Imagine that the surgeon had sat around in medical school discussing heart surgery cases, watching heart-surgery videos, and listening to great heart surgeons talk about what they did—and now you are lying on the operating table, that surgeon’s first real patient. Would you let that surgeon cut into you?”1 This question was posed by Jeffrey Pfeffer, a professor at the Stanford Graduate Business School. And business schools are not the only ones with this problem.

Robert McMahan, PhD, the president of Kettering University, where students rotate semesters in the classroom and on the job, says, “If we taught musicians the way we teach engineers, they would get 12 years of music theory before ever touching an instrument.” Dr. McMahan is calling out the theory-based lecture, and “plug and chug” formulaic approach to engineering education employed by too many schools. This approach does little to prepare engineers for the challenges they will face in the real world or develop the grit required to be successful in uncertain and difficult environments.

If we taught musicians the way we teach engineers, they would get 12 years of music theory before ever touching an instrument.

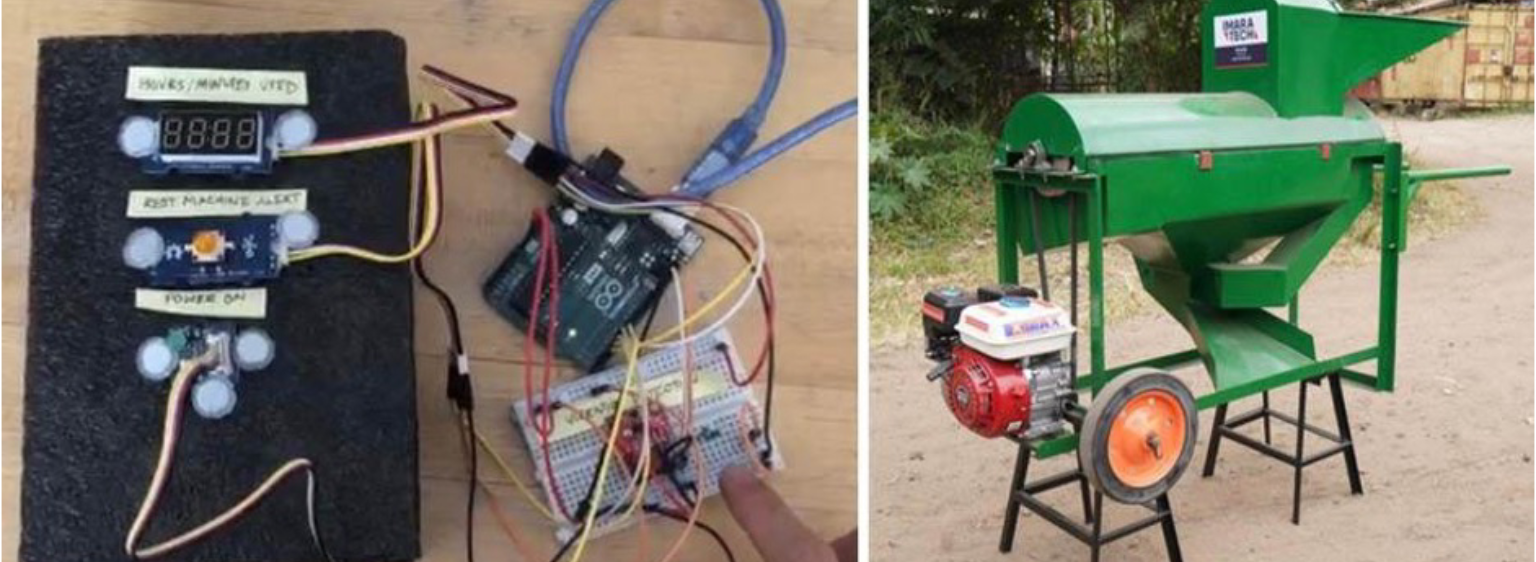

What has all this to do with MIT’s D-Lab and the unique contribution engineers make to solving critical social issues that we are celebrating in this issue of the Design Brief? Believe me, D-Lab’s work on behalf of underserved populations is nothing short of amazing. They have been able to focus the incredible problem-solving capability of engineering students on solving real-world problems for populations largely ignored by others. Whether it is the challenge of providing clean drinking water, improving the back-breaking work of coffee farmers in Tanzania, making charcoal briquettes from agricultural waste in Haiti, or developing and producing a life-changing, multi-grain thresher in Tanzania, D-Lab students solve difficult problems in novel environments and create life-changing value for their customers. But it’s difficult to determine who D-Lab’s work has the greatest impact on. They are certainly changing the lives of those they serve. But the skills and experiences that engineering students gain throughout their D-Lab experience are invaluable.

