With the current economic turmoil impacting companies of every size, organizations must begin to change how they conduct business and even reconsider what products and services they deliver. Business leaders will need to adjust not only what their companies make but also many other fundamental strategies like:

- Capital investment choices – what equipment, offices, plants, and general space they need

- Organizational structure

- Workforce capabilities

- The fundamental way that we all work together vertically and horizontally across the organization.

- The business vision and mission

Now more than ever, we need a mechanism, a management system that allows the organization to quickly and effectively adjust its priorities while engaging the team. As we all sit isolated, it is a time to make sure people feel respected and engaged in the business and to draw their insights forward.

My experience tells me that hoshin kanri can be that mechanism.

Remember 2008?

Those of us who were in the workforce in 2008 worried what would happen to the world when the financial system collapsed. Yes, 2020 seems like a bigger problem, for sure.

I worked at Toyota North America at the time, and we were ready. We had built stronger teamwork and alignment across our operations through several “cycles,” significantly strengthening our hoshin kanri process. Our improvement didn’t mean things went smoothly. Toyota experienced three significant challenges in quick succession: the Great Recession (2008), a quality crisis (2009), and the Sendai tsunami in Japan (2011) that fractured our supply chain.

Throughout those upheavals, Toyota North America doubled down on its strong system of hoshin kanri. When our 2009-10 hoshin focused on Quality and Safety, it sent a clear message to everyone in the company. Toyota worked to regain customers’ trust by increasing its focus on quality. To many, Toyota’s quality crisis seems like a distant memory because it recovered so quickly. Toyota also refocused on supporting its Team Members through the crises. We felt reassured that the company was committed to us because its hoshin emphasized Safety, everyone’s top objective — plus the company didn’t lay anyone off.

Additionally, the consistent use of the hoshin kanri system served Toyota sales well through those potentially devastating events. Toyota sales from 2009 to 2011, immediately after the recession and during the quality crisis and tsunami, dipped only slightly. By 2012, sales reached higher levels, according to research published by the Center for Automotive Research (CAR).

Toyota’s Earlier Challenge

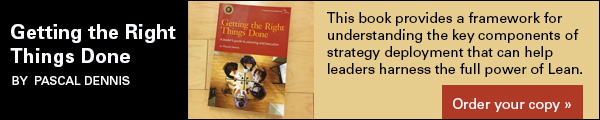

Toyota’s ability to pivot effectively in 2008-09 can be credited to its system-wide adoption of hoshin kanri across North American Manufacturing (NAM) operations starting in 2001. That year, Toyota North America’s challenges resulted from sudden growth that was not supported by an organizational structure that was aligned to a common set of goals. Let me share a bit about this story that I was fortunate to be a part of.

I spent 23 years (1988 to 2011) working in Toyota, both in Japan and the U.S. For seven of those years from 2001 to 2008, I worked at Toyota’s North American Operations Headquarters as the Assistant General Manager of Corporate Strategy. From about 1998 and through 2008, Toyota experienced unprecedented growth:

- doubling in less than 10 years its automotive production capacity from approximately 700K to 1.4 million with new plants in Indiana (1999), Canada (2003 and 2008), Texas (2006), and a joint venture with Subaru (2007)

- establishing plants to produce more than a million engines in North America: West Virginia (1998), Alabama (2003), and added capacity in Kentucky

- adding new capacity for engine blocks and transmission

This growth also required the addition of nearly 20,000 new associates who had to learn and work according to the Toyota Way.

