Be among the first to get the latest insights from LEI’s Lean Product and Process Development (LPPD) thought leaders and practitioners. This article was delivered to subscribers of The Design Brief, LEI’s newsletter devoted to improving organizations’ innovation capability. It is the third of five in a series on quality entitled “Whatever Happened to Quality First? Rethinking Product Development the Wake of Recalls and Catastrophic Failures.” Click to read the first and second articles.

Toyota’s quality, reliability, and durability are legendary. Toyota has dominated automotive quality measures for decades and perennially tops the lists of most highly recommended vehicles released by Consumer Reports, J.D. Power, and others. So, you can imagine our excitement to meet with one of the principal architects of Toyota’s vaunted quality system, Professor Tatsuhiko Yoshimura, PhD, and his colleague Hidetoshi Shimizu. This was a singular opportunity to deepen our understanding of the underpinnings of Toyota’s phenomenal quality record and how they might help other organizations improve their quality performance.

We met in a series of late-night Zoom meetings with the goal of more deeply understanding the history, principles, and application of the innovative mizenboushi method developed by Toyota for evaluating the vulnerability of new product designs to quality problems. Translated as “reliability problem prevention,” mizenboushi is sometimes given the shorthand of “GD3,” which succinctly and accurately sums it up as “good discussion, good dissection, good design.” For brevity and clarity, that’s what we’ll call it.

If you can solve problems and prevent their reoccurrence, why can’t you just prevent them from happening in the first place?

Akihiko Saito

Yoshimura’s development of GD3 changed the way engineers thought about quality problems and enabled them to anticipate and design out quality problems before they occur. Shimizu is a longtime practitioner of the methodology at Toyota and elsewhere.

Yoshimura focused on design and development quality throughout his engineering career in Toyota’s Chassis Engineering, Reliability Engineering, and Quality Engineering departments. After retiring from Toyota as a senior executive, General Motors recruited him to help lead a quality renaissance. Yoshimura is capping his storied career as a professor at Kyushu University and a frequent contributor to the Union of Japanese Scientists and Engineers (JUSE). He documented the quality method in his book Toyota Styled Mizenbushi Method – GD3 Preventative Measures – How to Prevent a Problem Before it Occurs (JUSE Press Ltd., Tokyo, 2002).

A brief history of GD3

The genesis of GD3 was a discussion between Yoshimura and his then-boss, Akihiko Saito. Yoshimura rightly felt pretty good about the reliability of Toyota vehicles and Engineering’s problem-solving and problem-recurrence prevention work. While Saito agreed, he was not satisfied. “If you can solve problems and prevent their reoccurrence, why can’t you just prevent them from happening in the first place?” A daunting assignment to be sure.

Yoshimura started this assignment with a “study period” to deeply understand the challenge before acting. He began by asking questions and researching existing quality methodologies. A colleague in supplier quality suggested he look at the Failure Mode and Effects Analysis (FMEA) tool that some of the Toyota suppliers used.

So, Yoshimura and a small team began to study the FMEA methodology. They were astounded in their first meeting when supplier engineers brought stacks of 40-to-50-page documents for their review. They spent long hours poring over them, working to understand them in detail. The team developed dozens of questions for the supplier engineers, but the engineers could not answer them. The more they discussed the documents, the clearer it became that the engineers did not really understand what was in them.

FMEA is a tool to explain that there is no problem and not a tool to uncover a problem through collaboration.

Professor Tatsuhiko Yoshimura, PhD

The supplier engineers explained that they reused previous FMEAs and updated them with a “cut-and-paste” exercise. From this work, Yoshimura concluded that the FMEAs, while useful, were largely based on previous problems and were no more effective than Toyota’s existing standards and checklists. He also intuitively understood that FMEA was too bureaucratic, insufficiently focused, and lacked the collaborative enablers he knew were needed. In Yoshimura’s words, “FMEA is a tool to explain that there is no problem and not a tool to uncover a problem through collaboration.” Worse, the way the supplier (and others) used the documents made them simply muda.

Yoshimura and the team were similarly disappointed in design for six sigma, QS 9000 auditing, and numerous other existing quality methodologies. Consequently, Yoshimura began to feel frustrated about this assignment. He was an engineer, not a fortune teller. How was he supposed to predict problems before they happened? He began to envy his former quality control team members, who were busy solving problems and making things better.

