Parker Hannifin Corporation, Climate & Industrial Controls Group, Climate Systems Division, New Haven, IN

When Aeroquip-Vickers Inc. built its New Haven, IN, air conditioning components plant in 1991; it mixed elements of lean management and thinking into the mortar and machinery. It was a time when many U.S. companies began learning about the Toyota Production System, and Aeroquip-Vickers had started on its lean journey the prior year.

Aspects of lean and continuous improvement continued to be part of the plant’s culture during the following decade, surviving two acquisitions and multiple reorganizations. In 1997, IndustryWeek magazine named the plant one of the 10 best in North America based on five years of tremendous quality increases, lead time reduction, better customer service, and profit improvement. Today, the plant is part of Parker Hannifin’s $985.1 million Climate & Industrial Controls group and is six years into a reconfiguration that is it’s most radical, yet most promising.

In January of 2002, the plant, known as the Climate Systems Division (CLS), created the first of what eventually would become five value-stream organizations where the staffing within the plant was organized around product families. While many plants have introduced value-stream thinking and practices such as current- and future-state mapping, the CLS plant has created a value-stream culture centered on autonomy, entrepreneurialism, and lean continuous improvement.

The change started after months of lengthy discussions and much soul-searching among functional leaders, who ultimately determined the best way to remain competitive was to relinquish much of their control to value-stream teams led by hand-picked managers.

“My vision was for the value stream to be a business. Period,” said Bradley D. Lichtenberger, operations manager. “Picking the value-stream leaders became critical because I wanted entrepreneurs. I wanted them to understand and believe that they control the business. They control the outcome of what occurs.” Melissa Darrigan, former divisional lean manager and now a unit leader overseeing several value streams, said the reorganization further focused lean-improvement efforts and has strengthened the connection between operations activity and customer demand.

“It gives them [customers] a touch point,” said Darrigan, who started her career at Parker as a product engineer. “When they call into the value stream, they have access to operations right away. That helps you be a lot more responsive. It also increases your credibility with the customer because when you say ‘I’m going to build these parts today and overnight them,’ or ‘I’m going to send someone to help you fix this problem,’ you are right there doing it. You are not passing along someone else’s information.”

Ups and Downs on the Journey

Having a lean culture requires flexibility and creativity as conditions change. Demand in the spring could be more than double demand in the fall. As the plant had decreased lead time over the years, it was able to respond to demand instead of building to inventory. This created the need to flex the workforce to cover a seven-days-a-week schedule in the busy season.

Additionally, product mix had grown more complicated. Growth was coming from supplying assemblies on a just-in-time basis rather than supplying components by the weekly truckload. The plant also had assigned on-site engineers to some key customers, a move that led to the development of new products and new orders. These changes significantly increased the part numbers being managed and reduced order sizes. The combination of business growth and seasonality made work life increasingly hectic and led to daily firefighting. The plant’s situation was exacerbated by a conviction to holding very little inventory. Actually, good lean practice is to determine the inventory for a process and to continually reduce it when possible but only after reducing downstream variations in demand and increasing upstream process capability and stability.

In 2000, an attempt to level demand, increase stability, and reduce dependence on excessive overtime began. The team also felt that it needed a better connection to customers across the manufacturing side of the business.

Key actions to accomplish these goals were:

- Reaching long-term order agreements with key customers, which allowed leveling of demand to manufacturing.

- Building an inventory buffer in the off-season for use during the busy season, which then reduced the need for overtime and contract workers.

- Reorganizing into value streams to shorten and improve the connection between production and the customer.

“As we looked at the business, we were — and fortunately still are — very good at firefighting. But we had really started to lose contact with the customer,” Lichtenberger said. “We had customer service, but needed better operational, engineering, and manufacturing contact.

“We realized when we were smaller — about half of the size we are today — we could work closely with customers. But as we grew, there was less and less time. We knew we had to get back to that.” Lichtenberger knew the change needed to come from people rather than product or technology. He and his management team began a discussion about how to restructure the organization. He asked his team of functional leaders:

- How would you run the system without silos?

- What would you do with your people?

“I knew they have got to be the ones who want to get rid of the silos,” Lichtenberger said. “I can want it to happen. Melissa can want it to happen to drive lean through. But if we don’t have individuals willing to give up some of their structure, it will never happen. So I spent a lot of time talking to people.”

Lichtenberger held one-on-one talks with members of his management team for six months, answering questions they had about what their roles would be in a value-stream environment, how much authority they would have, how it would be better for employees and customers, etc. He met with managers in Engineering, Procurement, Quality, Manufacturing, Maintenance, and the lean functions.

