Launching Lean at Danaher

Ah, nothing like a trip down memory lane. I’ve written about some of this before so forgive me for any redundancies. I’ll try and highlight some of the key lessons learned as we go along.

When we started lean at Danaher in 1987, the company was approximately $1 billion in sales. We had 13 separate and totally unrelated companies. Corporate headquarters were located in a small house under the Key Bridge in Washington D.C. and consisted of the Rales brothers, their two executive assistants, the CFO and a finance staff of less than ten. All the operating activities reported to two Group Executives, myself and John Cosentino. We shared an office and assistant in the factory of one of my Group companies, Jacobs Engine Brake (known as Jake Brake) in Bloomfield CT. We met monthly with the Rales brothers in Washington D.C.; but the day-to-day operations were the responsibility of John and me.

We didn’t know anything about Toyota’s 5S approach at the time. We just did this because it made common sense.When I arrived at the end of 1985 two of my companies, Jacobs Chuck (drill chucks) and Jake Brake (engine brakes for class 8 diesel trucks), were really struggling. At that time only two people in Danaher had any exposure to what we called Just-in-Time: myself, from my first general manager’s job at General Electric, and the guy I had appointed as President of Jake Brake, George Koenigsaecker (George K.) from his prior experience at John Deere and Rockwell.

We knew we had to make drastic changes at Jake Brake or we would lose it, and we both wanted to use Just-in-Time as the approach. Our auditor at the time, Arthur Anderson, had a consulting arm that was selling Just-in-Time knowledge so we started with them in 1986. While they were pretty slow, way too expensive, and loved power point presentations, we did create our first couple of cells.

At the time Jake Brake was a heavy machining operation which looked like a dark, dirty cave. George and I decided that we needed to change. So each time we built a new cell we added better lighting and repainted everything in that area: walls, ceiling, floors and machines. We even put potted plants in the first cell just to show how different the new look was. We wanted everyone to want their work area to look like that. We didn’t know anything about Toyota’s 5S approach at the time. We just did this because it made common sense. This turned out to be a great lesson that we both carried forward into our future lean endeavors.

We had a couple of cells but to be honest they didn’t work very well. We were reading books by Ohno and Shingo and especially a book called Kaizen by Masaki Imai. In the spring of 1987, George K. noticed that Imai was hosting a five-day kaizen seminar in Hartford CT, which was just down the road from Bloomfield. George signed up about five of his people, and I attended the first two days. To do the training, Imai brought in the Shingijutsu Company from Nagoya, Japan. This was just 3 people who had spent their whole careers at Toyota, and for the 10 or so years prior to founding, Shingijutsu had worked directly for Taiichi Ohno implementing TPS in the Toyota first tier supplier companies.

These individuals were the real deal. George and I agreed that we needed them to come and help us. George K set out on this task and was relentless. He took them to dinner and brought them back to the plant late one night. They started immediately moving things around, which almost caused a riot with the union. They came again later in the week when both George and I could be with them. We said, “what do you think?” They said “50 percent. Everything can be cut by 50 percent.” Later they told us they said 50 percent because they didn’t think we would want to hear the real number.

We liked that as we were only thinking about 30 percent, but when we tried to get them to come work for us they declined. “We are too old, it is too far away, we don’t speak English, etc. etc.” We finally said: “But we have great steaks and lobsters and lots of golf.” They loved golf, so they agreed to meet with me and the President of Jacobs Chuck in a couple of months when we were going to be in Japan. At that meeting they agreed to come work for us. Mr. Iwata, their President said, “We will show you manufacturing magic.” Wow, was he right.

We started working with them in Jacobs Chuck in Clemson SC, which by the way also looked like a cave. We started with a plant tour which we thought would take about an hour and a half. We got only about 100 yards into the plant when they said, “Stop, we’ve seen enough.”

We returned immediately to the conference room, where Mr. Iwata went to the white board and in big letters wrote NO GOOD! He turned around and said: “Look, everything here is no good, what do you want to do about it?”

Ok, we got it. We formed two teams, one for our industrial chucks and one for assembly. We had four conveyor belt driven assembly lines, and so naturally the first thing Iwata said was “I hate conveyer belts, get rid of them.” Yikes! The other team, with Nakao and Takanaka, started moving equipment right away (machines that had been in the plant for more than 15 years without being moved) and by the end of the day had created the first cell. The great lesson we learned here was to listen and learn. Don’t push back. We found right away that lean (Just-inTime back then) was “learn-by-doing” and we wanted to learn.

