One thing? I don’t know – how about three? First, lean is a people development system. Let me say this again. Lean is a people development system, which means that we aim to develop people to the fullest of their abilities. There are three tricky aspects to this:

- As Jeff Bezos says in his latest shareowner letter, if you take me on your basketball team, you can teach me many things, but you can’t teach me to be taller. Every lean activity is first an opportunity to discover the people who take to it with enthusiasm, ingenuity and initiative, those who won’t try anything new ever, and all those in between. It’s no secret that success depends on the quality of your management team. Lean activities are designed to reveal leadership talent on the one hand and give more responsibility and autonomy to the people who prefer to remain in their roles and not seek more.

- We can’t teach people. We can’t even train them. They’re adults. The only thing we can do is offer experiences and hope that they’ll get it and click. So lean is low in classroom training but high on practical activities to, hopefully, create opportunities for people to “see,” think deeply and learn to seek a better way of doing whatever they are currently doing – which is why we focus on wastes at first, not just to “eliminate” waste from the bottom line, but mostly to show easy topics for people to think about in a lean way.

- The gains achieved from the activities themselves don’t matter as much as the learning people get from them. The assumption is that if people familiarize themselves with a situation, then learn to manage it better through lean tools, they will do every other aspect of their job better, as this is a system. The aim of each lean activity is developing a sense of responsibility, initiative and creative thinking through hands-on trial and error. The activities themselves (the lean tools) are more about testing and measuring than actual improvement per se: when people better understand what they do and what they ought to do, the process improves.

Major Misunderstandings

This is probably the most critical point, and the largest misunderstanding. Lean is not a bunch of tools to fix processes and eliminate variation for greater compliance.

Lean is a learning system to give people a chance to better understand their job and progress through a structured set of activities oriented towards improving safety and quality, reducing lead-times, reducing total costs, and improving energy performance.

Lean is not a bunch of tools to fix processes and eliminate variation.

The second critical point one should not lose sight of is that there is no “lean” without just-in-time, without some form of kanban, pull, and lead-time control. The central point of lean is to find a way to increased competitiveness in situations of complete uncertainty and volatility. In order to navigate the blue ocean of innovation (and not get stuck in the red ocean of traditional competition where all the sharks are) we need a compass. This compass is lead-time.

The compass is built on three assumptions that work in any situation:

- Do not produce things people don’t want. Because we don’t have a crystal ball about what people do want, always come up with new stuff at a regular cadence and watch carefully what people take or don’t take. Understand what is heritage, that you want to keep, and what has to change to be more in tune with the spirit of the times. Understand what is rework and fix the root causes of it. Do not ever knowingly deliver a flawed piece of work thinking you’ll deal with the customer later.

- Only do work that is asked for, which means not to do work on in advance knowing that it’s part of your job, but actually do work for someone when they specifically ask for it. In particular, this means doing jobs one at a time, on demand, rather than preparing a batch ahead of time, hoping that customers will ask for it in the future.

- Measure the lead-time of your response time to any job request. Any job has two elements: discovery and delivery. The discovery part requires creativity and is unpredictable. The delivery part requires mindful delivery, but should not have any improvisation in it. The ratio between discovery to delivery varies of course, according to the work, but at some point, any repetitive job should have a higher part of delivery, and the unpredictable should become predictable, which should stabilize the lead-time. Measuring the lead-time and seeking to reduce it is the key to learning mastery about each job.

Learning to pull, usually with kanban, is the one technical barrier to entry in lean – many lean books actually try to convince you that you can do lean without kanban, but the truth is lean at Toyota really took off with kanban and the associated lead-time control for very practical reasons. Without the compass, improvement programs get lost in improving things that should be eliminated or that don’t matter much and local improvements never add up to competitiveness improvement and bottom line results. However, this means that leaders have to get into pull systems and understand them in depth – something they often feel is beneath them or too hard to slot in their busy schedules. In any case, lean doesn’t make any sense without just-in-time and pull.

To succeed with lean you must understand deeply that we don’t seek to optimize the current situation by better organizing people, we seek to motivate people to think and take the next step, to change how they work and where they work – and this can only happen by getting out of the office and going to where value-added work is done, physically, every day.

What ultimately pays in bottom-line results and fundamental productivity is increasing the flow of ideas, as Alex Pentland has proven in Social Physics. Increasing the flow of ideas increases the vigor of the company and the vitality of the teams – and delivers hard results. Lean is a structured method to do that and align ideas from the bottom-up with the larger challenges of the company defined by its leadership.

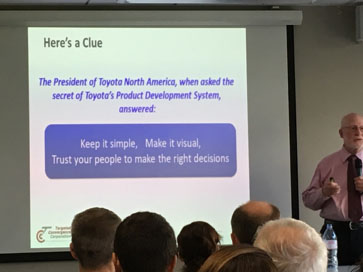

Michael Kennedy, a pioneer of lean engineering and knowledge systems has this great slide about asking a Toyota executive about the secret to the company’s success.

After a long pause, the answer was “Keep it simple, Make it visual. Trust your people to make the right decisions.”

What is not so simple is what to keep simple and make visual. Lean is, in fact, a bunch of techniques for visualizing work so that every person can tell you with confidence:

- The next step to do to succeed at their work today

- The next improvement step of their work to succeed tomorrow

The third – or first – key to lean success is to understand how deeply “genchi genbutsu” — go to the workplace and support improvement and problem-solving — transforms management practice and liberates efficiency.

The management line turns into a chain of help and progressively, mutual trust builds between frontline associates and managers, creating a completely different kind of company. Progressively lean leaders learn to manage their business, even large ones, by workplace visits and deep dives – paying close attention to how people solve typical problems and understand the direction the company intends to take.

To sum up, I’d say the three deep practices lean teaches: you must go to the workplace, put customers first, and show respect to the people working there by asking “why?” From these core practices, we seek to learn to solve the right problems, better work with our teams (and make the teams work better together) and stop doing stupid, wasteful stuff.

The deepest lesson of lean is that in order to transform others you first have to transform yourself. People follow leaders whose competence and judgment they trust (whom they think will lead them to success) and who they trust (because they see the leaders’ solutions includes them). Lean practice teaches you a better understanding of how things work, and how to work with people to respond more flexibly to evolving customer demands and to improve buyability and profitability of what you produce. But to start with you’ve got to adopt a new pair of glasses and look at work through people first.

Managing to Learn with the A3 Process

Learn how to solve problems and develop problem solvers.