The concept of double-loop learning was first introduced by Donald Schon & Chris Argyris in the early 1970s. After studying the behaviour of a large number of leaders from all sectors, how they interacted, and how this influenced office politics and performance, Schon and Argyris concluded that there are two different learning loops: single-loop learning (learning that confirms what we already think we know based on our current mental model) and double-loop learning (what happens when we challenge and change our mental model based on our learning experience).

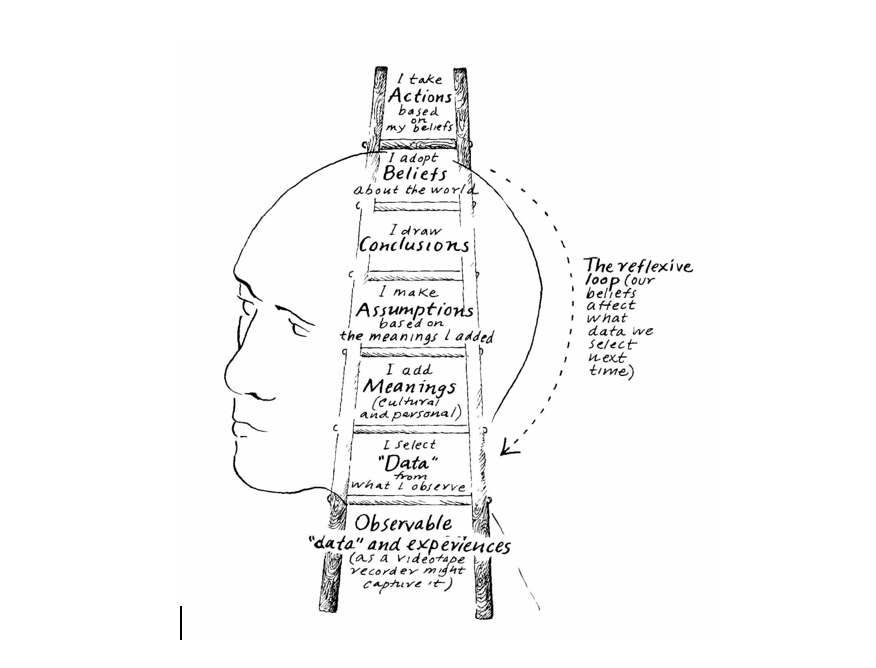

Argyris developed a model to visualise the thinking process that underlies single-loop learning that he called “The Ladder of Inference” (fig. 1). (There is a great chapter discussing this on pages 242-246 in the book The Fifth Discipline Fieldbook.) Our beliefs affect what data we choose to collect and what data we choose to ignore. We then add meaning to this data (ever wondered why some people see the same data as yourself and draws wildly different conclusions?). Then we make assumptions based on the meaning we have added, draw conclusions, adopt beliefs about the world, and finally take action based on our belief. We operate by unsurfaced and self-generating beliefs, reflexive loops which remain largely untested and over time become more embedded in thinking and practice.

“Most companies either struggle with improvement work in the support functions or just leave them alone altogether thinking, based on their beliefs and assumptions, that lean is only for improving production.”What Toyota discovered through practice was that the only way we as adults could effectively challenge our beliefs, and experience real learning, was the practice of gemba management and Genchi Gembutsu, supported by constant cycles of PDCA. In order to change the way you think about what you do, you need to practice PDCA on the gemba. Observe what is happening, challenge your beliefs through action, study the results and adopt the change or abandon it, or run through the cycle again. We believe that what Toyota discovered, and what has subsequently been discovered and re-discovered by lean thinkers around the world, is that as adults, we only really learn through experimentation. By visiting the gemba and challenging our thinking we learn how to act our way into a new way of thinking.

What does this look like on the gemba

Recently we had the opportunity to visit a small company in Norway that, after participating in a lean supplier development program (you can read about that here),are changing the way they think about what they do through a process of double-loop learning. Flaatnes Elektro-Mek. (FEM) is a small company situated on the south-east coast of Norway. Having always been a customer-focused company, a recent introduction to lean thinking and practice has further enabled the company to relish and embark on an unexpected growth strategy. Through our discussions with management and observations on the gemba, we discovered three examples of double-loop learning we would like to share.

