To help lean thinkers apply this powerful approach to overcoming work obstacles, LEI Senior Advisor John Shook guides lean thinkers through a detailed example from Taiichi Ohno’s Toyota Production System: Beyond Large-Scale Production. Find a transcript below.

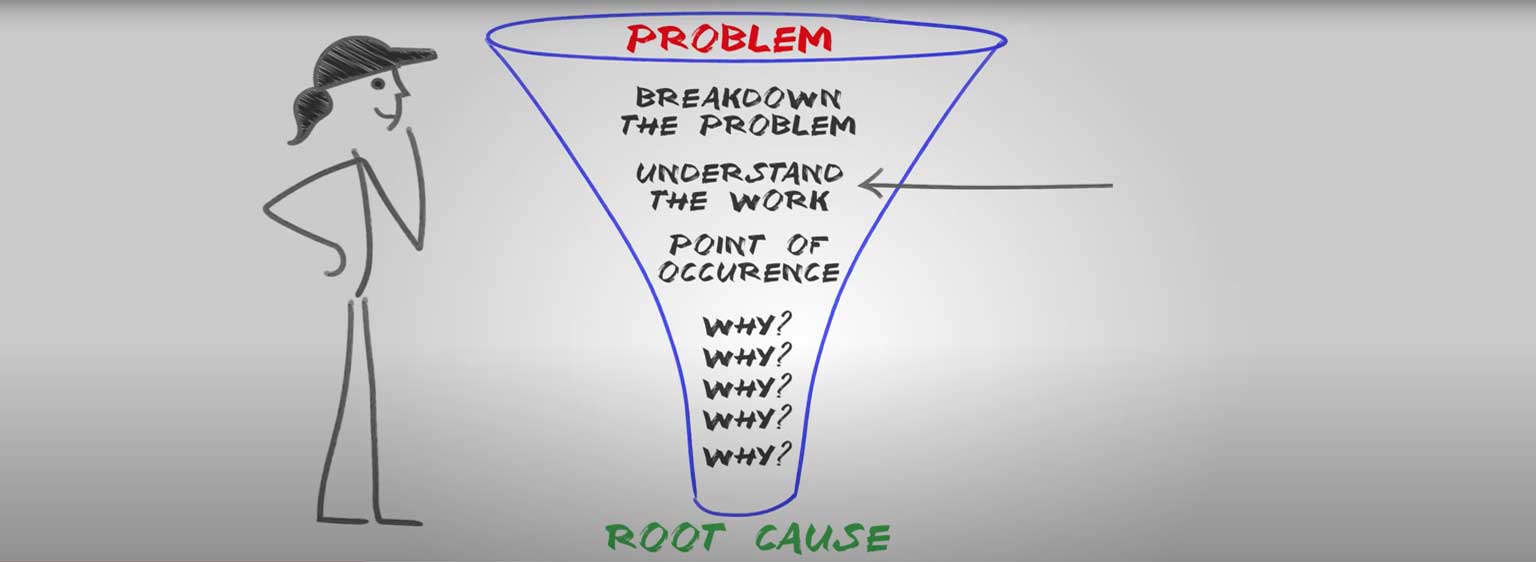

Let’s take a look at the problem-solving method known as the “five whys” or also “causal chains.” Let’s take a look first of all at how that relates to the problem-solving funnel as a frame where we began with a high-level problem—it might be something vague that we don’t fully understand, but it’s the problem coming at us on a day-to-day, moment-to-moment basis.

What we want to do is break the problem down to understand it, get some data, get some facts, and look for patterns. And from there, that means understanding the work, which is certainly a primary characteristic of lean problem-solving, which is to go and deeply observe and understand the work. From there, we can identify a point of occurrence, sometimes called the direct cause and also can be thought of as a problem on its own.

Now we can do the fun part, which is to start asking the five whys. We can put on our investigative hats and ask why, why, why is this occurring? That will lead us to a root cause regarding which we can attach a countermeasure.

To look at this part of the problem-solving process, the five whys or a causal chain, let’s look at the famous example from Taiichi Ohno of Toyota and the one he used starting in the 1950s of a machine breaking down.

The problem that he saw as the machine shop manager is that machines would often break down, and his people would often just attach a Band-Aid. They would only stop it at the first level of cause, meaning that the problems would recur; they would come back. So, he trained himself and his people then always to ask the five whys, sometimes three, sometimes eight, the point being to follow the causal chain all the way down to a root cause.

In this example, he looked at a machine that had stopped working and identified with the first why that it had blown a fuse in the control box because it was overloaded. The overload caused the fuse to blow. But, he didn’t stop there and asked why again, and recognized that insufficient lubrication was getting to the bearing. So, the bearing, therefore, was causing the overload on the machine.

Not stopping there, he went to the next cause and, asking why, found that the pump was not drawing lubricant. So, the lubricant, then, would not be sent to the bearing.

Still not stopping there. Why, again, was the pump not drawing lubricant? Because the shaft was worn, causing it to rattle and not function properly.

Now, another why there led him to a root cause, which was that there was no strainer, which allowed metal chips to enter and damage the pump. So, with the damaged shaft, that would mean the pump wasn’t drawing lubricant, so that there wasn’t enough lubrication going to the bearing, which overloaded the machine and blew a fuse, which stopped the machine from working.

So, he’s got a five-why causal chain going down to the root, and you can check that with the “therefore chain” going up as well.

Now he knows if he applies a countermeasure here, which is to make sure there’s a strainer, then the problem will be solved so that it doesn’t come back.

So, this is what you can accomplish with a fairly simple way of thinking so that we’re not just putting Band-Aids on symptoms—that we’re solving problems at the root cause.

Good luck with your problem-solving attempts.

Learn How to Identify and Solve Business Problems

- Gain a solid understanding of lean problem-solving by taking the on-demand, online course Intro to Problem-Solving. Learn more and register.

- Get an in-depth instruction and intensive coaching that will improve your—and your team’s—problem-solving capabilities. Join the next Managing to Learn Remotely workshop. Learn more and register.

Managing to Learn with the A3 Process

Learn how to solve problems and develop problem solvers.

Excellent, deep troubleshooting explained in detail and easy to understand. A concept well with the example.