Rolling Up Early Gains Beyond Incidental Improvements Into A Broader System

For the first couple of years Shingijutsu just focused on Jacobs Chuck and Jake Brake. Both made great progress. George K., along with his VP of Operations Bob Pentland and a new hire from a local company Ensign Bickford, Mark DeLuzio, really took the lead. Mark helped us initially in finance by moving us away from standard cost accounting and toward something similar to what is now called lean accounting, and later became instrumental in creating/running the Danaher Business System (DBS). Switching to lean accounting was another big lesson as it allowed us to finally see what was going on and didn’t fight lean as standard cost accounting does. It also created great productivity in finance as Mark was able to go from 25 to 9 people and close the books in a day and a half.

George K and I were learning that Just-in-Time was the greatest strategic weapon that we had ever seen.As we realized early on that lean was a learn by doing exercise, we spent as much time with the Shingijutsu consultants as we could when they were in town. On the shop floor, in kaizen teams, at dinner every night, asking questions and playing golf with them on Saturday and Sunday before the kaizen week started. This was another lesson, which is that all leaders need to emerge themselves in the details of lean and become lean experts themselves if they want to have a successful lean turnaround.

Another lesson learned was that from the beginning George K. and I both saw that the Just-in-Time that we were learning was the greatest strategic weapon we had ever seen. Shingijutsu wasn’t teaching us this explicitly. But we saw that if you could cut your lead times from weeks to days, increase your productivity, drastically improve your quality and free up over half your floor space by removing the waste from your operations then you would have a huge strategic advantage. In fact we created an informal pact: “whatever Shingijutsu told us to do we would just do it no matter how crazy we thought it was.” About half the time we thought it was really crazy but we did it anyway. A lot of times things didn’t work well at first (in fact most of the time) but we never let it go back to what it was. We just kept pushing till we solved the problems and made it work. Another lesson learned.

A couple of key Toyota principles are “respect your people” and “go to gemba” (the shop floor). We had never heard of these at the time but they seemed to be powerful common sense and we implemented these principles anyways. For example, Brake was a union environment (UAW), so we involved the union in everything we did. We were always honest and up front with them. We treated them as equal partners not as a union. At first this confused their local union president, Big Benny, as he thought perhaps we were trying to trick him. But as we kept proving that every move we made was better for our work force we eventually formed a great relationship. We knew that the best ideas for removing the waste would come from the people doing the work, and that always proved to be true.

I remember forming a component parts cell where we got a lot of pushback from the operators. They objected that we were moving the machines too close to each other and it wasn’t safe, etc., etc. We said “just try it and see.” We came back a couple of weeks later and they had shrunk the size of the cell by more than half by moving the machines even closer together. One of the biggest initial complainers then said, “Hey, this is great why didn’t we do this before.” Lesson learned: respect and listen to your people.

The “go to gemba” part also just made sense. George K. moved his whole staff out of the office block attached to the plant an into a small stack of offices in the middle of the plant. His VP of Operations, Bob Pentland, went a step further and put his desk right on the noisy shop floor. This was another lesson learned that I carried with me when I became CEO of The Wiremold Company. After we reorganized into value streams (product families) we had the value stream team leaders all sit on the shop floor right next to the equipment that made their product families.

As Jake Brake improved we were dropping inventory like a stone, and with Danaher’s standard cost accounting our numbers weren’t looking too good. In fact the Rales brothers called a “special emergency meeting” to see what was going on. Well George K. and I knew that if we just sat in the conference room and went through the numbers it would not be good for us and they would never get a sense of the great gains we were making. So we agreed that we should start the visit on the shop floor. George K. then came up with the brilliant idea to have the workers in each area (all UAW members) conduct the tour. This took about three hours as our union guys were really into it. When we finally got to the conference room there was no review of the numbers. The Rales brothers, to their credit, just said, “Wow, how fast can you do this in the rest of Danaher?” Whew, we still had jobs but also a big challenge. It got bigger when we asked Shingijutsu for help and they said no—not until we got Chuck and Brake to be much better.

Energizing a President’s Kaizen Corps of Improvers

We were going to have to do this on our own. We knew that it would never work unless we got the Presidents of all 13 Danaher companies to be the lean drivers in their own companies. To do this we had to teach them lean. So George K., John Cosentino and I, decided to create the Presidents Kaizen. First we took all 13 Presidents and their VPs of Operation to Japan for a week to visit some of Shingijutsu’s more advanced Japanese customers. When we got back, Cosentino and I essentially ordered all the Presidents to participate in a three-day kaizen every six weeks in one of Cosentino’s factories.

