Following Four Steps to a Lean Material-Handling System Leads to a Leap in Performance

Companies pursuing a lean transformation often begin with cellularization, achieving dramatic and rapid improvements. But unless they replace the traditional material-handling systems supplying the cells, they jeopardize their ability to sustain the gains or advance to the next level of performance.

For instance, two focused factories at the Kokomo, IN, plant of Delphi Delco Electronics, realized these combined results by methodically implementing a lean material-handling system for its purchased parts:

Box score of Improvements from the Lean Material-Handling System

| Productivity | 20% increase |

| Work-in-Process (WIP) inventory (dollars) | 20% reduction |

| Ship window compliance | 99.9% |

| Premium shipments as a percent of shipments | .04% |

| First-time-through quality | 35% improvement |

| Purchased parts inventory (volume) | 18% reduction |

“We totally redid the supermarkets,” said Kathryn McCombs, plant operations manager. Four separate supermarkets holding purchased parts for four production areas were combined into one, which was positioned adjacent to the receiving dock. Finished goods, which had been stored in manufacturing areas for pickup once or twice a day, were moved to a finished goods supermarket adjacent to the shipping dock. “We also put in place time-based routes” to deliver purchased parts to cells and remove finished goods much more frequently, said McCombs.

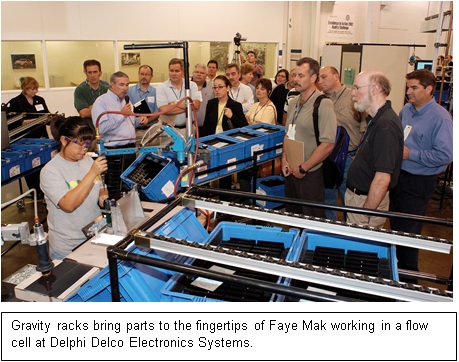

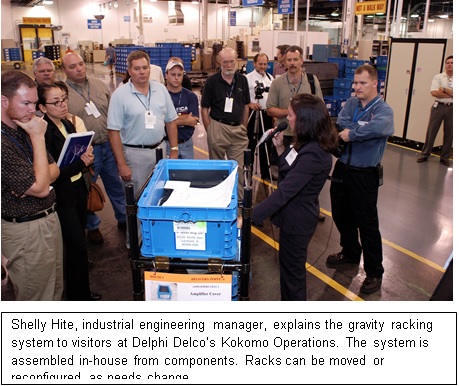

During a visit by LEI and members of the Lean Community, the operation and implementation of the material-handling system were explained during a tour of the markets, shipping and receiving areas, and a value stream making the main circuit boards for a range of audio products. The sprawling plant and division headquarters complex makes a variety of automotive electronics products, including circuit board assemblies for radios, integrated circuits, sensors, engine control modules, and climate controls.

The Old Days

Before implementing the new system, totes with purchased parts and pallets of finished goods clogged aisles and were stacked against nearby lockers, recalled Joe Huntzinger, audio area operations manager. “Now, parts come in by the pan and tote, and finished goods flow out in totes,” he said. “We only have the material that we need for the next 30 or 40 minutes.” Aisles and lockers are clear.

“It really, really, cleans up your production floor,” Huntzinger noted. “And when you get the floor cleaned up, it makes abnormal conditions obvious and reduces your reaction time, and you really see employee morale improve.”

From an operations viewpoint, a lean, reliable material-handling system delivers benefits beyond removing the clutter and cost of excessive line-side inventory. It means managers and supervisors “don’t have to worry about schedules or material anymore,” said Huntzinger. “We can concentrate on manufacturing issues to drive out more costs.” He estimated the new material system has freed “two to three hours” of his time daily.

What follows is a closer look at how the lean material-handling system operates and the progression of steps Kokomo Operations followed to implement it.

The three assembly cells in the audio value stream operated on a six-minute pitch with a standard pack quantity of 30 boards. (Every six minutes, a cell produces a finished goods tote containing 30 completed boards.)

Two separate tugger routes — one delivering purchased parts, the other removing finished goods — serviced the cells and others within the two focused factories.