So, besides admiring D-Lab’s outcomes, I’m also a big fan of the way that they do it. Student engineers start by deeply understanding their customers in developing world environments. An environment with challenges often quite foreign to the engineering students. The experience stretches students’ problem-solving capabilities and exercises their innovation muscles as they work with their customers, often at the gemba, to create a bespoke solution. But they are not finished there. This isn’t just about creating a one-off prototype. The students need to think about the entire value stream: How will they scale up to production? How will they hit very challenging price targets? What will the supply chain look like? How can they build a viable business?

These are not theoretical exercises, but hands-on, roll up your sleeves work, and D-Lab spaces reflect that. 3D printers, CNC machines, welders, and other tools crowd workshops. In workshops, D-Lab engineering students manufacture their own prototypes to test hypotheses on various product solutions. Consequently, students emerge with a deeper, more visceral understanding of the products they are proposing. Combined with mentoring from industry-experienced people (how I was introduced to D-Lab) and studying their customer and context, students begin to understand what it takes to develop successful, value-creating products.

Such opportunities for hands-on innovation in challenging environments, solving problems that really matter while gaining critical skills that will last a lifetime. What better way to develop the next generation of engineers and designers? What an experience! “Transformative” is the most common description given by students.

Lest you think that I’m speaking from my own bias having come up in industry machining tools and welding and fabricating prototypes, I point to Toyota’s approach to developing young engineers which my coauthor, Jeff Liker, and I have written about extensively in The Toyota Product Development System and Designing the Future. It starts from the beginning with their freshman project and close work with an experienced mentor. New engineers are encouraged to work hands-on at the gemba where they can learn the most. It’s part of the very fabric of the Toyota engineering community. These values are passed on across generations in a myriad of ways, including the way they talk about developing engineers. I’ve heard several versions of this from the Toyota old timers, but one version goes like this: “Never trust an engineer who doesn’t have to wash their hands before they eat dinner.”

This isn’t just about creating a one-off prototype. The students need to think about the entire value stream …

So, who is D-Lab having the greatest impact on? That’s hard to say. But the engineers that I have met from their program are bright, passionate, caring, humans who want to (and know how to) wade in and make things better. Exactly the kind of engineers I want on my team. So maybe, just maybe, the biggest beneficiaries of D-Lab’s work are the companies who eventually hire these folks.

This issue of the Design Brief has been special for me. I have long admired D-Lab founder Amy Smith and her team. They are indeed remarkable. Cynthia Smith’s book Design for the Other 90% has long been an inspiration for me. I have given copies of it to young engineers to inspire them to use their skills to change the world for the better. So you can imagine what a treat it was to hear Lex Schroeder’s discussions with them. I hope you enjoyed them as much as I did.

What lessons to draw from this month’s Design Brief? Here is something you might consider: The products you create should have a positive impact on your customer’s life and the way you develop them should have a positive impact on your people. That’s how to make things better with lean in development.

Download the latest issue of The Design Brief

Accelerate Innovation and Optimize Product Development with LEI’s LPPD Consulting and Learning Group Collaboration

Transform your product development process with LEI’s Lean Product and Process Development (LPPD) coaching services. Our expert coaches help you design and deliver innovative products faster, reduce costs, and optimize workflows. Join the LPPD Learning Group to collaborate with leading companies, share insights, and learn from real-world experiences. Whether you’re just starting or looking to deepen your lean capabilities, LEI is here to guide your journey towards sustainable growth and competitive advantage.

Designing the Future

An Introduction to Lean Product and Process Development.