Recently I spent a week at a prominent organization in the Midwest embroiled in an intense discussion about strategy with 45 of their supply chain group’s executives.

The topic was hoshin, commonly known as “strategy alignment.” Our focus was how these executives can work together to strengthen alignment across the organization. Everyone agreed that they currently do not have alignment to corporate goals within their function or across functions (like HR or Product Development).

How did this misalignment happen? In this particular organization, like so many, executives are measured against their department or function’s own unique goals. This results in conflicting priorities. Conflicting priorities stifle the whole organization’s drive to create value for the customer.

But, what a satisfying week for all. Why do I say this?

1. Everyone involved (all the way up to the CEO) acknowledged there was problem and was willing to speak openly about solving it.

2. We all spent one morning deeply analyzing the current process for strategic planning and thinking about ways to improve the process.

3. The group agreed that they need to start by aligning supply chain processes first (starting with self-reflection) before fully engaging other groups like HR or Product Development.

How did they come to this conclusion?

I’ve been working with this company for a while now. It’s taken a couple years of focused effort to develop a culture of lean thinking on the shopfloor where people can bring issues to light, openly discuss problems and work with their team members to tackle them. As we’ve piloted and implemented Standardized Work and Problem Solving, the problems have begun to come to the surface.

For example, operators struggled to assemble the outer case of the product due to fitting issues caused by the original design. The company came to realize that the work of all (management, engineering, HR) must focus on how to make the process better for the operator. You make life better for the operator by actively engaging the operator in improving his/her work and in so doing, giving him/her a chance to improve the work of the organization.

How do you build a continuous improvement culture?

First, you need some level of top management engagement and drive. In this case, the CEO recognized the issues of organizational alignment and felt the urgent competitive business need to make operations better through continuous improvement.

Next, work with your team members to think about what goals, objectives, problem solving opportunities the organization needs to align around. Aligning to what problems? You find out what problems to solve by going to the gemba. The work on the shop floor brings to light the problems that are getting in the way of the real value-added work.

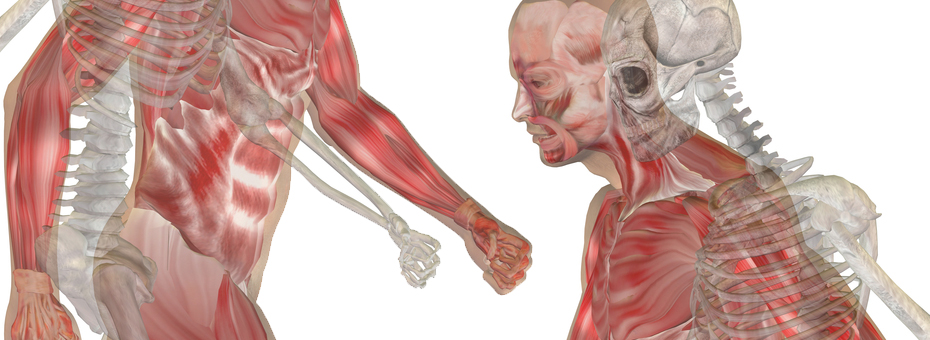

Think of hoshin (strategy alignment) like the human body. The body needs both a strong skeletal structure (hoshin) to hold it together (just like an organization). But a body can’t move effectively if its muscles (continuous improvement) are not kept active and developed.

A body where muscles are left to atrophy is weak, not adaptive and competitive. However muscles need something to connect to, something that connects them to each other. Individual muscles are to be aligned to a skeleton that provides a common purpose and way of thinking. In this way, continuous improvement and hoshin complement each other if practiced correctly. Continuous improvement strengthens the body; hoshin holds it together.

What happened with the organization I visited in the Midwest? They saw a huge benefit to “exposing” their misalignment. As a next step, we’ll organize similar events and discussions in other functions to create a common awareness horizontally across the organization.

Managing on Purpose with Hoshin Kanri

Learn how to develop strategy and build alignment.