Every 30 minutes, an electric tugger arrived pulling five carts with parts from a central market for purchased parts. Tucked into a metal bin on the lead cart was a clear plastic manifest packet from production control with pull cards and instructions for what models to build next.

The arriving manifest told assembly what part numbers to build, the components to use, and a relevant quality message, such as, “Make sure the wire is seated.” Each pull (withdrawal) card in the manifest packet instructed the assembly team leader to remove a specific canister of partially completed circuit boards from a work-in-process (WIP) market in a fabrication area adjacent to assembly.

When the leader removed a canister, she put the pull card into a pick-up box. It went back into fabrication, triggering the production of 30 more boards by automated surface-mount machines. Across the aisle in assembly, cell operators manually finished installing components on the boards, soldered and tested them, applied a shipping label to the finished goods tote, and slid it down a gravity rack to the outside of the cell for pick up. Each finished goods tote contained 30 completed boards.

The tugger driver uncoupled the carts in a marked space a few steps from the audio cells so that the team leader could walk over to get purchased parts for operators. (Improvement plans call for parts to be delivered to the fingertips of cell operators.) In an adjacent space were empty carts that had been dropped off full 30 minutes ago. After uncoupling the full carts, the driver hooked up to the train of empties for the trip back to the central market. A completed manifest was tucked into a “built manifest” box on the lead cart. At the market, the driver turned in the built manifest to trigger replenishment of the used parts. He uncoupled the empty carts in a marked space, then pulled up to a train of full carts alongside to resume the route.

Every 15 minutes, a finished goods tugger arrived at the assembly area. The driver quickly slid out full totes from the finished goods rack and slid in empty totes. Huntzinger pointed out that racks were arranged so the exchange of totes occurred on the outside perimeter of the cell. That way, cell operators weren’t interrupted. The tugger took the containers to the finished goods market in shipping.

Evolution of the New System

The current system corrected the shortcomings of earlier material handling systems. There used to be four purchased parts markets, one for each production area in the two focused factories. Material handlers used pushcarts to bring parts to cells. Tow motors picked up finished goods from production areas. In an improvement effort, the four markets were combined into one. But each production area had its own separate area within the market and its own group of material handlers to deliver parts and remove finished goods. Since routes from the central market were longer, material handlers traded in their pushcarts for tuggers.

In an effort to get better control over inventory and clear it from floors, Kokomo Operations began planning the current system with formation of a cross-functional group drawn from production control, industrial engineering, operations, shipping, quality, hourly employees, and safety representatives. The team’s objective was to develop and implement an overall vision and system for material handling.

One of its first steps was to draw a current-state map of the existing material-handling system and a future-state map of a much leaner one that would include a purchased parts market near receiving, a finished goods market near shipping, and small WIP markets at the points of manufacturing.

Implementation of the lean material-handling system followed four steps, which other companies can adapt to their environments, according to Rick Harris, president of Harris Lean Systems, Inc., and a Toyota veteran.

- Develop a Plan for Every Part (PFEP), a database that contains every part number entering the plant, its specifications, supplier, supplier location, storage points, points of use, and usage, along with other important information.

- Create a single purchased-parts market for all parts entering the plant and implement rules for managing the market.

- Establish precise delivery routes to move all materials within the plant, using standard work.

- Integrate the new material-handling system with the information management system through the use of pull signals to insure that only the parts that have been consumed by the cells will be replenished.

Following these steps creates not only a lean material-delivery system, but an inventory control system.

1. A PLAN FOR EVERY PART

The first step in creating a lean material-handling system was to thoroughly understand where every part came from, where it went, and how it was used. “You’ve got this information today in your plants. The problem is, it’s scattered all over the place,” said Harris. The PFEP centralized the data. It’s simply an electronic spreadsheet or database that contains all the critical information about parts. Kokomo Operations used this data to manage the material-handling system, size markets and storage racks, and design timed delivery routes.

Kokomo managers began with an Excel spreadsheet but migrated to an Access database to maintain better control over the data, explained Sergio Grimaldo, a Delphi Manufacturing System implementation manager. (The Delphi Manufacturing System is the company’s lean operating system.) Grimaldo, an industrial engineer, worked with Production Control as part of the cross-functional team effort that created the lean material-handling system.

