Big batches. Long lead times. Infrequent deliveries. Large inventories to cover fluctuations in demand. These aren’t characteristics normally attributed to lean paragon Toyota, but they once accurately described the automaker’s service parts distribution system.

Toyota’s Boston Parts Distribution Center at a Glance

- Opened in 1980

- 187,400 sq. ft.

- Two shifts

- 36 warehouse associates, 5 admin./support associates, 1 manager and 7 leaders (operations/logistics/customer service)

“We used to deliver one large stock order to our dealers every week,” recalled Bob Gallagher, manager of the Toyota parts distribution center in Mansfield, MA. In turn, Gallagher’s parts distribution center received a large weekly shipment of North American-made parts from a feeder warehouse in Kentucky and a large weekly shipment of Japanese-made parts from a feeder warehouse in California. Like any conventional distribution system with its low-frequency, large-lot replenishment cycles, this system baked in a lot of waste.

For instance, since dealers couldn’t accurately predict what parts customers would need the following week, they kept large inventories on hand to assure a consistent supply in between weekly deliveries. In turn, the automaker’s network of 11 parts distribution centers needed large inventories to supply dealers.

The system also hurt productivity at the parts centers as dealers would place daily “critical” parts orders — parts that had run out – in addition to their weekly stock orders. “Basically what we did in any warehouse in the country was go through once to pick the stock order then go through later in the day to pick the critical orders,” explained Gallagher. “We were making twice as many moves through the warehouse for each dealer.” Critical order volume climbed to as much as 45% of the daily order volume. The trick was to get the critical order volume down and the stock order volume up because the big productivity gains came from picking stock orders of standard replacement parts like spark plugs, filters, hoods, bumpers, etc.

The traditional system was inefficient for dealers, too. A big dealership in El Monte, CA, required two 48-foot trailers to deliver its weekly order. The dealer needed manpower and space to unload and stock the huge shipments. And the parts distribution center needed dock space equivalent to the two trailers to stage the shipment. This was space the distribution center could have used to speed up the unloading of parts arriving from the feeder facilities in California and Kentucky.

As Toyota sold more cars and models in the U.S., the problems would get worse — and more expensive — if dealers and distribution centers had to knock out walls and add staff to handle the burgeoning pile of new parts. It was money that could be better spent on marketing the new models or adding showroom space. Applying principles pioneered in its factories, such as one-piece flow, kaizen, and leveling, Toyota began a transition from conventional distribution to a just-in-time system.

One-piece Flow

Toyota built the new system on frequent ordering and delivering to replenish minimum stock levels covering actual demand. So, when a dealer in Vermont replaced the hood on a customer’s Camry, the dealer ordered one new hood from Gallagher, who delivered one new hood, not a pallet load, the next day. Gallagher ordered one new hood from the feeder warehouse in Kentucky, which delivered one new hood, not a pallet load, the next day, and passed the order back to the supplying factory. Toyota called it, sell one, buy one, make one.

Beginning in the mid-1990s, Toyota launched the new system on the west coast and gradually rolled it out nationwide. “A lot of training went on before it happened,” said

Gallagher. Eventually, dealers began placing daily orders with distribution centers. Parts ordered as late as 4:00 P.M. are delivered by 7 a.m. the next day. (Dealers can order critical parts as late as 6 p.m.) This allowed dealers to pare down inventory levels and only order on a critical basis what was absolutely necessary.

Mansfield used to stock many items, like the mats at the far

right, by the pallet load but now stores them in small lots

based on actual demand.

Gallagher explained. “A pretty astute dealer can tell what kind of inventory is needed for spark plugs, filters, and other maintenance items. An alternator for a 1978 Corolla is different. Any dealer needing one of those could order it today as a critical order and it would be in the shop by 7 a.m. tomorrow. But critical shipments are strictly for customers who have a vehicle down and the dealer doesn’t have a needed part.”“We basically took their once-a-week stock order and said, ‘We’ll give you a stock order everyday, so only order what you need to replenish your shelves,’”

Transportation Costs

With a 20-year background in traditional transportation, Gallagher said his first question about the new system was its affect on transportation costs. Usually, if an auto plant had ten cars going to a dealer, the company would negotiate the best rate for putting 10 cars on one trailer, he explained. Toyota’s philosophy was to determine if the dealer was getting 10 vehicles a week, then give it two every day. This “leveling” of the order resulted in lower total costs because it used less resources overall.