Complex Decision-Making

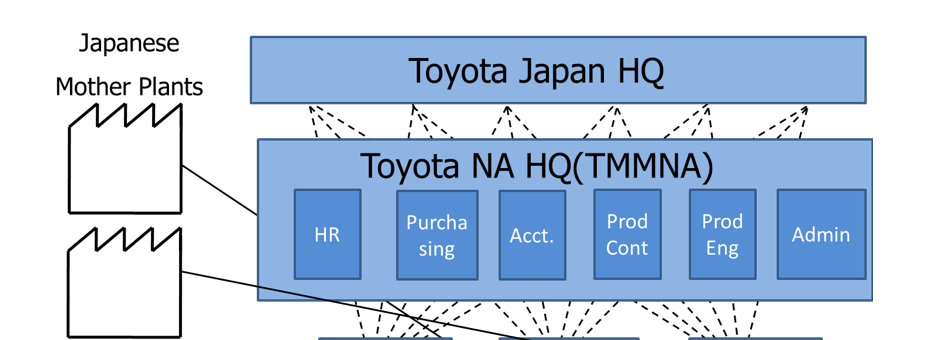

All this success came a bit of a price for Toyota. Toyota had established its North American manufacturing headquarters (Toyota Manufacturing North America or TMMNA) in 1996 to consolidate functions such as Purchasing and Production Engineering. However, it had kept its legacy decision-making structure — where plants reported to their mother plants in Japan. This setup robbed Toyota’s new headquarters of much of its decision-making authority and created an unnecessary sense of rivalry between and stifled teamwork among production plants in North America. Also, because North American leaders weren’t accustomed to being in charge, the plants didn’t look to leadership from TMMNA; they turned to their mother plants in Japan. Additionally, sometimes leaders in Japan did the wrong thing by stepping in and usurping authority from those in TMMNA, which resulted in duplicated effort and undue bureaucracy.

People often look at Toyota as this perfect company, but the situation I stepped into in 2001 when I entered Corporate Strategy was less than ideal.

Fortunately, I had some strong leaders around me like Mr. Niimi, who was CEO, and Mr. Miyauchi, who was head of Corporate Strategy. We all realized that what was truly needed was to fully embrace hoshin kanri as a tool to align our production leadership as a team and build our capability to adjust to this new reality of unprecedented growth.

Toyota is a company that believes innovation is born from need.Taiichi Ohno, the father of the Toyota Production System, says. “I strongly believe that ‘necessity is the mother of invention.’ Even today, improvements at Toyota are made based on need. The key to progress in production improvement, I feel, is letting the plant people feel the need.”

How Hoshin Kanri Helped Us “Feel the Need” for Change

Toyota didn’t invent hoshin kanri; it came out of the quality movement in the 1960s. In 2001, Toyota fully utilized hoshin kanri in Japan but was still learning how to use it in its overseas operations. Our challenge was to figure out how the system could help us transform our business quickly from one of a “subsidiary” function, reporting to our Japanese headquarters, into one of a self-reliant, team-oriented organization that operated more independently from Japan but as a single unit in North America.

