On my recent walks through companies, I’ve had an important realization. I had been assuming that in most companies the process steps in a typical value stream are sufficiently stable that it’s practical to introduce flow, pull, and leveled production right away. By “stable” I mean that each process step is both “capable” (able to produce a good part every time it operates) and “available” (able to operate every time it is needed.) Operational availability (OA) is a good term for the combination of the two.

I’ve long known that at Toyota an assembly process would launch with operational availability of about 97% and strive to reach 100% through kaizen. And I’ve known that in even the most complex transfer lines, like engine block machining, Toyota achieves and maintains operational availability of 85% or more. That’s striking evidence of stability.

But in typical operations I’m seeing recently I’m finding to my surprise that operational availability in cellular assembly (which is much less demanding than long car assembly tracks) is often no more than 90% even when there are no delays due to lack of materials. In complex machining operations OA is often below 60% and sometimes as low as 40%. And these are household name, global companies who claim to be well down the path to lean production!

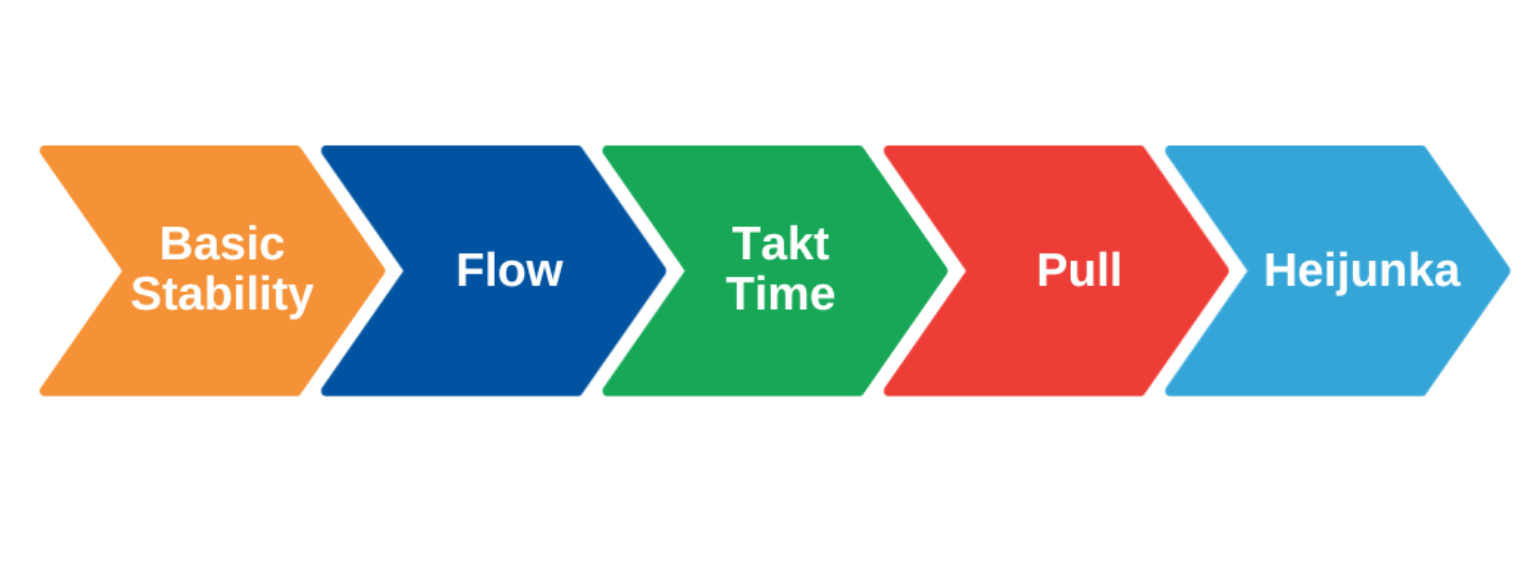

With operational availability this low, trying to introduce continuous flow by linking steps and connecting areas of flow with pull systems is certain to be an exercise in frustration. The only way these systems can work at all is with large buffers of work-in-process between each step and these inventories hinder further improvement by hiding problems. So I’ve been forced to conclude that a lot of us need to pay more attention to creating basic stability as we try to flow and pull.

(Let me hasten to add that this problem extends far beyond factory equipment. I recently made an appointment for a medical test and had to postpone it twice because the complex equipment wouldn’t work. And does anyone know how to maintain jet-ways at airports? I find on my travels that jet-way problems delay the arrival and de-boarding on about one flight in twenty. And how can one of those simple moving walks in airports ever breakdown? But I seem to stumble onto at least one unmoving walkway on every trip. And why can’t anyone keep our email server running? Poor operational availability is pervasive – and avoidable – in every aspect of our lives.)

Low operational availability traces to six types of problems:

- Downtime, when a process won’t run at all (also termed major breakdowns or major stoppages).

- Changeover time, to convert from one product to the next.

- Minor stoppages, of just a few seconds.

- Cycle time fluctuation, when a process takes longer than planned.

- Scrap, meaning some production is lost.

- Rework, in which parts must be run through the process again, reducing the time available for new parts.

All of these are bad and all should be reduced. But be careful to avoid simple calculations of equipment utilization that confuse availability with uptime. The former is always good: Equipment must be able to run when you need it. The latter can be good or bad: High utilization (uptime) to overproduce items not needed is one of the worst forms of waste. And reducing time lost to changeovers by producing bigger batches rather than by reducing setup times is a big mistake as well.

The most important point is that these problems don’t go away with a bit of random kaizen and they certainly don’t go away if firms are only practicing breakdown maintenance without identifying trends and determining root causes. They also appear quickly in new equipment (sometimes bought because the old equipment won’t run enough to meet demand) unless the equipment is very carefully designed from a maintainability standpoint and then systematically maintained.

The challenge is to create a rigorous maintenance process that involves everyone, gathers the appropriate data, discovers the root causes, and installs fixes so known problems don’t recur, and new problems are anticipated (for example, from predictable wear during the equipment’s life cycle).

With these measures in place, the lean goals of flow, pull, and leveled production are vastly easier to achieve. Even better, as basic stability is created, many firms will discover that they don’t have capacity constraints. Indeed, they may find that they have too much capacity rather than too little.

Best regards,

Jim

Jim Womack

Founder

Lean Enterprise Institute, Inc.

Lean Fundamentals Bundle

Improve productivity, enhance team collaboration, and streamline processes to create value and solve problems effectively.