I’m a long-time fan of Brasilian futbol (or as some of us call it, soccer). This World Cup, I’ve been won over by the Mexican team. Why? Coach Miguel Herrera. Why? His passion is infectious. As a fan, I love it.

Coaching, though, isn’t just one thing.

Coach John Wooden: Everyone Is a Teacher. Everyone Is a Coach.

John Wooden was arguably the most successful, probably the most influential, and certainly the most studied coach in the history of US sports. His UCLA basketball teams won 11 national championships over a 13 year span. But, his influence is more than a matter of wins and losses. He spoke very little about “winning”. Winning – the final numbers of the scoreboard – was the result of a process, of doing things the right way. And it was the way he coached that made a difference and led to his phenomenal results.

“Success is the peace of mind which is a direct result of the self-satisfaction in knowing that you have made the effort to become the best of which you are capable,” said Wooden when asked to define success.

Wooden’s approach was unique, according to researchers Richard Gallimore and Roland Tharp, who studied the processes of many coaches. They found that Wooden gave very few “motivational” speeches and rarely got overly emotional, whether up or down. What he did was simply … teach.

In their study of Wooden, Gallimore and Tharp recorded 2,326 discrete acts of teaching, which they categorized as:

- Compliments: 6.9%

- Expressions of displeasure: 6.6%

- Pure information (what to do, how to do it): 75%

Coach Wooden taught via what he called the “whole-part” method; he would teach an entire move or play and then break it down to work on its essential elements. That will sound very familiar to you if you know anything about TWI – Training Within Industry program – and its “job breakdown” process.

Swen Nater played for Wooden at UCLA from 1970-1973 and wrote a book with Gallimore about Wooden’s coaching/teaching style called You Haven’t Taught Until They Have Learned.

Swen says the heart of Wooden’s process was condition (moral, mental, and physical), skill, and team spirit. For Swen, “Steady improvement in several areas continued to provide me with motivation to reach my personal best, but nothing motivated me more than enhanced conditioning, skill, and team spirit. The better my conditioning, the harder I could work to improve my skills. The better my skills, the better I could give them to the team. As all three were improving simultaneously, I could literally see daily improvements. It was exciting. I felt good about myself.”

Coaching – Improving Performance and Developing People

Any leader’s job is to get the work done and develop the people doing the work at the same time. To accomplish these two objectives as separate activities is difficult if not impossible. So the lean leaders’ solution is to develop people through getting the work done. And one key means by which lean leaders do that is coaching.

Personal and Organizational Transformation: Capability for Capability Development

Lean transformation is personal and organizational. Swen’s story of learning from Coach Wooden is a great example of personal transformation. How does this relate directly to the organizational side of transformation?

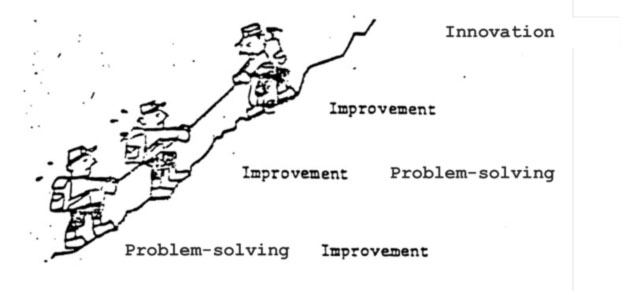

Taka Fujimoto, the foremost scholar of Toyota in the company’s home country, distinguishes between competing through price or product with competing through organizational capability. In his book, Competing to be Really, Really Good, Fujimoto notes that capability building is in itself a process with three layers: routine work capability, routine improvement capability, and evolutionary capability.

“Capability building is a step-by-step process,” he writes. “Organizational capability in regard to manufacturing comprises three layers. The base layer is routine manufacturing capability. That is the capability of producing the same product as competitors at lower cost, at higher quality, and with shorter delivery lead time.

“The second layer of organizational capability is routine improvement capability: the ability to achieve continuing improvements – kaizen – in productivity, quality, delivery lead times, and other facets of deep competitiveness. That capability consists of an organizationally ingrained capacity and predilection for undertaking problem-solving cycles continually, which drives relentless improvement in products and in production processes.

“Sitting atop routine manufacturing capability and routine improvement capability is the third layer: evolutionary capability; in other words, capability-building capability. That capability, anything but routine, is the capacity for tossing up new capabilities out of the soup of organizational chaos.”