He met much resistance around the idea of physical location. Employees that provided support services, such as Engineering, Quality, and Purchasing, would no longer be sitting together. They would be assigned to a value stream and be sitting alongside their value-stream team members. Lichtenberger said he encouraged them to just give it a try. (One exception to functional integration is customer service, which is organized by customer, not value stream.) “Everybody was willing to try one area, but not change the whole plant,” Lichtenberger said. So, his leadership team picked the valve operation as the first value stream.

The move was so successful; there was no resistance six months later when Lichtenberger’s team started to reorganize the rest of the plant. “After six months, I had other areas coming up saying, „When are you going to put us in a value stream?’ There became a lot more excitement. People really became involved and enthused. It was their area to take care of, and they saw the results of their labor at the end of the day. They saw success, and they started pushing. Success began to break down the walls and then that broke down the fears.”

Building Culture and Sustaining Momentum

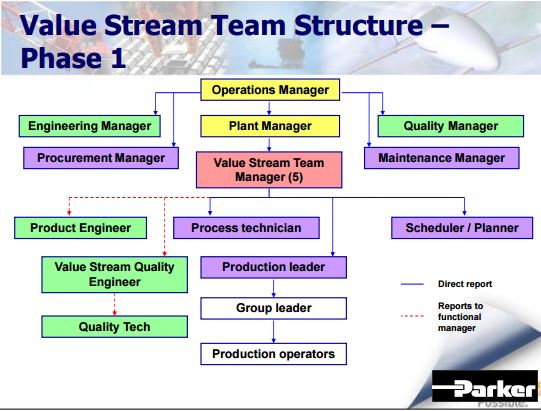

Today, one manager leads each value stream, which consists of production employees and support staff members. Functional leaders act in a leadership and support role by regularly meeting with their employees to review key metrics and discuss challenges and ongoing improvement efforts.

Annual goal setting begins at the corporate level and is cascaded down to the plant, value streams, and individuals through strategy deployment. This process begins with an annual off-site meeting where value-stream managers identify goals that support corporate strategy, which is based on the principles and measures of safety, quality, cost, and delivery.

- Value-stream managers plan projects to meet high level goals such as double-digit productivity improvements while reducing costs.

- Additional, supplemental projects, which can either make up for an unexpected shortfall on a high-level goal or push performance beyond that goal. (Examples of supplemental projects might be increased automation of one or more tasks.)

- Value-stream managers then create personal performance plans with team members based on value-stream goals and projects. Functional leaders offer input and guidance on the plans and performance reviews.

A series of meetings provide the plan, do, check, act cycles needed to keep track of projects and performance; allow for planning and adjustments throughout the year; and keep the functional leadership team connected to the value streams:

- Value streams meet weekly in war rooms, using strategy-deployment X-charts as a top-level matrix to track projects, tasks, responsibility and performance, as well as trend and Pareto charts.

- Every-other week, functional leaders attend the war-room meetings and hear reports on projects and specific metrics such as supplier quality and on-time delivery. If a metric is falling or a project faltering, the value-stream manager is responsible for researching the issue and coming up with a resolution. The

- functional leaders are there to support those efforts, freeing up resources, offering guidance and, if need be, lending a helping hand.

- Each value stream uses value-stream maps to identify the performance gap on high-level and supplemental projects. The future-state maps offer a longer-term look but change during the year depending upon adjustments made in plans to meet goals.

- Functional leaders plan regular meetings with their groups, such as Engineering, based on whatever frequency they feel is needed. Another large part of their job is going to the floor at least once a day to check the many planning and progress charts each value stream uses.

Lichtenberger stresses that these built-in checks and standardized analysis are the foundation of the value-stream culture. “Our strategy deployment process provides us our baseline,” Lichtenberger said. “If we didn’t meet every two weeks, those numbers would start to go down. It’s the nature of the beast. You’ve got to create the behavior. You’ve got to get your baseline down, then you get the behavior down, then you get your culture down, then you can sustain.” In terms of daily work planning, each morning Lichtenberger holds a five-minute meeting with functional leaders and value-stream managers for a broad-brush report of the upcoming day. Not discussed at this meeting is production planning, which occurs at the value-stream level and is driven directly by customer orders triggering material flow and activity on the floor. The plant generally turns orders around in a day.

One key to success for a value stream-based organization, according to Lichtenberger and Darrigan, is picking leaders with the right attributes — namely, being team oriented, willing to let others try and fail, and possessing a desire to see those around them succeed. This applies to both value-stream managers and functional-group leaders.

Value-Stream Team Leader

Has broad responsibility and leadership for overall operation of a value stream. Implements the Parker Lean system and strategy to ensure a safe work environment, maximize profitable growth, drive quality improvements, provide premier customer service, develop a technically qualified work force, reduce operating costs, inventories and lead times through continuous improvements. Oversee day-to-day activities to meet daily, monthly, quarterly and yearly expectations.

