When Dave Westphal talks about how to respond to a machine breakdown, he sounds more like an emergency room doctor than a plant manager. “Treat it like a wound,” he says. “You have to respond immediately to insure quick recovery with as little pain as possible.”

His medical-emergency approach to downtime comes from experience. Westphal’s plant recently had “wounded” machines in several key processes. The cure — and the lesson for lean thinkers — was to begin treatment with a regimen of thorough problem solving that identified and eliminated the causes of machine downtime in order to create stable processes. The lesson is especially true in machine-intensive production environments such as Delphi’s Plant 1.

Delphi Plant 1 at a Glance

- Makes electric power steering columns, rack and pinion gears, intermediate shafts.

- Opened January, 2004, Saginaw, MI, as part of Delphi Steering.

- Uses the Delphi Manufacturing System (DMS), based on the Toyota Production System, to drive improvement.

Plant 1 is a newly refurbished facility, employing new team-based work practices, using all new equipment, making a sophisticated new product — automotive electric power steering systems. Opened in Saginaw, MI, in January, 2004, the plant receives nearly 100 different parts in near- net shape from 75 suppliers to machine and assemble complete steering systems from steering wheel connections to tie rods. The product is an important one for Delphi

because demand is expected to grow due to distinct advantages over traditional hydraulic products. Electronic systems are more precise, more compact, more efficient, more environmentally friendly (no fluids) and safer.

Many of the plant’s 138 machines are unique to Saginaw, designed specifically for the product and its precise tolerances. A Swiss-made grinder, for example, was made to shape a 10-micron taper along a metal shaft. A human hair is about 30 microns thick. To get machines like this working at a high level of uptime and precision, all conditions — tool position, speed, feed, coolant spray, clamping and locating mechanisms — must operate perfectly. Too often, they didn’t. Making the situation worse was that the most critical machines, such as the Swiss grinder, had the most downtime and stoppages.

When Westphal walked into the 65,000-square-foot facility as manager that January, it was running 24 x 7 to keep customers supplied, often by airplane. On-time shipments, defined as having the right parts on the right truck at the right time, were at 35%.

“If a one-of-a-kind machine went down, it went down for four or five hours and it went down hard.” For instance, when the Swiss grinder broke, “We didn’t know how to fix it, and worst case, we’ve got to call Switzerland for technical assistance or spare parts.”

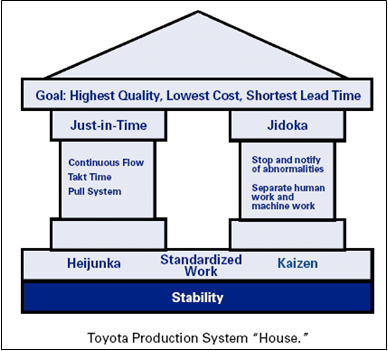

To find a permanent cure for the downtime epidemic, Westphal focused an improvement effort on the base of the Toyota Production System “house” diagram (right). “You can’t build a house of production unless you have a strong foundation,” he said. “So we started with creating stable processes. I kept my staff focused on basic stability concepts such as the five S, visual controls, preventive maintenance, and rigorous problem solving on our mechanical downtime problems. We drove a solid foundation under our production system house by working on eliminating small stoppages, and catastrophic machine failures.”

An improvement team set targets of 98% first-time- through quality (FTQ), 85% operational availability, and 100% on-time delivery and communicated them to staff and employees.

Improvement activities began with a Pareto analysis and a very practical philosophy. “If you know what keeps dinging you and you go fix it, you’ll get dinged a lot less,” Westphal explained. “So we immediately reorganized everybody around Pareto thinking

— where are the 20% of the machines that are going to give you 80% of the value for spending your time and money on them.”

