Traditional approaches of organizing by function rather than value stream build an enormous amount of waste into any system. And yet most companies (both manufacturing or non-manufacturing) are organized this way, and rarely question this. They see their sales growing and are reasonably profitable; they have been doing things this way for a long time and it works. So why change? They ignore those crazy lean people who seem to hate this approach and want to get rid of it entirely. Going lean would mean working to something called Takt time and implementing one-piece-flow–radical changes that would call for moving equipment, retraining people, and yes, changing our mindset about how we organize everything. It sounds risky, but this is not only a reasonable request but one that will eliminate an enormous amount of structural waste.

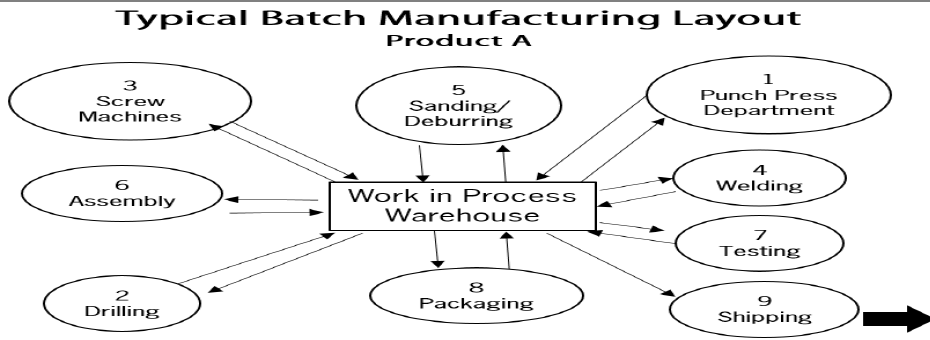

Let me illustrate. The chart (above) shows a typical layout for a manufacturing company. All the equipment is located in functional departments containing the same type of equipment, e.g. punch presses, drilling, welding, sanding etc. Each of these departments is headed up by managers who are very familiar with the type of equipment they are responsible for. The machines, even in the same department, all run at different speeds. They also have different setup times, most of which are quite long (2-3 hours) and have been that way since the machines first arrived at the plant. This is largely due to the design of the machine and the fact that the machine manufacturers were focused more on capability and run speed and not too concerned about setup times. In any event, these setup times are taken as a given by both the operators and management.

So, what’s the problem? Let me list a few:

LONG LEAD TIMES

These functional departments are spread out all over the plant and are not close to one another. As a result, the parts are moved many times, and travel long distances before they can be put into the final product. There is a W.I.P. warehouse just to store them as they make their way through the process. This adds extra space and is expensive. All the moving of parts also adds to the cost. To get the parts through this maze then is very complicated and results in long (4-6 weeks) lead times.

EXTRA PAPER WORK

To keep track of all this requires extra paper work. Things like routings, move tickets and labor tickets are all pretty common with this type of structure even though they are all non-value added and just add extra cost both in the shop and in the accounting department.

MRP SYSTEM NEEDED

Trying to keep track of all this without an MRP system is impossible. But these MRP systems are expensive and very complicated. In order to work properly they tend to lock in the long lead times as they force compliance with the system which is pre-programed to a set lead time, say 6 weeks. If you want to shorten the lead time you have to re-program the system which is not easy.

CUSTOMER SEPARATED FROM THE FACTORY

Most companies organized this way running to an MRP system end up separating the customer from the factory completely. The MRP system spits out a monthly list of what and how many to build based on some form of forecast. The factory never sees the actual customer demand, it is just told, “shut up and build the forecast.” This lack of connection with the voice of the customer restricts the ability of your most valuable asset, your people, to help solve customer problems.

FORECAST IS ALWAYS WRONG

With a 6-week lead time, forecasting customer demand with any accuracy is an almost impossible task. But this type of structure relies on having an accurate forecast. To offset this built-in problem companies are forced to carry excess inventory. This of course adds to the overall cost. Next they try and buy a new, very expensive forecasting system. This just adds to the cost. Then they may create an expediting department to try and satisfy the customer when the forecast was wrong and they run out of stock. Another expensive, non-value adding activity. Then of course there is the wasted time and energy in the management team due to the finger pointing when the forecast is wrong. All waste.

QUALITY PROBLEMS HARD TO SOLVE

With this structure, quality problems are hard to solve–not just in real time but long after the fact. The defects could have happened 6 weeks ago. There is no way of identifying quality issues when the occur. Nobody can say exactly what department caused them. Even if we knew this, say, its in department #3, what machine and/or which operator caused the problem? There are 12 machines and 24 operators on 2 shifts in department #3. On top of this whose raw material was it? The company buys from three different vendors, and six weeks later it is impossible to tell whose raw material it is even if the raw material caused the problem.

INFLEXIBLE WORKFORCE

In this type of structure the workforce typically has a very narrow skill set. One person one machine. Thus if too many people are out on a given day it can reek havoc with the schedule.

MAKE ABSORPTION HOURS

This type of structure usually goes hand in hand with an absorption accounting system which puts a lot of focus on keeping everything running (even if there is no demand) in order to make the budgeted absorption hours. So if one of the 8 machines required to make product A is down today the finance department will insist that the other 7 machines still run full bore to make the absorption hours even though they can’t make a single product that day that could be sold to a customer. The machines run at different speeds so this just results in building excess inventory in unequal amounts. 400 bases and 100 covers, for example and does nothing but raise costs.

Similar issues arise due to similar functional structures in non-manufacturing companies. Hospitals are a great example as they tend to be organized in fiefdoms that are very insular in nature. To get treated even for a simple injury like a broken arm you might have to pass through 10-12 separate fiefdoms. This tends to result in lots of excess waiting time and filling out the same basic information multiple times, all non-value added. For more serious health problems a miscommunication between the fiefdoms can cause serious medical problems even death.

Banks also tend to organize by functional specialties which can add extra time and cost to even simple transactions. For example if you did a value stream map of a loan application process that took three weeks to get approval you would likely find that the actual touch time labor involved was less than 30 minutes. The rest was tied up in moving the application from department to department, and even the occasional re-do required if something was missed. Life insurance companies are not much better. The underwriting department assisted by the case management department for example might take 45 days to return a quote for insurance where most of that time is spent with the application waiting for something to happen. I once helped an insurance company with this problem. It was taking an average of 48 days to underwrite a policy and the average underwriter was doing 15 lives per week. Applying a few lean principles we were able to get over half of the policies underwritten in under 20 days and the underwriter was doing 88 lives per week.

Moving to lean and flow eliminates all of these structural problems. It lowers cost and improves quality, shortens lead times and is more responsive to the customer. It allows you to respond to the customer need directly, not relying on a forecast and building things in big batches in advance hoping you made the right thing (you almost never do). So while you might be able to survive and be profitable using a traditional functional structure the fact is that you will be leaving a lot of money on the table. That’s of course up to you. As long as none of your competitors become lean you might be all right. If one of them does become lean, however, it won’t be long before you will start to be in trouble. But, if you can start to understand the waste built into a traditional functional structure maybe then you can start to change before it is too late.