He stressed that while all users had access to the PFEP, only one person, the PFEP manager, had authority to enter data in order to safeguard data integrity. The PFEP manager also authorizes requests to change data and challenges them, especially if they increase inventory. Users submit change requests on a standard form.

Amassing the information into a spreadsheet or database allowed data to be sorted by useful categories, such as supplier, usage, location, container size, etc. A typical PFEP database contains these categories:

- Description Daily Usage

- Point of Use Location Storage Location

- Standard Container Quantity Supplier Name

- Supplier City Supplier State

- Order Frequency Delivery Frequency

- Carrier Transit Time

- Container Type Length

- Width Height

- Weight

You’ll have to establish your own PFEP categories based on your business requirements. For instance, you might want to include cost per part, the minimum and maximum numbers of containers needed, and a rating of supplier reliability.

To make the job of populating the PFEP database more manageable, Kokomo Operations added data for one manufacturing cell at a time, beginning with the audio final assembly area, which was the pacemaker for the entire value stream. Then managers created the purchased parts market, pull signals, and tugger routes for the area. This way, people became familiar with how the database and system worked before extending them to other areas.

2. ESTABLISH THE PURCHASED-PARTS MARKET

The central market at Kokomo Operations holds a controlled amount of inventory for 4,506 purchased parts. Its location near the receiving dock permits quick delivery from receiving to storage racks. The major steps in designing the market were:

- figuring the maximum inventory level for each part;

- establishing rules for operating the market.

Figuring Maximum Inventory Levels

Using the data in the PFEP, Kokomo Operations calculated maximum inventory levels for each part in the assembly area with the formula:

Daily usage x shipment size (in days of production) + purchased parts buffer = maximum inventory level.

So, if daily usage were 2,000 pieces for a particular part and the shipment size is five days worth of production delivered once per week, the formula would look like: 2,000 x 5 = 10,000 parts + the buffer.

To determine the buffer, Kokomo managers weighed such factors as variations in usage, a supplier’s quality and on-time performances, distance, transportation reliability, and the risk of bad weather. In this example, if the buffer were 4,000 pieces, the maximum inventory level would be 14,000 pieces (10,000 + 4,000). Increasing the frequency of shipments reduces the maximum inventory levels.

The next step at Kokomo Operations was to determine the amount of market space required to hold the maximum levels for each part in the assembly cell, even though the maximums would rarely be reached. To do this, managers had to know how many containers of parts would be needed at the maximum levels. The formula is to divide the maximum inventory level (14,000 pieces) by the standard container quantity (found in the PFEP). If the standard quantity is 100, our example becomes 14,000 / 100 = 140. So, the market must be able to hold 140 containers of our example part.

Using the container dimensions from the PFEP for Kokomo Operations, managers calculated the physical storage dimensions of the racks, part by part. John Lipinski, market manager, said the information in the PFEP on the size of containers was crucial in designing the market’s layout and racks.

Market Operating Rules

With the market sized and built, these rules were established to operate it efficiently:

- The proper storage method was selected to hold parts. Companies usually need a mix such as gravity racks for smaller parts and pallet storage for large or heavy parts. Gravity racks for the market at Kokomo Operation were built in-house from a commercially available system that can be moved and reconfigured.

- An address system was developed for the market using letters and numbers to indicate what section a part is in and its exact place on a rack. (You’ll also need an address system for the plant, if you don’t have one already, to pinpoint the location of each cell.)

- Methods for placing and picking parts were created to maintain a first-in, first-out sequence. For example, parts are loaded from the rear of the flow racks and picked from the front.

- Procedures for reacting to too much inventory were introduced. So it wouldn’t wind up with too many parts in the market, Kokomo Operations wanted the procedures to signal when a supplier overshipped or a process used less than expected so corrective action could be taken quickly. It created an overflow area next to the market to hold the excess parts in plain view, thus calling attention to the problem. A board in the overflow area identifies the part, the problem, and the countermeasure being implemented.