For instance, a dealer receiving 10 vehicles at once needed enough manpower to unload them and check them in, plus enough space to store them, etc. Those resources went unused on days when the dealer received fewer vehicles or none at all. But a dealer getting two vehicles daily needed less space and could make unloading and check-in part of someone’s regular routine. Eliminating the highs and lows created a more stable, predictable system with lower total costs.

Initially, some dealers were apprehensive about the new parts delivery system and hung on to unnecessarily large buffers. But others, convinced they could get what they needed the next day, quickly freed up hundreds of thousands of dollars in inventory that they devoted to advertising, building upgrades, or other improvements. “Over time we made believers out of all of them,” said Gallagher.

Most of the ordering now occurs automatically. Dealers set minimal stock buffer levels in their computer systems to cover historic daily demand. Say a dealer keeps two hoods in stock. When he sells one, the dealers’ internal system automatically orders one more from the regional parts distribution center. The system replenishes maintenance items, like spark plugs and brake pads, in quantities of 15 or less instead of full cases.

Orders go from dealers to Toyota Motor Sales headquarters in Torrance, CA, which checks key quality points such as having the correct part numbers so incorrect orders aren’t sent to distribution centers. Torrance also looks into the local distribution center’s parts database to make sure it has the needed parts. For the new system to work consistently, actual customer demand also had to be separated from demand created by sales. “If there’s going to be a promotion, sales will give us a heads-up and our procurement department will do some manual manipulation of the ordering system to make sure we have the parts.” Over a few weeks preceding the sale, inventory is increased.

Kaizen

To convert parts distribution centers to just-in-time distribution, Toyota trainers led jishuken (high-powered kaizen training) to improve key processes. Typical, was one that improved stock picking productivity while Gallagher was manager of the Chicago parts distribution center.

The main floor of the center held most parts but a mezzanine area held all the lower order frequency ones. “Every work assignment had at least one part in the mezzanine so associates would have to get the parts then come back down,” Gallagher explained. After making shop-floor observations and analyzing the work, the improvement team redesigned the process of picking parts to reduce the number of up-and-down trips.

Associates picked all the parts needed on the main level then one or two people, depending on the order volume, went up to the mezzanine to pick all the parts with low order frequency.

“So instead of 12 people going up there every hour, one person went up and sent down everything we needed,” Gallagher recalled. “It saved 11 people from having to go upstairs and downstairs.” The improvement saved several minutes every hour. That might not seem like much to managers in a conventional system “but you’re saving it on first shift and second shift,” Gallagher noted. “Then extend the savings out for a week. That’s really where you start to make your gains — a few seconds here a few seconds there, soon yours saving minutes then hours.”

Another change was grouping dealers served by the Chicago center into larger routes. Associates in distribution centers pick orders by routes, so creating larger groups meant fewer trips through the warehouse, saving time and further increasing productivity.

Ideas (kaizen) from various warehouses are shared through a web site. Each distribution center has an annual objective for kaizen projects. Once completed, the kaizen is defined in an A3 paper not to exceed 11” X 17”. Kaizens are then sent to headquarters which posts in on a web site accessible by any of the warehouses to examine. We pick up ideas from other warehouses, too.

Leveling

Probably the biggest benefit of the new system was leveling or smoothing the work in the parts distribution centers, Gallagher noted. In a conventional distribution center, managers typically give workers a list with eight hours worth of parts to pick from bins and shelves. “If you got it done in four hours, you figured out a place to hide for the other four hours,” said Gallagher. Based on a work analysis that included time studies, Mansfield implemented repeating 12-minute picking cycles to smooth the work flow and create a steady pace.

