the flow of production instruction.

To your question: Yes, I really believe you can’t do lean without kanban. You’re probably doing continuous improvement – and that can’t be bad – but it’s not lean as long as there is no systematic tool to challenge the value of what we do for customers and to improve the ease of work for people piece by piece.

After years of applying lean as tools without understanding their purpose (in kanban’s case, using cards to schedule production rather than spur kaizen), the current tendency in lean is to play around with “principles” without feeling the need to learn the tools – this is akin to having ideas about the digitalization of companies without coding. Learning is demanding. It requires clarity on (1) scoring of what you’re trying to learn and (2) the practical search strategy you’re adopting. With just-in-time, the score is on-time delivery with greater variety and smaller batches. The strategy is kanban and SMED. Claiming to adopt lean thinking without practicing kanban and SMED is easy, but won’t deliver much real learning – or sustainable performance improvement.