Popularized by the founders of IDEO, David Kelly and Tim Brown, and the d.school at Stanford, Design Thinking is an approach for finding creative solutions to problems people and organizations face. I recently taught an interdisciplinary course on design thinking, which got me thinking about its implications for lean practice. Specifically, what can the lean practitioner learn from design thinking?

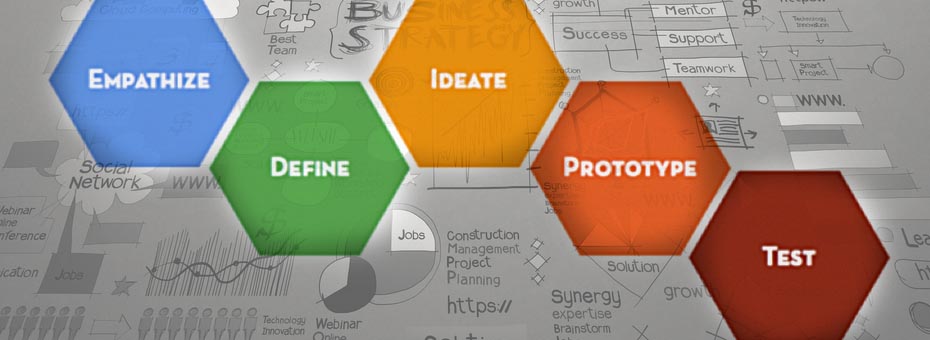

But first, a primer on Design Thinking. According to Tim Brown, “Design thinking is a human-centered approach that draws from the designer’s toolkit to integrate the needs of people, the possibilities of technology, and the requirements for business success.” In this approach, design teams iterate through various design modes to generate creative, workable solutions to real problems. Design thinking has gone through its own evolution, but one of the more popular versions identifies five design modes (See Stanford d.school’s Bootcamp Bootleg).

1. Empathize – engage with and/or observe actual users in the context of their environment. The aim is to deeply understand the people for whom we are designing, their needs, their problems, their concerns and what they value.

2. Define – synthesize the information collected into a focus or vision for the design exercise.

3. Ideate – generate a large quantity of ideas for addressing problem and different aspects thereof.

4. Prototype – move ideas from mental concoctions into the physical world so that the whole team can see how the idea might play out. The resolution of the prototype follows with the progress in the project. Early on, prototypes are very rough and rapid; later on, they become for sophisticated and “real.”

5. Test – refine ideas by placing the prototypes in the user context. The effect is often not just refining prototypes and solutions, but a deeper understanding of the user, new insights into the user context and/or needs which can lead to a reframing of the definition, more ideation, and so forth.

If you think about it, solving open-ended problems – where there is no closed-form solution and any number of countermeasures could work – is design. If we are working on process improvement, we are designing a new way of working. If we are implementing kanban, we are designing an inventory control system. If we are running a kaizen event to create single-piece flow in an operation, we are designing a new work cell. You get the idea.

So design thinking shares more than a little in common with lean problem-solving. The lean thinker is encouraged to go to the gemba, observe the problem first-hand in context, talk with operators, customers, and other affected stakeholders. This sounds a lot like the Empathize mode! From there, we pursue root cause to determine (or Define) the real problem. Once discovered, lean thinkers generate multiple alternatives to address the root causes (Ideate mode), and are encouraged to test them out using rapid PDCA cycles (Prototype and Test modes). We experiment first to test our hypotheses and refine solutions before moving towards full implementation.

Fundamentally, generating creating solutions to problems is a discovery process. Both design thinking and lean problem-solving recognize this, and have built in practices that aid in rapid, effective discovery learning. Whether it is understanding the issues through observation or immersion, or using low-fidelity physical prototypes to generate new ideas or test them out, or learning-by-doing, when you are trying to create something that has not been done before, there is a lot of learning and discovery needed in order to reach a successful conclusion.

You don’t have to look very far to see that lean problem-solving has a reputation of perfecting something that already exists, of slow and steady incremental improvement; and that if you want to be innovative you need something else. But in reality, lean problem-solving simply REQUIRES innovation because you are continually reinventing your systems and as we do this, we want to improve rapidly, not slowly. So, lean problem-solving and design thinking are, actually, incredibly compatible.

In fact, we can enhance lean problem-solving by incorporating design thinking tools to enhance the lean practitioner’s toolkit and help us be more creative in our efforts. Here are some examples:

- Design thinking uses a human-centered approach. The lean practitioner would do well to also take a human-centered approach to problem-solving so that their solutions work well for the humans involved, namely customers and operators. Design thinking offers useful techniques such as the “what-how-why” method, interviewing for empathy, and story share-and-capture which could lead to breakthrough innovations in process improvement.

- Design thinking offers a number of techniques to get at the heart of a problem; for example, the why-how laddering and user point-of-view. These techniques can give a lean practitioner an expanded set of tools for conducting root cause analysis.

- Design thinking presents a number of methods to stoke the creative generation of alternative solutions, which the lean practitioner can use to generate authentically innovative countermeasures while adding an element of fun to job.

- Design thinking has a bias towards action, and towards showing rather than telling. The lean practitioner, then, might be well-advised to try out their ideas through quick-and-dirty prototypes (rather than attempting to convince others through discussion and hand-waving).

- Design thinking is not a method or process. Even though there is a general flow, teams move between modes as they acquire new information, and iterate back to a previous mode as the needs of the project dictate. In a similar fashion, lean problem-solving may require returning to earlier stages of problem-solving to gather additional information or generate more ideas, etc.

So what do you think? What experiences have you had with design thinking? If you haven’t heard about design thinking, I encourage you to check it out. Maybe there’s potential here to give lean problem-solving a more innovative sheen; and connect lean practitioners and design thinkers to each other while we’re at it.