For instance, recently the plant hired a new quality engineer. While a silo-structured plant might have hired primarily on technical qualities, Lichtenberger looked for the ability to be a champion of the value-stream culture. “From a team standpoint, the new engineer fit in, because he knew how to be a good team player.” When it came to picking value-stream managers, Lichtenberger’s team of functional leaders wrote a job description and nominated current employees they felt were either up to the task or could be brought up to the task through training. They placed names on a white board and then debated prosand cons of each individual. Then everybody had a vote. It had to be this way, Lichtenberger said, to solidify support from each functional leader and group.

Business Unit Manager

Has responsibility for leading the business unit of a division and meeting objectives as identified by the corporation’s strategy. This position manages the profit and loss asset performance of the unit. Develop world-class manufacturing operations through the use of automation, documented processes, demand flow technologies, and a team of empowered employees to continuously meet customer expectations. Maintains close contact with customers to gain insight into their needs as well as general market requirements for unit products.

“The ability to put value-stream teams in had nothing to do with an individual. It had to do with a team trying to get a plant to succeed,” he said. “We all had a stake in this.

Third Stage: Growing the Business

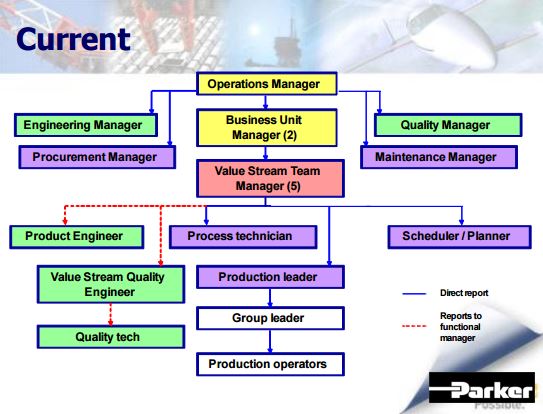

Despite the success of the value-stream reorganization, Lichtenberger describes his plant as at the beginning of the improvement journey. This is evident in the most recent reorganization of the value streams, which introduces the concept of revenue growth to the teams. “With the value-stream leader job, we did a very good job of maintaining our current business,” Lichtenberger said. “What I didn’t have was a way to go after new opportunities.”

About four months ago, Lichtenberger named two Business Unit Managers, who will oversee several value streams with product synergies that have the potential to create or increase value for customers. Whereas value-stream managers focus 75% on management and 25% on leadership, the Business Unit Managers will focus 75% on leadership (growth, mainly) and 25% on management. They will incubate new business, drive business in new countries, and help to create new technologies; and they will do all of this with the support of the entrepreneurial-minded value streams.

Already, the unit leaders have recaptured lost business and they’ve identified another millions in potential new business. In fact, a new product is “being incubated” at the moment, Lichtenberger said, and he wouldn’t be surprised if it soon grows into CLS’s sixth value chain. “Things just can’t stay the same,” he explained.

What a Value Stream Looks Like

At Parker Hannifin’s Climate Systems Division, value streams are where everyone’s at — literally. Value-stream manager Steve Merriman spends time in both an office area, where his support staff interacts directly with customers and other team members; and on the plant floor, where production employees produce a variety of flow-control devices.

“I’m very autonomous,” he explained. “I run this like a business, and they [value-stream team members] know it’s my job to run it like a business.” On the plant floor, the flow-control operations are contained in one area, just as the other five value streams have their own areas. Operators take production orders directly from a computer terminal, where they’ve been uploaded as customer orders are placed. They will turn the work around in about a day. Production is split between manual and automated, with operators pulling from a-day-or-less worth of WIP (machined copper and brass pieces). In several areas, projects are underway to increase automation as a way to improve quality and efficiency.

Near Merriman’s office, operators have been filing in information about their tasks as part of a standardized work project. “It divides the work into elements and then we can kaizen those throughout the year,” Merriman explained.” All of the value streams pull incoming materials and supplies from an inbound freight area that is divided by value stream. Operations Manager Lichtenberger said the material-handling area is half the size and contains half the inventory that it did two years ago. He thanks value-stream management for that. “I’ve got a buyer/planner in each value stream. They’re not writing contracts. All that they’re focused on is getting their [purchasing] scheduling properly done for their production schedule.”

The buyer/planners know more about what’s happening on their portion of the production floor than their predecessors, who lacked the information exchange that occurs when value-stream team members are physically located together. “Before, we didn’t understand how our decisions affected other groups,” Lichtenberger said.

For More Information

The Parker Climate Systems Division is a world leader in distributors, couplings, service valves, check valves and value-added assemblies for Commercial and Residential Air Conditioning Systems.