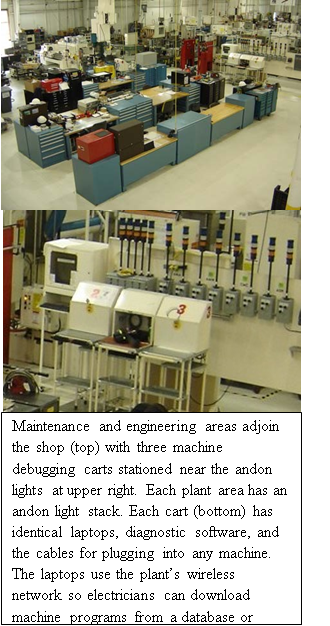

The facts for identifying the “dings” causing instability came from shop-floor observations of problems, equipment repair history stored in a maintenance program, and data from the plant’s andon system, which was being completed at about the time Westphal arrived. When a machine broke down or a problem prevented it from making the daily production target, the cell operator or its leader (an hourly employee called a coordinator), walked to a bank of andon lights between the shop and the maintenance/engineering area. The leader wrote a description of the problem on a card, punched the card on a nearby time clock, turned on the andon light for the cell, and placed the card in a rack. The technician responding to the signal punched the card, then punched it again when the equipment was up and running.

“We can tell the time the coordinator or operator said, ‘I have a problem.’ How long it took maintenance to start the job, and how long it took a guy to fix it,” said Westphal. “You can tell a lot of things from simple punch cards.”

In August, a Pareto analysis of data from the cards identified the machines going down most often and the main causes of the breakdowns. The analysis also showed that the plant had enough trained technicians to respond and diagnose problems in a timely manner. Surprisingly, the big issue was the time needed to order and receive parts for servicing and repairing equipment that had gone down. Since the downtime problems weren’t anticipated at startup, the right parts often weren’t on hand. Of the 780 items in the tool crib, 58% weren’t being used. Employees were making four to five runs daily to get parts from cribs at Delphi plants nearby and eight to 10 runs daily to a vendor.

.

.

Slow-moving crib parts were returned for credit to an outside vendor. The number of parts stored was increased to 3,260 critical and frequently used items; their usage rate increased to the high 90% range. Small cribs holding parts used daily were installed at the cells. The outside vendor was given responsibility for replenishing parts in all the cribs based on a two-bin kanban system.

Machine Kaizen

That same month, the most problematic machines were attacked in kaizen workshops. Typically, kaizen is aimed at improving work methods or operator motions. “This works fine in most cases involving assembly, but in machine intensive plants with a lot of potential for downtime the improvement focus must include the machine, not only the operator,” said Art Smalley, a Toyota veteran who helped the plant stabilize processes. “The reason is that machines perform the value-added portion of work by removing metal from the part with specialized cutting tools. Operators load parts, change tools, run machines, perform quality checks, and perform some final assembly operations.”

A retired Toyota veteran from Japan named Tom Harada visited the plant and conducted the initial week-long machine kaizen session. The structure of the workshop included collecting breakdown data on the worst five machines and directly observing them. Mechanical problems were segmented into categories such as minor stoppages and major breakdowns. The causes for each of these problems were probed using the five-why technique and direct observation. Simple cause-and-effect tests were conducted where possible. Emphasis was placed on creating effective countermeasures and fabricating simple mechanical improvements that would deliver a big improvement in machine performance. Most problems were eliminated by Friday. Written improvement plans, including action items, were drawn up for more stubborn problems. These problems were attacked by teams of engineers, operators, and maintenance technicians during a 90-day period.

“When we could not fix a machine internally, we brought in the machine manufacturers and told them, ‘We don’t know why your machine isn’t working but it’s not, so go out to the shop floor, stand with it, and find out why,’” said Westphal. “I’m not shy about calling up the president of a company that manufactured a machine and telling him it’s one of our worst, and if you want to prove otherwise come see me. Most of those guys will show up on an airplane the next day because they don’t want a bad name. If I’m wrong, I’ll pay his bill. If he’s wrong, he pays and fixes the machine. Nine times out of 10, they pick up the tab.”

Westphal estimates Plant 1 went through “three generations of machine kaizen in 90 days.” With the combination of machine supplier, machine operators, and plant technical staff huddled in one room, results came quickly. For example, a critical machine used to hob gears seized up when it got warm. When the plant improvement team got together with the machine supplier’s rep to review data and observe operations, the supplier discovered that the chuck had the wrong dimension. “It was machined down right away in the tool room and set properly. Problem fixed,” said Westphal.

