How would you, or should you, make your mark during your first 90 days in the role as a ‘lean leader’ in an organization?

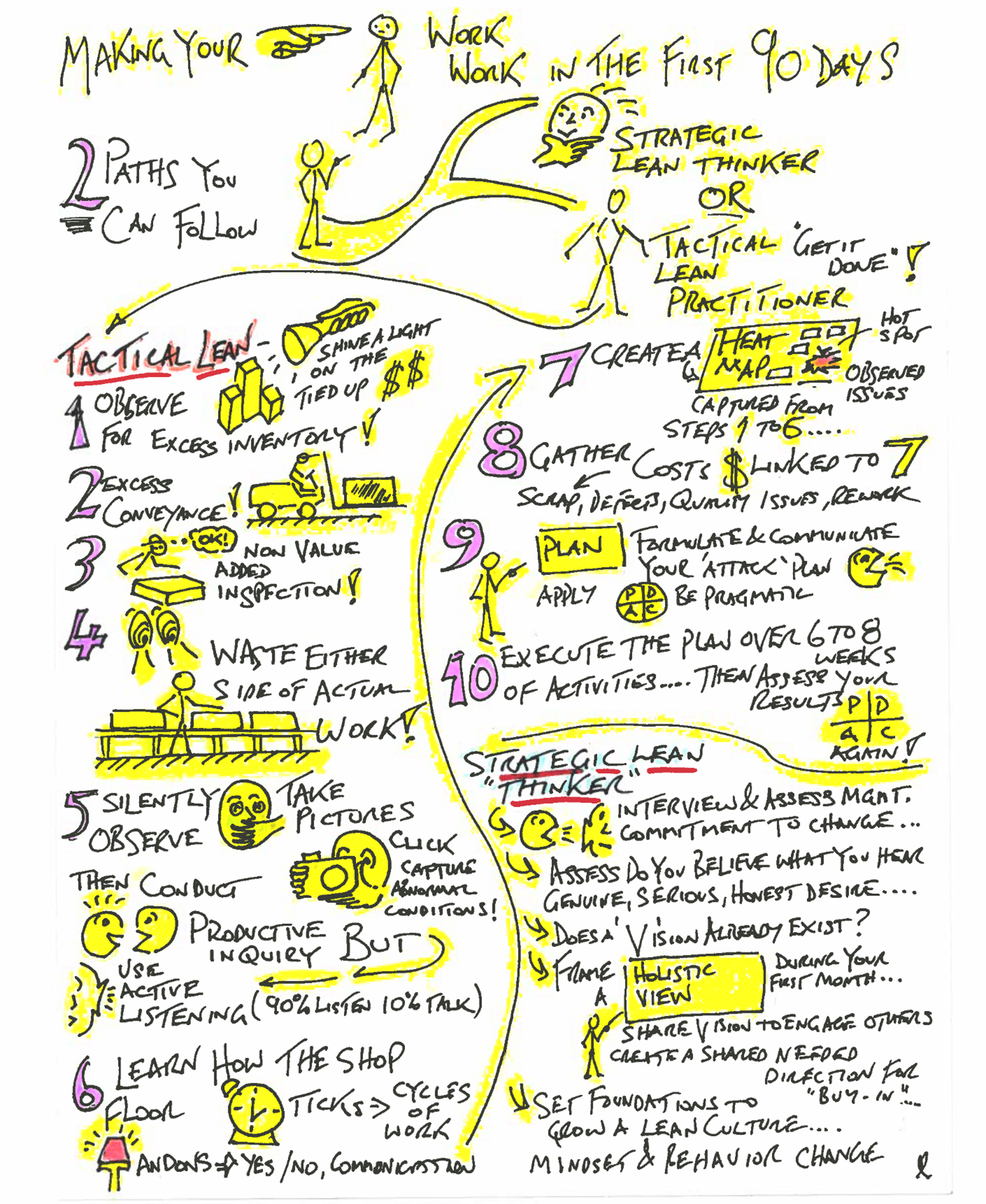

There are two paths you can consider: 1) were you brought in as the new lean ‘firefighter’ for the organization—a tactical “get it done” role? Or, 2) were you brought in to help build a ‘lean culture’ in this organization, as a strategic thinker to create the road map for a transformational change?