“We can use 12 or 15-minute cycles because both are divisible into 60 minutes,” explained Gallagher. There are advantages and disadvantages to each interval. Using a 15-minute cycle for picking parts means associates make one less trip per hour back to a wall-mounted scheduling box where they retrieve the next work assignments. However, they push bigger and heavier carts because they pick more parts in 15 minutes. “We figured out that 12 minutes was the best number for us here,” Gallagher said.

The scheduling (heijunka) box is a simple open-faced box with rows and columns of narrow cubbyholes, resembling an old-fashioned manual letter sorter. Despite its unassuming appearance, the impact of the box on maintaining work flow and pace is significant. Over the course of Mansfield’s two shifts, it levels or averages demand into a regular steady pace. Here’s how:

This heijunka box is loaded with kanban cards to schedule production,

but it’s similar to the one used at Mansfield for scheduling picking.

Each horizontal row of the box represents a truck route. (Mansfield serves 112 dealers divided into 18 routes.) Each vertical column represents a 12-minute interval. A computer and printer in the office adjacent to the schedule box print out order tickets resembling kanban cards four times daily at regular intervals. Each ticket is an order, such as one hood or in the case of common maintenance parts, a 10 piece box of spark plugs. An associate in the office groups the tickets into bundles of 32 for small or “bin” parts, 19 for larger items or “bulk parts,” and loads one bundle into each pigeon hole in the schedule box. (Observation and time studies showed associates could pick 32 small and 19 large parts in 12 minutes.)

“By having 12-minute cycles for both bin and bulk parts, each associate can pick five batches in an hour. That’s how we monitor productivity,” Gallagher explained.

Associates withdraw assignments in order from left to right. Using push carts, they withdraw the part and quantity from inventory noted on each ticket. To pick most items, associates use a cart with totes. Each tote corresponds to a dealer on the route being picked. Associates picking bulk parts use a larger cart. The warehouse also is laid out to optimize efficiency and safety. Heavy bulk parts are close to the shipping dock as are fast moving parts. In 12 minutes, they bring the carts with the fulfilled batch of orders to shipping lanes in front of the waiting trailer assigned to the route they are working on.

Then they withdraw another bundle of tickets.

A yellow card accompanying a bundle signals the associate that this is the last batch for the route. He or she has an extra 12-minute cycle to close the staged totes and load them into a wheeled cage that other associates will roll onto the trailer. The completed tickets are placed in a box on the cage. The first truck loaded is the one destined for Maine, the farthest route. Drivers have keys to dealerships so they can deliver parts to secure areas. A contract carrier delivers to the most remote points. An in-house trucking operation does the balance of the routes.

Leveling combined with historical data, gives Gallagher a very good idea what the “line count” or order volume from dealers will be on a given day. “We can predict with pretty close accuracy on a given Monday, which is our heaviest day of the week, we’re going to ship anywhere from 10,500 lines to 11,000 lines, said Gallagher. You can almost bet on it.” On a recent Monday, Mansfield shipped 10,984 orders.

This data used with home-grown software helps managers plan manpower needs. On a recent day, the software showed 9.25 associates were needed to pick the order for routes 1 through 4. Ten pickers were assigned initially, but one would be reassigned later to work other routes to account for the fraction. If managers know how many people are

needed to pick orders, other associates on the shift can be assigned to unloading the six trailers arriving daily from the two feeder warehouses, rather than everyone picking or everyone unloading, which works against the leveling standard.

Vertical storage saves space. Mansfield associates designed many of the vertical storage systems during kaizen workshops.

Manpower plans used to be disrupted when dealers were open on a holiday that the center observed. The following day, Mansfield would be “deluged” with orders from dealers, Gallagher explained. As a countermeasure Mansfield’s holiday schedule is synchronized with dealers’.

Small-lot high-frequency deliveries, combined with a careful analysis of actual demand, allowed Mansfield to free existing space to stock parts for new models. If sales data showed the distribution center sold one hood per week, two were stocked in the primary storage location at floor level and two held in safety stock on the rack above the primary location. When one is sold, another one is ordered from the Kentucky warehouse. With much smaller lots kept in inventory “we can use a storage area that was only for bumpers for six part numbers,” Gallagher explained.

