Part two of a three-part series on Developing a Lean Quoting Process.

Part 1, “Why a Lean Transformation Requires a New Quoting Process,” which introduces the need for a unique quoting process that will allow you to quote faster and redirect your quoting team’s efforts toward the few key quotes that can increase your profits.

Part 3, “How a Lean Quoting Process Helps You Capture High-Value Opportunities” describes how setting up a Daily Opportunity Review Board helps your company strategically respond to high-value customer inquiries.

**********

When you view your lean transformation as a growth strategy, you’ll want to develop a lean quoting process that responds to customer inquiries faster than the competition and allows you to focus on high-value opportunities. Here’s a process that’s designed to quickly complete 95+% of all quotes, which frees up your value stream quoting team to spend time on the handful of large and/or special quotes that will truly increase your company’s profits.

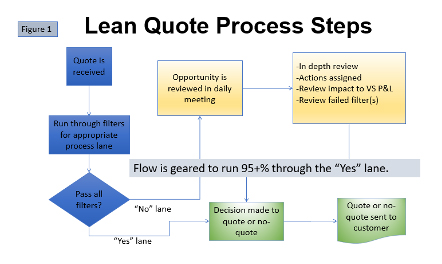

The basis of this new process is to develop filters around key criteria that are pass/fail in nature. Properly developed, 95% or more of your quotes should go quickly through this process and get to the customer in a day. The quotes that fail any of the filters will go to the daily meeting for these failed quotes. This regular meeting, I call the Opportunity Review Meeting. Here, the quotes that failed a filter will get the appropriate level of discussion necessary to determine if you will quote the business. And if you choose not to, how to capture the data for future consideration.

A high-level view of the lean quoting process.

To get through the “Yes” lane, you pass through four filters.

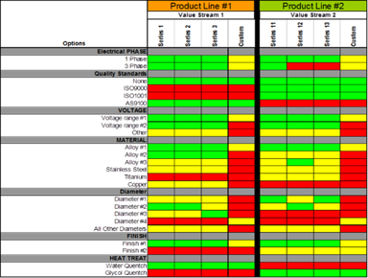

Filter #1 – Capability: This filter is a detailed, color-coded listing/matrix of what you can do on the plant floor. Green indicates easy things or things that you do well with standard material content. Yellow is for processes and/or material that you don’t do a lot or cause you some difficulty. Red is for processes/material that you can’t or won’t do.

An example of a capability filter.

Filter #2 – Capacity: Can your value stream handle the volume a given quote would bring to the value stream? If you are working with a lean box score, then you can look to the capacity section of the box score to see if you have enough capacity to take on the work. Another way to analyze the opportunity is by the size being quoted in either units or dollars. Units are a better volume determinant for small parts, but it is better to use dollars for large products. What you would do is create a filter that states that if the opportunity you are quoting is over a given number of units or a given dollar amount, it fails the screening and goes to the daily opportunity review meeting.

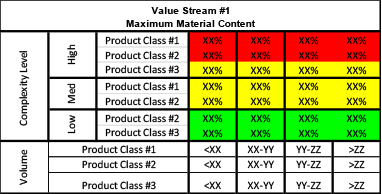

Filter #3 – Material content: This filter is determined by the material cost as a percent of the target price. (Target price is what the customer is willing to pay for the product. Remember, the cost to manufacture the product has no bearing on the price the customer is willing to pay. More on this in my upcoming book, Leveraging Lean with Lean Quoting.) To have this filter, you need to segment your products into distinct grouping by volume, complexity (high/medium/low) and product class. Keep all of these criteria at as high a level as possible.

An example of a material content filter.

You get these percentages by analyzing your sales data and seeing where you are successful. From there, you determine what level of material content is deemed acceptable for the smaller orders. A subset of this is how to handle this filter if you have a target price or if you don’t have a target price. If you have a target price, then you divide the material cost into the target price, and if the material content percentage is lower than the above matrix, it passes. If it is higher than the material content listed, it fails, and you either no-quote or quote at a higher price that passes the filter. If you don’t have a target price, you divide the material cost by the reciprocal of the maximum acceptable material content based on the matrix above (material cost/(1-max matl content %), and that becomes your minimum target price. You can always submit a higher price, but this is the lowest price.

Filter #4 – Does this job support your strategic direction? There is no template for this. To be able to make this decision, you need a close working relationship with your marketing team or whatever function drives this direction. You don’t want to be taking on jobs that don’t support your strategic direction. You need to understand your area of strategic attention, what is being cash-cowed, and what areas you are avoiding. Depending on which area the opportunity falls in will determine how you proceed with the quote.

If the quote makes it through all the filters successfully, then the business is quoted, and you go to the next quote. This part of the process will drive additional sales merely completing more quotes, and those quotes will get back to the customer faster. How many quotes for new business have you lost because you either couldn’t complete them in time or were so close to the deadline that the customer had already made up their mind about who was getting the business.

If the opportunity fails any of the filters, the quote goes to the daily opportunity review meeting, where you’ll realize the real growth. Because you have saved the quote team so much time from the above-listed process, they will have time to participate in this new daily meeting. And this meeting will focus its attention on winning the large or strategic opportunities that will drive exceptional growth.

In my next artice, I will discuss this daily Opportunity Review Meeting.