The Hoshin Kanri Framework

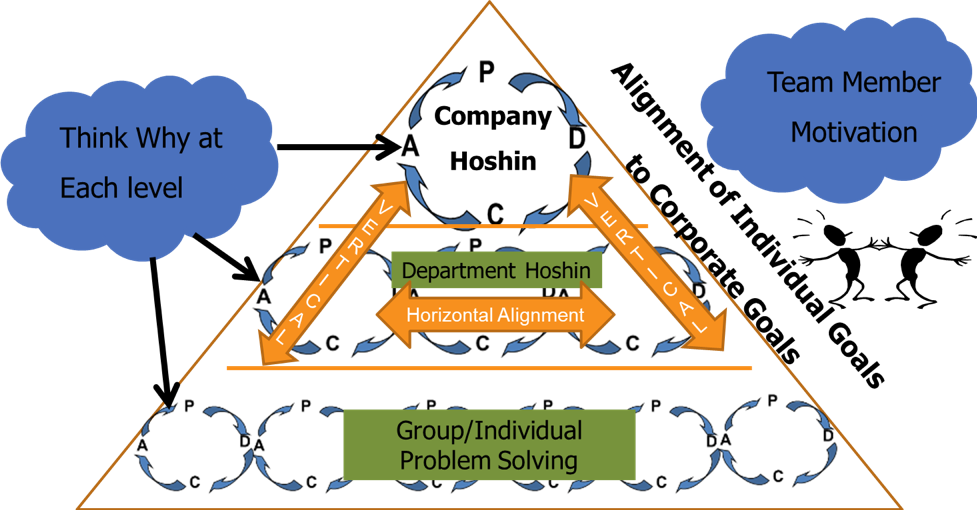

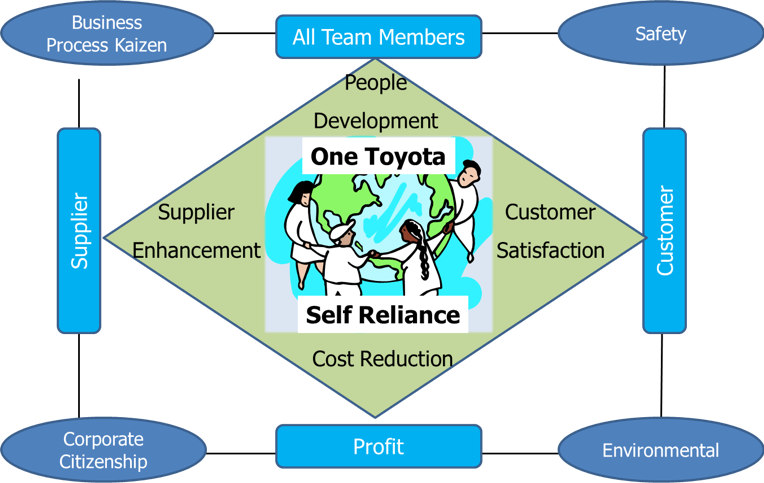

Hoshin kanri is a systemic approach for defining a strategy and, more importantly, a management system that engages all people to support that strategy while building horizontal and vertical alignment. This illustration represents the hoshin kanri framework similar to one we used at Toyota North America, showing our purpose to:

- Cascade hoshin objectives vertically in the organization, clarifying the “why” at each level.

- Build alignment both vertically and horizontally to our corporate objectives through problem breakdown and individual problem-solving.

- Achieve horizontal alignment to objectives across the company.

James Womack wrote an excellent Lean Post called The Cascade of Hoshin that speaks to this topic well.

As the first step in building alignment and teamwork, we brought together our North American executive team to establish a 2010 North American Manufacturing (NAM) vision based on Toyota’s global vision. It looked like this:

It looks like a car, doesn’t it?

We built four key initiatives in the core: Customer Satisfaction, Cost Reduction, Supplier Enhancement, and People Development—each of which had clearly defined executive leadership.

Finally, we built a rigorous management system that:

- Narrowed our core objectives to major items on our 2010 vision

- Defined each objective as a problem to solve – which helped us “clarify the need” as Mr. Ohno said

- Established cross-functional support teams that ensured both vertical and horizontal alignment to our objectives

- Created a clear PDCA structure to ensure progress was tracked and not impeded by siloed goals

- Focused on rigorous execution by breaking down the high-level objectives to specific, actionable countermeasures at the working level (shown in the hoshin framework)

Not What We Did But How We Did It

We accomplished all this in about six months, thanks to a new, self-reliant management system that created a PDCA structure within Toyota North American manufacturing. This new structure set the stage for several other critical changes we made over the next several years:

- We built teamwork across headquarter functions, between the headquarters and the plants, and among the plants. To do this, we assigned people to cross-functional teams. Most importantly, we built teamwork among our executives by doing the same for them.

- We developed the capability of our leaders to manage at a higher level because the system required that they think about problems one level above their authority. For example, a plant manager was assigned to lead Supplier Development for all of North America in collaboration with their TMMNA head of Purchasing at headquarters.

- We broke down problems to the working level and engaged all levels of the organization to solve them, as well as to innovate and think of their jobs differently. Success required strong alignment with corporate goals and purpose because we were big – about 30,000 people.

Not everything changed in six months. But the structure we put in place in the first six months and executed on from 2003 to 2007 helped us weather the upcoming storms.

How Can Hoshin Kanri Help You?

Depending on your location and industry, you are experiencing the Covid-19 pandemic in different ways. You may be busier than ever, or you may be figuring out how to help your business survive.

Based on my experience, hoshin kanri can help you greatly. So, what do you do?

- Bring together your team and talk about your core objectives. If you lead a big business, the process starts with the executive team; if small, maybe it’s the whole team.

- Define a few core objectives to focus on in the next six months. A year may be too long in the situation we are in now.

- Build vertical alignment both ways, to allow front-line people who do the work to contribute innovative ideas that help achieve corporate goals.

- Build horizontal alignment across functions — which likely will require abandoning traditional KPIs that measure people based on functional performance and assigning people to positions where they are uncomfortable and must learn new things.

- Finally, define a clear management system based on hoshin kanri — fixed and flexible, with clear standards for PDCA and the ability to adjust as needed. The hoshin kanri approach to strategy deployment creates the opportunity for your company to engage and motivate all levels of the organization to participate in new, innovative ways of thinking. Adopting the system also will help everyone feel more connected to the company’s purpose and colleagues during a critical time when we’re all feeling more isolated.

Managing on Purpose with Hoshin Kanri

Learn how to develop strategy and build alignment.