They weren’t too happy about this at first but the gains we got every time were so big that this quickly changed. They went from “gee, why do I have to go?” to “When is the next one, I don’t want to miss it.” This in turn started We realized that this lean work would never work unless we got the presidents of all 13 Danaher companies to be the lean drivers in their own companies.to create a culture of lean within Danaher, even though it was done in an informal way. To help facilitate this I created a kaizen promotion office reporting to me. At first it was just one guy, Bill Moffitt, but we needed this to do the advance work and pick the kaizens that the Presidents would work on. Another lesson learned, the importance of a kaizen promotion office.

As Jake Brake improved we learned another valuable lesson, which is that at some point you have to get the customer involved if you are to continue to improve. This first came up with one of Jake’s biggest customers, Caterpillar. They were only ordering once per month, which caused lots of unnecessary inventory for both us and them. As we improved we talked them into ordering once per week. This didn’t last too long before they wanted to go back to once per month. We had to go further up their management chain to get them back to once per week. We eventually got to three times per week to the great benefit for both companies. I have seen this happen over and over in my various lean conversions. The more lean you become the more you outrun your customers and in order to deliver more value to them you need to get them to make some changes as well.

Jake Brake’s results are as follows:

| 1988 | 1999 | |

| Revenue | $65M | $220M |

| Headcount | 550 | 575 |

| Floor Space | 240,000 | 240,000 |

| Inventory Turns | 2X | 25X |

| On Time Delivery | <20% | >99% |

| Productivity | 3.0 | 35.0 |

| Operating Income | 4% | >30% |

| Development Cycle | 72Mos. | 16Mos. |

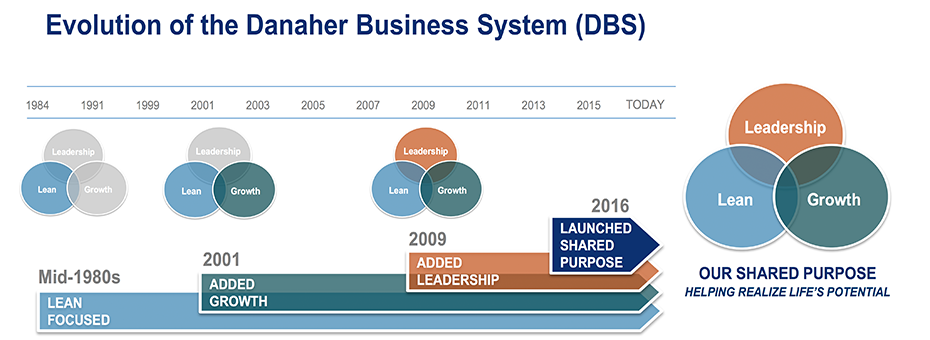

Danaher was Shingijutsu’s only US client for the first four years. They eventually expanded to work for all of the Danaher companies with great results. Both Cosentino and I left in 1991 and took them with us. George K. became a Group Executive after I left and took over the Tool Group, which was created with the acquisition of Eastco Hand Tools. He moved Mark DeLuzio into the kaizen promotion office role and made huge improvements. Together they added Hoshin Planning to our existing kaizen approach and created what is now known as the famous Danaher Business System.

Beyond Danaher

George K. moved on about a year and a half after I did and ran the Hon Company’s major furniture business, where he again made major improvements. Mark DeLuzio remained head of the Danaher Business System Office for nine years and was the driving force behind the rapid integration and conversion of Danaher’s continuing string of acquisitions for many years. He continued to adhere to the principle that Mr. Nakao and Shingijutsu taught us early on and this in large part has led to Danaher’s tremendous success. In fact, after George K., Bob Pentland, John Cosentino and I left, Mark was the only one remaining with the knowledge to be the driving force for lean in Danaher and deserves a major amount of the credit. He created the leadership development program where future leaders rotate through the DBS office for development purposes. He created the M&A integration process as well as the due diligence process as it related to DBS. And along with Larry Culp, Danaher CEO (and now the CEO of GE), developed the strategic planning process for all of Danaher. You can learn from Mark by buying his new book Flatlined: Why Lean Transformations Fail and What to Do About It.

I hope you have enjoyed this trip down memory lane. All of the lessons learned are still applicable today. Making such drastic changes was a lot of work but at the same time was a lot of fun. We crammed more learning into just a couple of years than most people experience over their whole careers. Danaher is a great example to follow and I hope you do.