Let’s explore these two paths more closely. What could you do, for example, if you assume the ‘firefighter’ role? You might consider trying a number of these actions steps in your first 90 days:

- Observe operations on the floor, how much inventory is being held (cash tied up the business can’t spend), ask the why, why to understand if this inventory is necessary, or is it a comfort blanket, hiding a capacity or supply problem?

- How much conveyance is going on in the plant? What are we moving where, why, and what for? Spaghetti diagram the waste and lost time and ask: are we being inefficient?

- Where are we doing non-value-added inspections, and where do we have ‘quality walls’ (100% sorting verification) to catch issues? Use kaizen to eliminate this.

- Observe each step of each process at every and ask yourself: what waste can you see to the actual ‘value added’ work being done? Are processes running at standard baseline conditions and timing? Do workarounds exists, taking us away from the ideal originally established? Plan to kaizen them away!

- Observe everything (silently, using eyes or with pictures) across multiple days to see variations. Perform ‘productive inquiry’ by asking open ended questions, never interrupting, listening deeply to what you are told, and reciting back what you have heard to make sure you understood properly.

- Learn how the shop floor actually runs, which should reveal, how the people think and act (floor culture), how they can see waste (as you do), and accept that abnormal is probably normal to them in this environment.

- Create a ‘heat map’ of the problems and bottlenecks you have seen on steps 1 to 5, quantify these with collected data, using information from your interviews to support gathered data.

- Based on you produce this heat map, verify how this relates to known customer quality issues, and any scrap, defect or waste problems. Then use their metrics or KPI tracking to obtain the real costs of quality.

- Spend four to five weeks on steps one to eight, doing weekly one to one updates with your boss on your progress. Agree on a communication strategy on how to tackle your stakeholders in formulating your action plan (PDCA), highlighting the big ticket items and low hanging fruit you can see to be fixed.

- The next six to eight weeks should be all about execution and returning things to standard, removing and reducing inconsistency, strain and burden; and demonstrating you can contribute to the bottom line.

These items are all about ‘YOU’ establishing credibility and trust with the shop floor. You will have listened to your people and seen their issues, helped them properly fix things that were broken, and established your role in providing support. In so doing you have formed a foundation to build upon in the coming months and years. You will have demonstrated humble leadership, drawn from facts supported by data, sought incremental gains (as they will stack up fast); and taken every opportunity to connect with as many folks as possible during your early months to start growing a network and win over some supporters and disciples to the lean cause. You have followed through on the social aspect of change by helping improve specific situations while engaging others in an open manner. And as a result, you will have shifted from simply detecting opportunities to apply lean as a “fix” and moved on to prevention planning—in other words, considering and apply lean properly from the outset.

So, having now discussed the first path, let’s look at how the second path, that of the “cultural builder” contrasting with the ‘firefighter’ role? Your behavior as a change agent and transformational person would surely need to include a number of the following moves pointed out below:

- Interview the senior leadership team to assess their commitment to continuous improvement and what they see as the investment needed in people for the desired business change.

- Assess what you hear and feel: do you believe what they are saying? Gauge the desire for change.

- Is there a lean vision ‘true north’ already existing that the company is pursuing?

- Where can you see evidence of it living or being deployed and used? Did it stall? If so, why?

- Try to frame a holistic view during your first month before you dig deep into planning.

- Look for where you can see CI being applied in the daily work, on a daily basis:

- 5S on the floor and in the office areas.

- Autonomous maintenance/clean & checking on the shop floor.

- Do the lean tools exist to get things done by team members independent of support squads coming in necessarily?

- Is kaizen part of the routine or just an event?

The points above will help you map out if foundations from a culture mindset and behavior perspective already exist for you to build upon, and where there is a real appetite for positive change that the senior management team will support you to execute on.

In conclusion your first 12 weeks should be about framing your transformational plan of action, aligning the elements in the foundations and walls of your TPS style house, and then building the team to help you deliver, either from the existing talent pool or canvassing to bring in more ‘change agents’.

Again, understand how the business runs, and how your transformational approach will complement the strategic priorities of the business. Build a ‘hoshin plan’ covering the devil in the detail and create a story line to sell your approach to all levels within the business as you roll out across a one to three-year window to start. Make sense? I hope so.