The first example of double-loop learning that the company shared with us was how they had introduced visual work instructions and 3D-printed jigs to increase the quality of their products. As with most managers who embark on a lean journey the idea of visualising work for highly skilled operators seemed a waste of time. Previously, they were also somewhat skeptical about moving from complex production procedure manuals to simple one-point-lessons (OPL), as they feared they may lose sight of important technical information, and the assumption was that the operators know how to do the work anyhow. However, instead of just making the technical work manuals available at the work stations, what they discovered was that simple, visual work standards in the form of OPLs had a big impact with the operators. Not just with regards to quality, but also allowing the operators to engage in improving their work. This experience changed their thinking and they now see OPLs as one of the keys to continuous improvement, for example in driving the adoption of simple, 3D-printed work holding devices. The OPLs gives management and operators a shared “facts-sheet” to work from and make the underlying thinking behind how operations or products are designed easier to discuss and challenge through experimentation.

Most companies either struggle with improvement work in the support functions or just leave them alone altogether thinking, based on their beliefs and assumptions, that lean is only for improving production. So, another otherwise counter-intuitive decision they made was to focus on reducing waste in administrative work, constantly striving to remove trivial tasks that make admin. work a hassle. In close collaboration with their IT-system partner, FEM have simplified and improved their ERP system to the extent that the two-person management team can effortlessly complete all admin. work (HR, invoicing, payments etc.) while spending most of their time on sales, product development and supporting production staff. While working on improving the admin processes they also discovered that focusing their efforts here actually made a big impact on their competitiveness as this work has also reduced the overall cost of making products.

“Challenging our own mental models is hard work, and also something that most adults are not really prepared to do.”What also impressed us was how the company has altered its thinking with regard to planning and forecasting. In many companies, this is a cumbersome, once a year event that involves a lot of politics, wishful thinking and, of course, budgets. This was the case with Flaatnes as well. With the success of admin work improvements, why not just optimize the planning and forecasting process? Well, after being introduced to Hoshin Kanri and developing a very simple Hoshin plan for the company, FEM has eliminated the traditional planning and budgeting process and works solely with a few metrics such as safety, quality, delivery, and cost; in addition to expected and actual turnover and expected and actual profit margin. The Hoshin plan connects the company’s strategy with continuous improvement initiatives, and this information is available to all employees on the visual management board in the production department. However, the biggest impact for management was that getting rid of the yearly budget and instead using 3-year hoshin goals that break down into yearly targets made them both flexible and better at long-term thinking. According to the CEO and owner Lars Flaatnes, it gave them a much better overview of where they want to go and where they are today. With their hoshin strategy now on a single A3, it makes it easy for everyone from the board to employees to understand and relate to.

As a small company, FEM has not had to deal with the typical bureaucratic Big Company Disease that often start to creep into a company once it passes a certain size, usually a lot smaller than one would assume, and often in the region of 30 employees in our experience. Lars had actually never intended to grow the business larger than 10 employees, but recently broke his cardinal rule (FEM currently has 14 employees and are considering growing to 15). However, from participating in the lean supplier development programme and the subsequent deployment of lean thinking and practice, FEM are now prepared for sustainable lean growth with a means to structure their learning. Now, they are not only learning what they want to learn (learning is of course voluntary), they are in fact learning what they have to learn – about customers, technology, production and admin. processes, even their own supply network (after experiencing the impact the program has had on themselves, they decided to run a similar program with their own suppliers).

As owners, executives, managers or employees, we learn every day. Every experience is a learning experience. However, we tend to only experience single-loop learning. We reaffirm what we already think is true. We don´t change our mental model. Challenging our own mental models is hard work, and also something that most adults are not really prepared to do. However, there is no way around it if we want to support meaningful change in our organisations. What Taichii Ohno and other Toyota pioneers have shown us is an education system in lean thinking and practice that gives us a framework to challenge our beliefs and assumptions and create double-loop learning situations through concrete experiments, and often real-time feedback from the real world.