Mansfield is gaining additional space by devoting kaizen events to improving how parts are stored. For instance, storing parts vertically takes up less room and causes less damage than storing them flat.

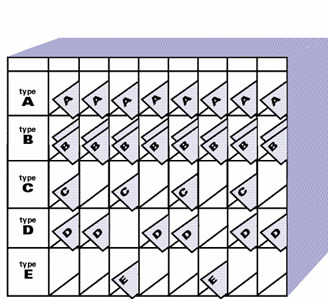

Toyota uses the following guidelines for storing parts:

- Group similar parts together (raw metal, small box, large box, exhaust systems, loose bin parts, hoods, doors, bumpers, etc.).

- Store parts vertically.

- Store within easy reach of associates.

- Store heavy parts where ergonomically safe.

- Separate locations for each part number.

- Right size storage locations to identify over supply.

- Store based on movement (fastest moving parts in front of warehouse).

If parts are moved from safety stock to the primary location, the fork lift driver records on a ticket the date and how many were moved. At end of the month, managers review the data to see if too many parts are being moved too often much. If there is too much movement of a part out of safety stock, they’ll make the primary location larger.

Toyota is saving space and money by using bubble wrap on large parts, such as these bumpers, instead of corrugated packaging. The wrap has a foam coating on the inside that prevents scuffing.

The goal is to never touch safety stock, Gallagher said. Having fork lifts replenishing storage locations from safety wastes time and hurts productivity. “If you have your calculations for primary locations correct, you never have to touch your safety stock.” The calculation is based on sales history and the replenishment time from the California and Kentucky warehouses. Safety stock serves as a buffer in case a delivery truck breaks down or bad weather causes a spike in accidents and the resulting repairs at dealerships. “We keep an eye on safety stock and try to pare it down over time,” Gallagher said. Safety stock is not rotated except for batteries and few other dated items.

Small lots and minimal safety stock has done “wonders,” said Gallagher. “It does several things. It’s going to allow us to remain in this building longer because it gives us more room by condensing the amount of space you need for a given part number and when you have less inventory in a building you have better visual control of the inventory on hand. Plus, it’s allowed us to take a lot of inventory out of the supply chain.”

Vital to maintaining minimal storage locations is unloading within 24 hours the six trailers carrying replenishment parts that arrive daily from California and Kentucky. Mansfield used to delay unloading if Monday was a very busy day for picking orders received during the weekend. But that often resulted in working on Saturday and some freight being five days old. Now, associates will work one or two hours overtime if necessary to unload all trailers on the day they arrive. “Before we go home all the trailers we got that day are put away,” Gallagher said.

Next Steps

Arriving parts bear labels indicating the part’s location in the center. An associate scans tickets arriving with the parts to update the computer record of what’s in stock. “It’s kind of an antiquated way to do it but its real simple and it works,” said Gallagher.

A new tracking system in development will replace the paper tickets with radio frequency identification tags that will update inventory records when freight arrives on the receiving dock. The system will equip receiving carts with receivers and small computer screens

that will show associates the best sequence for putting away parts that just arrived. The changes reduce “binning days,” a key measure of how long it takes to unload freight and move Mansfield another step toward the “ultimate goal” described by Gallagher as “satisfying the customer and shrinking the supply chain by taking out inventory.”

| Boston Parts Distribution Center Box Score | ||

| Productivity | +3% annually | |

| Inbound Binning days (time to unload truck and stock parts ) | ||

| Inventory (days of supply) | 32.2 days | |

| Picking Errors per thousand orders | .64 errors for every 1000 lines picked | |

| 1981 | 2006 | |

| Ratio of critical orders/stock orders | 45%/55% | 5%/95% |

| Toyota models sold in U.S. | 7 | 17 |

| Warehouse size | 187,400 sq. ft. | 187,400 sq. ft. |

Lean Warehousing and Distribution Operations

Improve a distribution center's efficiency, quality, safety, and space utilization.

thank you for this valuable information.