Sam runs a small CNC Machining business. One department working one shift has 30 machines—25 people (working on those machines directly and another 5 people supplying materials—plus a supervisor. Pete wants to grow his business to keep pace with customer demand that is increasing 20% beyond his current volume of 5,000 rods a day.

Sam’s challenge (and yours) is to understand where exactly his team stands at this particular moment and what changes are necessary for growth. Pete’s guys and gals have always shipped on-time.

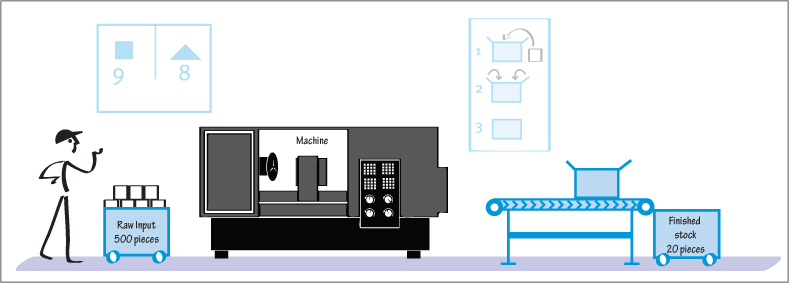

Each process looks like this:

Each machine cycle takes 2 minutes to make a piece. The human time is 8 seconds to unload, load, and cycle the machine. There are 5 seconds of walk while the machine is cycling to pack completed items and grasp new stock. The automatic time of the machine is 112 seconds. (Recall there are 30 of these machines and 25 direct people to work them). The shift is 480 minutes of work time. Any machine is down once weekly for 20 minutes. Quality is spot on (sure would be nice in the real world, wouldn’t it?). Machines are on wheels and can be moved around easily.

Samn’s daily customer volume is 5,000 of these little machined rods. Profit Margin on the product stands at 33%.

So, if you were Sam, what would you look at from a capacity and layout perspective? How about from an individual human growth perspective for the employees? Pete’s people have been working this way for 20 years. Your plan for change needs to address this as much as it addresses what technical changes are required. Remember, the technical aspects are important, but success or failure will be determined by your approach to change.

There are many issues bundled into this challenge. For example, consider how effectively the resources are being used. Can they be better utilized to capture the market growth available? This goes beyond just a cost perspective—how will you generate support for these changes and enthusiasm for continuous improvement?

Your assignment: Come up with a plan and share it in the comments section below. There are many possible ways to improve this situation, on both the technical and human involvement side of things. What’s yours?