- Procedures were also needed to signal when parts hit the minimum level needed to sustain operation without a stock out. This level was set at the point where there was still enough material on hand for the supplier to expedite the part in time to prevent a production shut down. Managers worked out the time needed to communicate the problem from a cell operator up the chain of authority to the production control manager, added in the time needed by the supplier to load a truck and get it to the plant, then added the time needed to get the part from the truck to the cell. The minimum level is not the reorder point, but rather an emergency point. If the material-handling system is working properly, it should reorder parts just before this level is reached. If parts hit the minimum level, it means there is a problem, such as a breakdown in reordering or an equipment failure at the supplier, that must be investigated and fixed.

3. ESTABLISH PRECISE DELIVER ROUTES

With a central market established, Kokomo Operations designed the routes to deliver parts to cells, starting with the audio assembly area and then rolling out the system to other areas. Here is the sequence of steps managers followed:

- First, they marked out one-way and two-way aisles for bringing parts to audio assembly and empty containers back to the market for refilling. Material delivery vehicles were permitted only in the aisles, which are off limits to material and people. This let material handlers adhere to schedules based on standard work.

- Then, they selected the vehicle to deliver parts and finished goods. Kokomo Operations picked tuggers because the facility is too big for pushcarts or bicycles. Tuggers are suited to delivering small quantities of good frequently while fork trucks are suited to move full pallets. In addition, tuggers are safer, more maneuverable, and less expensive than fork trucks, which are used only on the shipping and receiving docks.

- The next steps were to set clearly marked material delivery points and delivery stop points for the audio cell. The goal was to have the tugger stop (at the stop points) where the driver can conveniently deliver to several racks (the delivery points).

- Finally, with the stops and delivery points marked, it was time to build racks at the cells where the parts are used. Kokomo used gravity racks so tugger drivers could slide new containers of parts to the fingertips of operators inside the cells. Drivers fill the racks from the outside, so they don’t interrupt the working operators. Each part used in the cell has its own shelf. When a container is empty, the cell operator slides it down a return shelf for retrieval outside the cell. To figure out how many containers the racks should hold, Kokomo used a rule-of- thumb that shelves should hold twice the delivery-route volume of any given part plus one additional container of that part. So, if a tugger delivers an hour’s worth of container’s to a cell every hour, the rack needs space for one-hour’s worth of containers plus one container on the top shelves and space for one-hour’s worth of empty containers on the lower shelves. Based on experience, this method solves a potential space problem: Once in a while, the driver might arrive a few minutes early to find the cell operator working out of the last container. The shelf has to hold the container that the operator is using plus the hour’s worth of containers that the driver is delivering. If there isn’t enough room on a shelf to deliver parts, the driver places the containers on the floor, signaling management that there is a problem.

Determining the delivery frequency is a balancing act. Frequent deliveries mean there is less inventory (and less cost) in the system. They also mean more containers in the system and more work by route operators. Market attendants will also be busy transferring parts from large containers to smaller ones, unless suppliers agree to ship in smaller containers. A one-hour delivery frequency often strikes a happy medium between inventory costs and material handling costs. However, your circumstances might call for adjusting this principal. Managers at Kokomo Operations opted to start with a 15-minute finished goods route because of limited space for racks in the audio value stream area. In addition, a nearby value stream to be served by the route produced a skid of finished goods every 15 minutes. Thus, 15 minutes was a natural starting point for the route cycle time.

4. INTEGRATE THE MATERIAL AND INFORMATION MANAGEMENT SYSTEMS

Linking the material and information systems assures that only the parts consumed are replenished. In a lean material-handling system, this link is typically made by a pull signal, such as a kanban card, andon, or empty container. Kokomo Operations uses kanban cards. Production kanban cards trigger the fabrication of goods, but the cards used in the material-handling system are called withdrawal kanban because they authorize the movement of parts from the market to cells.

Kokomo also decided to use a decoupled delivery route, rather than a coupled route. In a coupled route, the tugger driver loads the tugger in the market and drives it to the cells. In a decoupled route, the work is divided between a market attendant who loads parts and the driver who delivers them. Decoupled routes require two sets of carts but they improve labor utilization, so routes can be longer and have more carts.