Concurrent with the machine kaizen effort, a total productive maintenance (TPM) workshop also was held onsite to start establishing the culture and discipline required to support high uptimes in machine intensive environments. Initial emphasis was placed upon basic operator tasks for daily cleaning of machines, fixing coolant and hydraulic oil leaks, maintaining proper tool change intervals, collecting better repair data and root cause problem solving to fix the most chronic problems. Equal emphasis was placed upon involving operators, maintenance, engineers, and managers to ensure it was an organizational priority and not just a one-time event. “It is not necessary to implement a full blown TPM program to obtain a lot of the benefits,” said Smalley, president of Art of Lean, Inc. “Sometimes just focusing the right part of the organization on the six major types of equipment losses and establishing countermeasures for those can obtain a lot of the benefit.” Typical losses include breakdowns, changeover losses, minor stops, speed losses, scrap or rework, and yield losses at start up.

As stability improved, cells were able to establish better one-piece flow. Between cells material flow is maintained by small buffers. Buffer size is adjusted daily, based on such factors as mean time to repair, mean time to failure, response time to breakdowns, and vacations. “In my opinion, you’ll never be able to run a manufacturing operation as complex as we are in one-piece flow,” said Westphal. “There’s a belief in the U.S. that one-piece flow is the Mecca of manufacturing and we believe that is what the Japanese do. I’ve spent as much time as most people in Japanese facilities and they always have small disconnection buffers between lines in machine intensive plants. They aren’t that big, usually only five to 15 parts because they have phenomenal response systems.”

Plant 1 now averages buffers of 1.5 to 2.0 hours between cells, a big improvement from when several days were needed. During a shift, the buffers might flex down to .5 or .7 hours. “That’s when I get a bit antsy,” Westphal admits. Conversely, if a buffer gets up to three hours, an operator is moved to another cell. If a machine goes down, the other machines continue to make parts that are held temporarily as WIP until the broken machine is fixed. “In too many plants if a machine breaks, people are standing around idle, while someone works on one machine. Here if a machine breaks, everyone keeps working,” said Westphal. When the machine is fixed, extra people will be assigned to the cell, or it will run through breaks and lunches to make up the lost production and get back into balance as soon as possible.

Shop-Floor Kaizens

In tandem with the machine kaizens, the plant implemented more traditional shop-floor kaizen workshops every couple of weeks, based on the most recent Pareto analysis of the top problems in a cell. This kept the improvement effort focused on “where the money is right now,” said Westphal, who avoids creating a rigid kaizen workshop schedule for the year.

Pareto Strategy

When is it time to move on to the next issue on the Pareto chart?

Dave Westphal suggests applying the 80/20 rule here, too: “Eighty percent of the value in solving issue number one is there for 20% of the cost. If you kill 80 percent of the big problem, stop. You’ll be below numbers four, five, or six. You don’t have to drive number one to zero. Once it’s below the next highest bar, get off of it. Maybe three kaizens from now, you’ll come back to it.”

The shop-floor workshops focused on such problems as improving cell layout, balancing work among operators to takt time, reducing cycle time, cutting changeover time, establishing or improving standardized work, or eliminating bottlenecks. They also would tackle less stubborn machine problems than the machine kaizen workshops.

A shop-floor kaizen team typically consists of engineers, the area supervisor (called an advisor) and four production operators, including an operator from each of the three shifts “to get cross pollination,” Westphal said. Workshops were preceded by three days of preparation during which engineers and cell operators observed and discussed the problems. Engineers were responsible for running the machines in question and making production targets during the preparation period. Operators and the cell coordinator observed and helped.

“Engineers always say it’s the operators fault and operators say it’s the engineers fault,” said Westphal. “Well, if you put the engineers on the job and have them run the job, they’ll know if it’s an operator issue or not an operator issue. “This is gemba-ism; this is go and see.”