Taka notes that gains are realized at different timeframes from these different processes – that capability-building is an “emergent process”, one whose pace cannot be rushed. Taka uses the phrase carefully to suggest “complex phenomena that arise from simple rules.” Through careful, mindful, repeated practice of specific methods, a systemic change occurs over time.

How to Develop Individual and Organizational Capability

The Organizational Learning movement, led by Peter Senge and others, has long taught about the powerful structure of double-loop learning: learning which questions deep assumptions in an organization – a conscious practice of reflection and inquiry that surfaces hidden, tacit attitudes in a way that they can be framed and addressed productively.

More recently, Mike Rother has led a movement that embodies lean thinking to actualize the structure and principles of double-loop learning in real-world practice. Practice that can be practiced and learned. Through the Improvement Kata and the Coaching Kata, a learner practices basic moves (work routines) while an experienced coach observes, checks, provides instruction as necessary to lead the learner to proficiency. “The Improvement Kata’s practice routines teach a scientific meta-skill that aims to change our habits of mind so our capabilities come to greater fruition. Practicing the Improvement Kata develops and mobilizes our creative capabilities and makes us better at achieving our goals,” according to Mike.

David Verble relays his own learning from Toyota’s Fujio Cho, who coached leaders to:

- Give them the job as their own.

- Let them think; let them try.

- Help them see.

- Force reflection.

And, essential to coaching in any style, any individual you try to coach has to be open to being coached … by YOU. As David says,

“Helpful coaching is a balancing act for the coach. On one hand you want to help the ‘coachee’ to be successful by making her more aware of what she knows and how she knows it and by prompting her to look at what she is thinking and consider what it is based on. On the other hand you have to allow the coachee to stay engaged in her own line of thinking without taking over the problem-solving thinking with your coaching or your own ideas.”

Learning to Coach

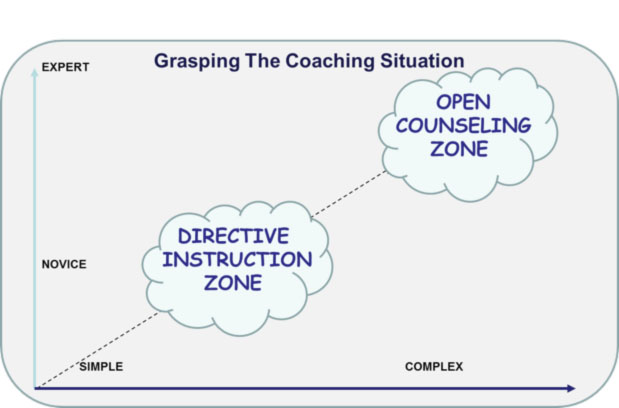

Coaching isn’t one thing; it’s many things, requiring multiple skills. Sometimes coaches provide the most detailed of instruction: “here is how you attach the part … this is how you handle the ball in this situation … here is how you change the oil …” Other times, we offer the most thoughtful of observations or questions to “force reflection” and lead to new levels of thinking, often far beyond what we – as questioning coach – may have been thinking. For coaches there is a “directive instruction zone” and an “open counseling zone.”

Master coaches I have known could move seamlessly from one zone to the other, instructing one moment and counseling the next. Can this level of coaching capability itself be learned? If so, how? Join us to explore these and related questions at the third Lean Coaching Summit in Long Beach. We are again joining forces with our partners at Lean Frontiers and friends at BeLikeCoach to host master coaches such as Swen Nater (the only player ever to lead both the NBA and the ABA in rebounding!) and David Verble (no NBA records of which I am aware), who will be among the many experts sharing their expertise and struggles – hope to see you there, too.

The World Cup is incredible fun. Whoever you root for, it’s thought-provoking to observe the coaches as well as the players. The players are practicing, playing, and learning. So too the coaches.

John Shook

Chairman and CEO

Lean Enterprise Institute, Inc.

a href=”mailto:jshook@lean.org”>jshook@lean.org

PS: And remember the words of John Wooden: “When you improve a little each day, eventually big things occur… Not tomorrow, not the next day, but eventually a big gain is made. Don’t look for the big, quick improvement. Seek the small improvement one day at a time. That’s the only way it happens — and when it happens, it lasts.”