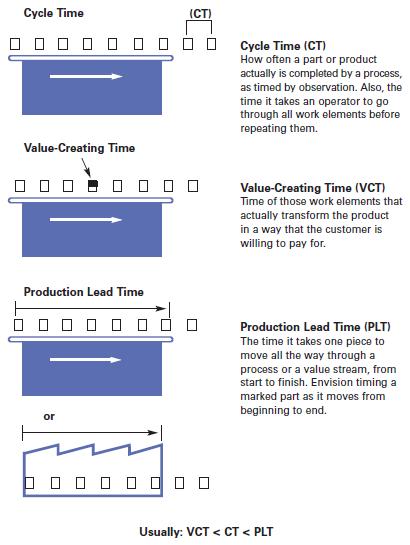

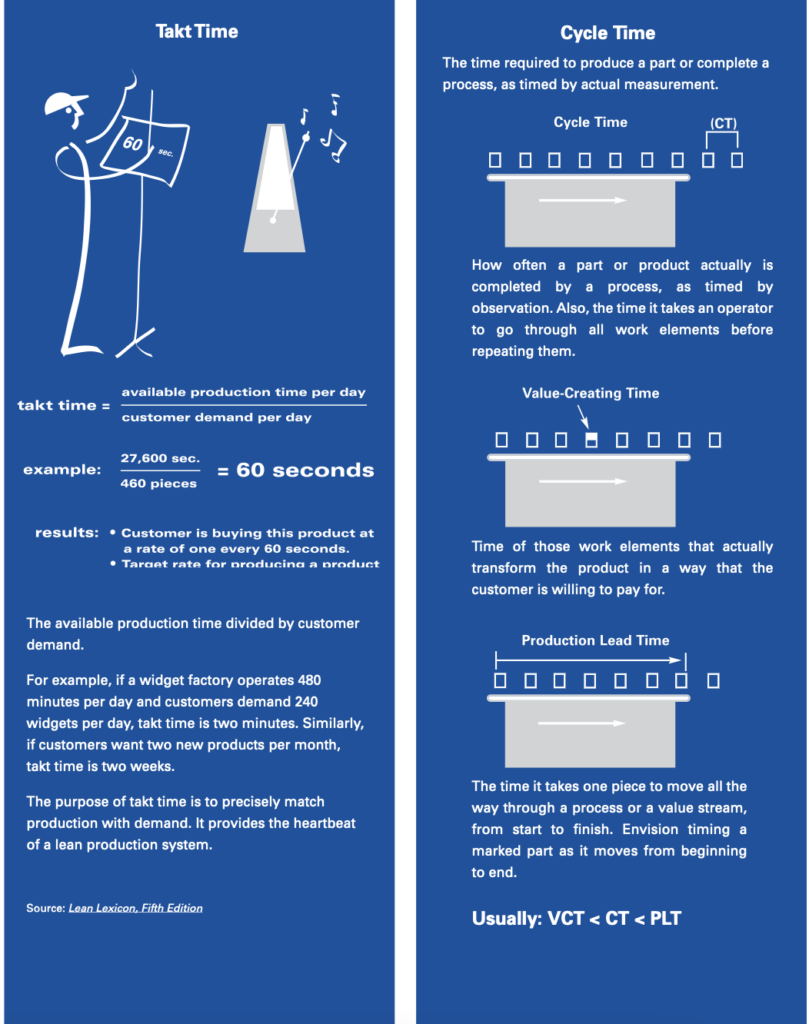

Cycle Time

Cycle time is the time required to produce a part or complete a process, as timed by actual measurement.

Cycle Time-Related Terms Involving Time

Effective Machine Cycle Time

Machine cycle time plus load and unload time, plus the result of dividing changeover time by the number of pieces between changeovers. For example, if a machine has a cycle time of 20 seconds, plus a combined load and unload time of 30 seconds, and a changeover time of 30 seconds divided by a minimum batch size of 30, the Effective Machine Cycle Time is 20+30+(30/30) or 1 = 51 seconds.

Machine Cycle Time

The time a machine requires to complete all of its operations on one piece.

Nonvalue-Creating Time

The time spent on activities that add costs but no value to an item from the customer’s perspective. Such activities typically include storage, inspection, and rework.

Operator Cycle Time

The time it takes an operator to complete all the work elements at a station before repeating them, as timed by direct observation.

Order Lead Time

Production lead time plus time expended downstream in getting the product to the customer, including delays for processing orders and entering them into production and delays when customer orders exceed production capacity. In other words, the time the customer must wait for the product.

Order-to-Cash Time

The amount of time that elapses from the receipt of a customer order until the producer receives cash payment from the customer. This can be more or less than order lead time, depending on whether a producer is in a build-to-order or a ship-from-stock mode, on terms of payment, etc.

Processing Time

The time a product actually is being worked on in design or production and the time an order actually is being processed. Typically, processing time is a small fraction of production lead time.

Production Lead Time also Throughput Time and Total Product Cycle Time

The time required for a product to move all the way through a process or a value stream from start to finish. At the plant level this often is termed door-to-door time. The concept also can be applied to the time required for a design to progress from start to finish in product development or for a product to proceed from raw materials all the way to the customer.

Value-Creating Time

The time of those work elements that actually transform the product in a way that the customer is willing to pay for. Usually, value-creating time is less than cycle time, which is less than production lead time.