5S

5S refers to five related terms, beginning with an S sound, describing workplace practices conducive to visual control and lean production. The five terms in Japanese are:

- Seiri: Separate needed from unneeded items—tools, parts materials, paperwork—and discard the unneeded.

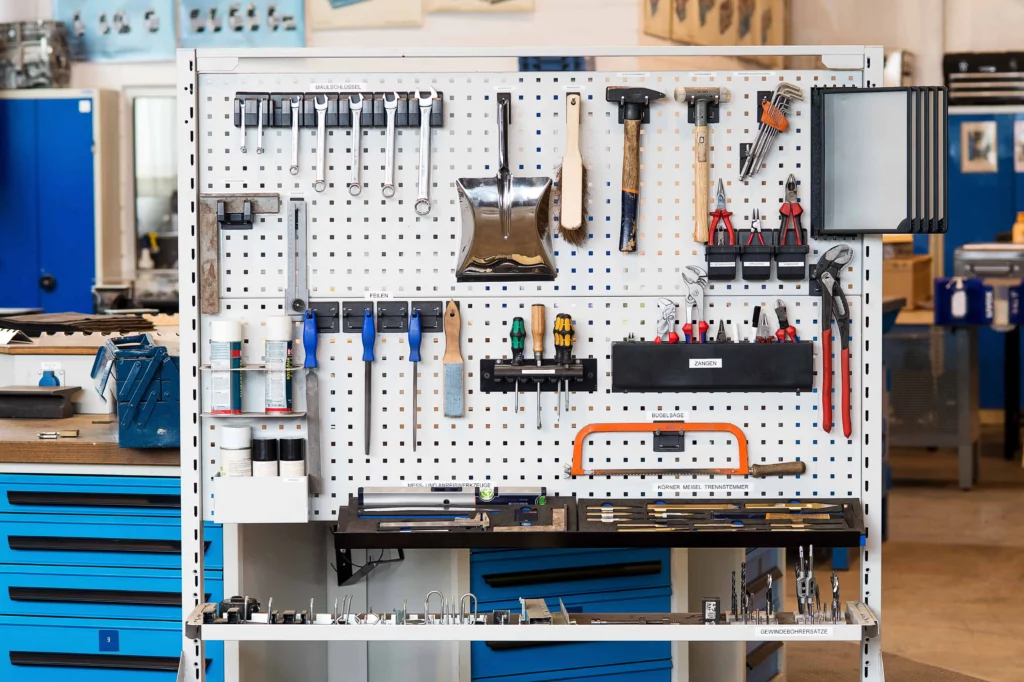

- Seiton: Neatly arrange what is left—a place for everything and everything in its place.

- Seiso: Clean and wash.

- Seiketsu: Cleanliness resulting from regular performance of the first three Ss.

- Shitsuke: Discipline, to perform the first four Ss.

The Five Ss often are translated into English as Sort, Straighten, Shine, Standardize, and Sustain. Some lean practitioners add a sixth S for Safety: Establish and practice safety procedures in the workshop and office.

However, Toyota traditionally refers to just Four Ss:

- Sifting (Seiri): Go through everything in the work area, separating and eliminating what isn’t needed.

- Sorting (Seiton): Arrange items that are needed in a neat and easy-to-use manner.

- Sweeping Clean (Seiso): Clean up the work area, equipment, and tools.

- Spic and Span (Seiketsu): The overall cleanliness and order that result from disciplined practice of the first three Ss.

The last S—shitsuke (sustain)—is dropped because it becomes redundant under Toyota’s system of daily, weekly, and monthly audits to check standardized work. Whether four, five, or six Ss are used, the key point to remember is that the effort is systematic and organic to lean production, not a “bolt-on” stand-alone program.

What Is the Purpose of 5S?

The true purpose of 5S goes deeper than a one-time housecleaning. The 5S methodology is a way to: create standards that reveal problems, support the basic stability needed to sustain incremental gains, reduce waste in all forms, build a disciplined workplace where teams focus on value-creating work, and nurture the essential sense of shared purpose needed to continuous improve to take root. An elegant way of describing this can be found in Gwendolyn Galsworth’s Visual Workplace, Visual Thinking: “The 5S system is designed to create a visual workplace, that is, a work environment that is self-explaining, self-ordering, and self-improving.”

Beware: Many stress the hazards of misguided 5S “programs” that merely add bureaucratic rules that prevent new learning and disable true initiative. “5S really is a method to teach people to take ownership of their own work environment so that they can perfect their standardized work by placing things at their most convenient place. Instead, in most companies I visit, 5S has become a bureaucratic program to make the workplace look neat, with no consideration for waste all over, and a fixation on “discipline.’” Ballé adds in How Can I Keep Our Lean Management Effort From Becoming Bureaucratic.

Top 5 Articles

- Lean Roundup: 5S

- 5S for Information

- 5S Again and Again and Again

- Jim Womack Provides Us with a Few Tips on How to Sustain 5S

- How do I implement 5S when operators think everyone does things a little differently?

Additional Resources