In Kokomo Operations’ decoupled route, market attendants loaded one train of carts while the other delivered parts. When the driver returned, he dropped off the carts carrying empty containers and the corresponding withdrawal cards, then hooked up the tugger to a waiting, loaded train of carts.

The type of route affects the number of kanban needed for each part. Coupled routes require kanban for three times the delivery frequency. Decoupled routes need signals for four times the delivery frequency. Coupled routes use a factor of three because they must allow enough time to cover (1) kanban on containers being delivered from the market, (2) kanban on parts containers already being stored at the cell, and (3) kanban from consumed containers that are being picked up at the cell. Decoupled routes use a factor of four because they must allow time for (1) kanban on containers being delivered from the market, (2) kanban on parts containers already being stored at the cell, and (3) kanban from consumed containers that are being picked up at the cell (4) kanban for the parts being replenished at the market.

To finish calculating the number of kanban needed, Kokomo managers had to know how many parts would be delivered on each delivery cycle and the standard quantity of parts to be delivered (from the PFEP). The formula for a decoupled route looks like this:

(Hourly parts usage expressed in containers) x 4x delivery frequency

————————————————————————————

Standard container quantity

The next job was to set the standard work for operating the route. Industrial engineers at Kokomo Operations used standard times, drawn from experience, to calculate the times needed to perform the standard work elements on the routes. For example, 2.5 miles per hour (or 3.66 feet per second) was used for the tugger speed, according to Shelly Hite, industrial engineering manager. The time allotted for the tugger driver to get off the tugger was 3.9 seconds. Removing a full container from a cart, walking to the rack, putting it on the rack, getting an empty container and pull signals was set at 7 seconds per container. Another 3.9 seconds was allotted for the driver to step back on the tugger.

Using these standards and the distance from the market to the audio cell, Kokomo engineers calculated the time to deliver one part number. Then they made the calculations for all the part numbers for the cell. The same process was followed for every cell on a route.

A standard work document was developed for the tugger driver, listing each stop, the required actions, part numbers delivered, the time allowed to complete the stop, and the drive time to get there. The drivers record any problems on the sheet. The tugger schedule is posted at each cell.

To support standard work and good ergonomics, a standard system for loading carts was developed to ease delivery to the cell racks. Parts are loaded on the carts by cell and the sequence of delivery points. Part numbers have specially marked spaces on the carts. Operators, materials handlers, and tugger drivers take lunch and breaks at the same time. This keeps the system in synch and gives technicians time to perform some maintenance on equipment during the lunch break.

Hite noted that after the route was designed, it was run for a week to debug it. During this time, engineers monitored performance, adherence to standard work, and got feedback from employees.

She said one of the hardest obstacles to implementing the new material-handling system was helping operators, who had been accustomed to having lots of parts around, adjust to the new method of working. For instance, some people, concerned about not having enough parts, turned in pull cards before using the corresponding parts in order to create buffers in their cells. But ordering more than the standard quantity threw off the standard work for the tugger driver and market attendants, which meant parts arrived late, which created more incentive to buffer. People had to learn to trust the system and follow the rules.

To sustain the system, supervisors perform daily written audits of the market, delivery route, and pull signals to make sure the system is operating properly. Experience shows that the best and most effective way to sustain the changes implemented during a lean transformation is through such daily auditing. Without it, management says, in effect, “It’s okay to disregard the standard practices we just put in place.”

For more information

With its world headquarters in Kokomo, IN, Delphi Delco Electronics Systems is a subsidiary of Delphi Corp. Delphi Delco Electronics Systems provides a full line of vehicle electronics including integrated body, chassis and safety, powertrain, and wireless and mobile multimedia electronics systems. The division employs 6,300 people at its administration, engineering, and manufacturing site in Kokomo. Delphi Delco Electronics employs approximately 30,000 people worldwide.

What an excellent post on the lean material handing system process – I enjoyed reading your 4 step walkthrough, thanks for sharing.