First In, First Out (FIFO)

First In, First Out (FIFO) is the principle and practice of maintaining precise production and conveyance sequence by ensuring that the first part to enter a process or storage location is also the first part to exit. (This ensures that stored parts do not become obsolete and that quality problems are not buried in inventory.) It is is a necessary condition for pull system implementation.

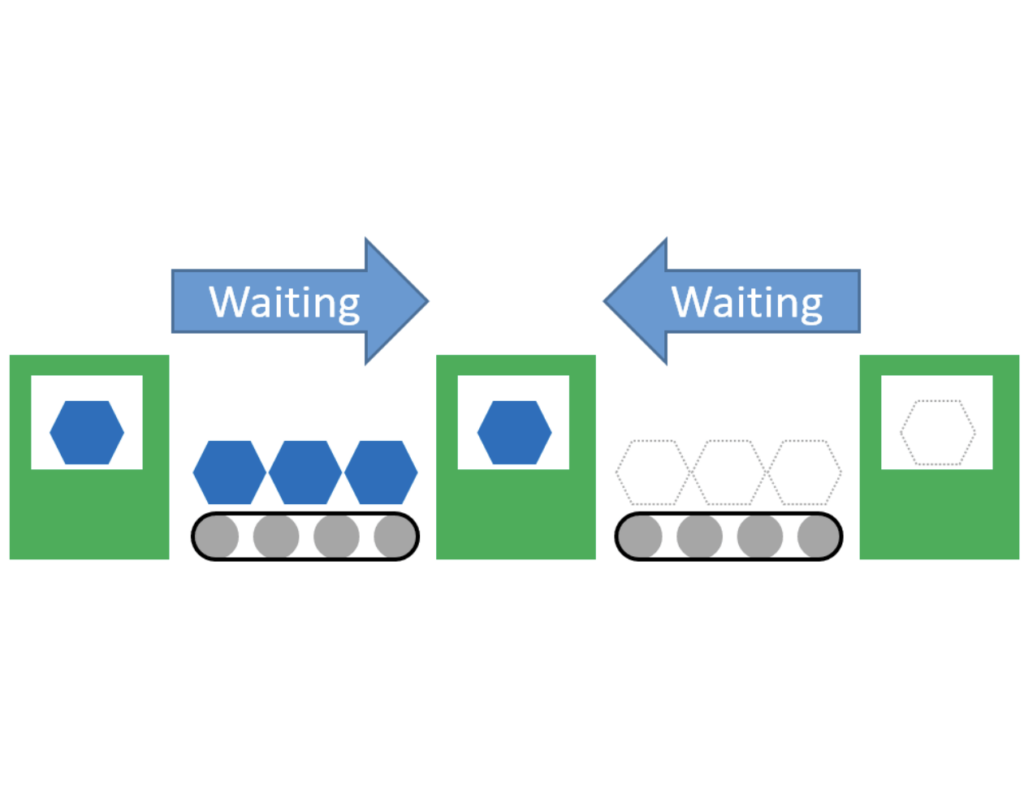

The FIFO sequence often is maintained by a painted lane or physical channel that holds a certain amount of inventory. The supplying process fills the lane from the upstream end while the customer process withdraws from the downstream end. If the lane fills up, the supplying process must stop producing until the customer consumes some of the inventory. This way the FIFO lane can prevent the supplying process from overproducing even though the supplying process is not linked to the consuming process by continuous flow or a supermarket.

FIFO is one way to regulate a pull system between two decoupled processes when it is not practical to maintain an inventory of all possible part variations in a supermarket because the parts are one-of-a-kind, have short shelf lives, or are very expensive but required infrequently. In this application, the removal of the one part in a FIFO lane by the consuming process automatically triggers the production of one additional part by the supplying process.

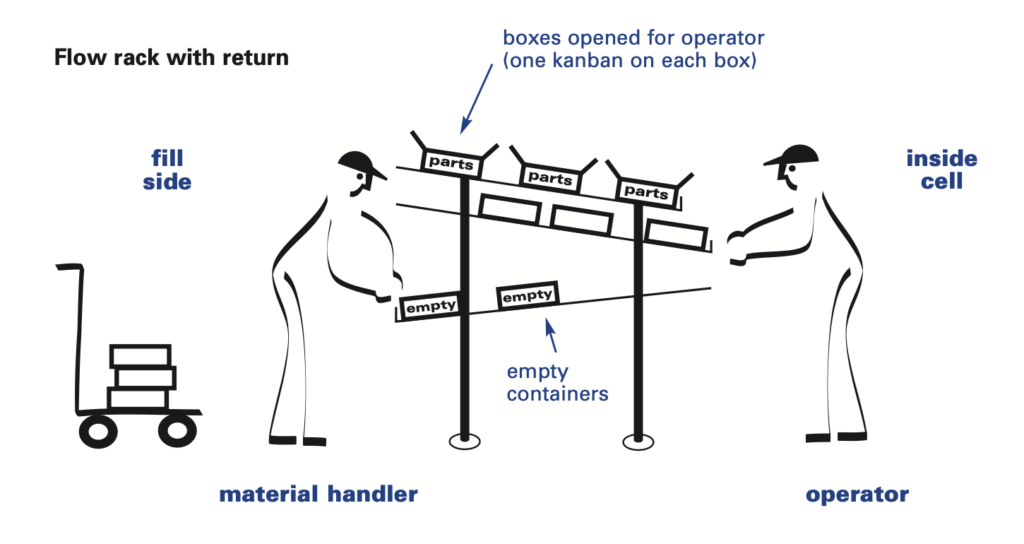

The image above demonstrates how to maintain FIFO in an assembly cell. A material handler loads the flow rack from the rear. This ensures the operator will use parts in the sequence the material handler replenished them. The flow rack is also sloped toward the operator. Consequently, the parts conveniently slide toward the operator as he places empty containers onto the bottom rack to signal replenishment.

Additional Resources on FIFO