Thus, when a week-long workshop began on a Monday morning, “there was no more fighting, there was no more arguing, everybody knew what the problems were,” Westphal noted. “Then you’ve got one solid week of fixing stuff and making machine moves. We normally saw movement on all the metrics — productivity, overtime reduction, first-time-quality, 5S, health, and safety. They all came up.”

Equipment was moved on the weekend, if necessary. By Sunday, 90% of the activities were completed. The remaining activities were described in a “kaizen newspaper,” basically a to-do list of what had to be done, due dates, and who was responsible.

“I’m not going to disrupt another cell team until I’ve finished what I started at the last kaizen,” explained Westphal, who believes management severely damages its credibility with employees by not finishing initiatives on the shop floor. Plant 1 management also gained credibility by being flexible. At one workshop, management anticipated moving seven machines. The team recommended moving three and using different standardized work than originally planned. “We took a leap of faith and did what they wanted to do,” Westphal recalled. “They upped their productivity by 30% percent.”

“It was one of the first events we did and it made us believers,” said Fred Kleinert, shop committeeman, United Auto Workers, Local 699.

Westphal said he made two commitments to Kleinert before the first kaizen workshops. One, was not to arbitrarily cut people to boost productivity. The other was to involve engineers and operators.

Having engineers and supervisors run machines during the preparation period, lets them “see the problems from the operators point of view,” said Kleinert. “The engineers develop a relationship with the people on the floor. They understand their problems once they experience them first hand. Now they have a better idea how to help you, and there’s agreement on what the problems are.”

Another benefit is that the culture became more cooperative. “Union against management isn’t going to work,” said Kleinert. “It didn’t work years ago when we had a lot of money to waste. It was like, I beat you today; tomorrow you got me. That’s not the way to do business, to be profitable, or have job security.” The key for management is to “talk, share information before it becomes an issue,” he said. “I’ll let you know what’s going on. You let me know what’s going on. It takes time to build that. You don’t do it in a day or a week but it comes.”

“At the end of the day,” said Westphal, “we still both recognize that if we beat up each other we haven’t done any service to the 240 people here making car parts.”

The “D” Word

Creating stable processes and sustaining them relies on the “D” word. “The word is discipline,” said Vince De Zorzi, general director of manufacturing operations at Delphi Steering. “If you have discipline, standardized work is easy. And the better you get in standardized work the better your first-time quality (FTQ) gets, the better your cost per unit gets, the better you know how to make the part, and the more stable you get. Plant 1 has become a benchmark plant, achieving not only stability, but also bottom-line continuous improvements. In addition, the plant has achieved 100% customer ship window attainment, through equipment improvements and the implementation of supplemental backup plans on critical equipment. Our goal is to be recognized as our customers’ best supplier and Plant 1 has protecting the customer as its number one priority.”

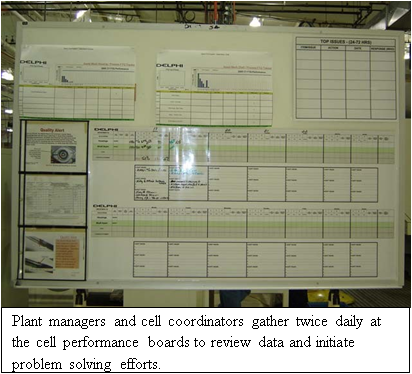

For the plant staff, standardized work means taking two walks daily to review the performance information on boards adjacent to each of the 10 cells. At 7:20 a.m. and again at 3 p.m., Westphal meets on the floor below his office with his direct reports, a group that includes the production manager, quality manager, engineering manager, maintenance manager, and the kaizen manager. If Westphal is out of town, the group still makes the rounds.

The walks are also an opportunity for managers to check 5S compliance in each area. “When your plant is sloppy, you can’t see what’s going on,” said Westphal. In plant 1, the floors are painted white and the lighting intensity is twice that of most facilities. “If we get an oil leak in a machine, we know it.”

Every board has key information arranged in a standard manner:

- Daily schedule attainment is posted in the center.

- A two week rolling record of schedule attainment runs along the bottom.

- FTQ by day for each machine in the cell and the cell overall is in the upper left.

- Hourly production count by machine is posted on the left. (Operators take the hourly parts count.)

- New issues, such as recent downtime or other problems that prevented the production schedule from being met are at the upper right.

At each board, the area supervisor and the cell coordinator discuss with plant staff any problems posted on the board. Together with the cell team, they begin the problem solving cycle of gathering facts, asking “why” five times to identify root causes, planning and implementing countermeasures, and following up. “The question I ask everyday,” said Westphal, “is did you make your plan and if not what are you going to do about it.

The emphasis is on the you. What are you going to do to make the cell make its count the next hour, the next shift, the next day? Once you get that culture, improvements happen really fast. People really start to live it.”

|

Delphi Plant 1 Box Score |

||

|

Measure |

CY 2004 |

CY 2005 |

|

Ship window attainment |

35% |

100% |

|

43 |

51.9 |

|

|

Quality (defects to customers as parts per million [PPM] ) |

150 |

6 |

|

Warranty field issues (complaints besides PPM) |

†94% |

|

|

Mfg. cost per unit |

†58.4% |

|

|

Scrap (cost per unit) |

†62.9% |

|

|

Productivity |

T26.2% |

|

For More Information

Delphi is a world leader in mobile electronics and transportation components and systems technology. Multi-national Delphi conducts its business operations through various subsidiaries and has headquarters in Troy, Mich., USA, Paris, Tokyo and São Paulo, Brazil. Delphi’s two business sectors – Dynamics, Propulsion, Thermal & Interior Sector and Electrical, Electronics, & Safety Sector – provide comprehensive product solutions to complex customer needs. Delphi has approximately 185,000 employees and operates 167 wholly owned manufacturing sites, 41 joint ventures, 53 customer centers and sales offices and 33 technical centers in 38 countries.

The Lean Enterprise Institute (LEI) runs monthly regional workshops on basic and more advanced lean tools, including a workshop by Art Smalley on Achieving Basic Stability that covers some of the improvement steps described above. LEI workbooks and training materials – all designed to de-mystify what a sensei does – show you what steps to take on Monday morning to implement lean concepts. Visit the LEI web site at www.lean.org

for more resources supporting lean transformations.

Glossary

(Adapted from the Lean Lexicon)

Andon

A visual management tool that highlights the status of operations in an area at a single glance and that signals whenever an abnormality occurs. An andon, which is the Japanese term for “lamp,” can indicate production status (for example, which machines are operating), an abnormality (for example, machine downtime, a quality problem, tooling faults, operator delays, and materials shortages), and needed actions, such as changeovers.

Five Whys

The practice of asking why repeatedly whenever a problem is encountered in order to get beyond the obvious symptoms to discover the root cause. The specific number five is not the point. Rather it is to keep asking until the root cause is reached and eliminated.

Standardized Work

Establishing precise procedures for each operator’s work in a production process, based on three elements:

- Takt time, which is the rate at which products must be made in a process to meet customer demand.

- The precise work sequence in which an operator performs tasks within takt time.

- The standard inventory, including units in machines, required to keep the process operating smoothly.

Standardized work, once established and displayed at workstations, is the object of continuous improvement through kaizen.

Takt Time

The available production time divided by customer demand. For example, if a widget factory operates 480 minutes per day and customers demand 240 widgets per day, takt time is two minutes. Similarly, if customers want two new products per month, takt time is two weeks. The purpose of t a k t time is to precisely match production

with demand. It provides the heartbeat of a lean production system.

Total Productive Maintenance

A set of techniques, originally pioneered by Denso in the Toyota Group in Japan, to ensure that every machine in a production process always is able to perform its required tasks. The approach is termed total in three senses. First, it requires the total participation of all employees, not only maintenance personnel. Second, it seeks total productivity of equipment by focusing on all of the six major losses that plague equipment: downtime, changeover time, minor stops, speed losses, scrap, and rework. Third, it addresses the total life cycle of equipment.

Visual Management

The placement in plain view of all tools, parts, production activities, and indicators of production system performance, so the status of the system can be understood at a glance by everyone involved.