Learning from accident prevention

That’s when he decided to look beyond quality discipline to see what he could learn from alternative fields. One of the areas he studied was industrial accident prevention work and the way it approached risk. Specifically, he studied the work of William Herbert Heinrich and “Heinrich’s Law.” Based on his study of thousands of accidents, Heinrich determined that at least 95 percent of accidents are caused by unsafe behaviors. His resulting law states that for every accident that causes major injury, there were 29 accidents that caused minor injury, 300 accidents that caused no injuries, and before that thousands of risky behaviors. Imagine a tradesman accidentally dropping a hammer from the tenth story to the ground. While it injured no one on the way down, the accident had the potential to cause serious harm, and thus, it deserves a proactive response to prevent a major injury from happening in the future.

Yoshimura saw strong similarities between risk mitigation in safety and quality. Consequently, he started to think about new engineering behaviors, principles, and practices that could solve not just the relatively small number of evident problems but the much larger number of hidden problems lurking in product designs.

Understanding that quality is a function of discipline, Yoshimura modeled the behavior of his most successful engineers. They would call attention to the smallest issues. They understood acting on the 300 hidden problems was far better than reacting to one catastrophe.

He also studied the Toyota Production System. He was inspired by such system practices as working on the process and process inputs instead of just measuring outcomes, making problems visible early in the process, pursuing root causes of problems, studying problems by going to where they occur, and most of all, its unwavering focus on the customer. All these lessons influenced his thinking about GD3.

With these influences in mind, he went to work experimenting with concepts and practices derived from what he had learned.

The three elements of GD3

Good design emphasizes creating robust designs by reusing proven components and proven design characteristics wherever possible. It captures critical characteristics from both successful designs and the most successful designers to minimize risk. It is equally important to learn from previous failures and less successful design practices and share those lessons. It also focuses on limiting the amount and severity of changes that impact a single subsystem. Finally, product features are designed such that they will make a budding problem apparent as early as possible, like a smoke detector chirping when the battery gets low.

Good discussion drives cross-functional analysis and debate, especially focused on any new features, new parts, new environments, and all critical interfaces. The discussion should be wide-ranging. The goal is to create an environment in your design reviews that promotes exposing problems and collaborating on solutions instead of hiding or denying potential problems. The specific forum for this debate is referred to as design review based on failure mode (DRBFM) and prioritizes areas of potential risk. Yoshimura claims that this process is more robust and efficient than traditional FMEA because it is a more focused approach; it concentrates on the areas of greatest risk.

Good dissection is a method for analyzing test results that starts with an extremely detailed review of any signs of unacceptable or inconsistent performance during testing. Parts from completed tests are dissected and closely studied for any signs of wear or degradation that might signal a potential weakness in design. Yoshimura also introduced a tool to help enable this process, called “design review based on test results (DRBTR),” which enables debate and captures learning to further strengthen the GD3 system.

The social side of GD3

Critically, GD3 is equal parts technical and social. Yoshimura explains that the first step to successful problem identification is to map a hierarchy of systems, subsystems, and components along with their corresponding organizations. This is to ensure the team knows precisely with whom to communicate. This can become especially challenging when a complex product requires multiple systems staffed by different teams to interact with one another. So, it is important to align around responsibilities.

When combined with an exclusive focus on areas of change, GD3 enables creativity to solve latent problems. Rather than being overwhelmed by an endless list of potential risks across systems and components, a team can focus its energy only on components undergoing change.

Design review based on failure mode (DRBFM)

We have often written about the importance of effective design reviews before and provided some principles and practices to improve them. Yoshimura agrees with the importance of design reviews and suggests that they are the perfect forum to introduce creative GD3. He provides some structure for introducing the GD3 method to a design review, starting with a basic process outline.

While Yoshimura did not find what he was looking for in FMEA methodology, he did appreciate the idea of a worksheet to aid in the discovery of budding problems. However, he rejected what he considered the tedious, mechanistic approach of FMEA for a more creative approach. He emphasizes that the entire approach is designed to stimulate participants’ creativity. The tools’ simplicity belies the terrific collaborative analysis underpinning them (examples follow).

As with all things lean, tools only work when combined with people and processes. For example, the point of an A3 is not to complete a series of boxes. The aim is twofold:

- To visualize thinking so management can provide effective coaching to develop the A3 owner’s problem-solving capability; and

- To socialize a problem across an organization to deepen understanding and alignment around countermeasures to ensure its permanent elimination.

The piece of paper is incidental, though its 11×17 size forces clarity.

Similarly, completing the matrices and question sequences used in GD3 is hardly indicative of effectiveness. What matters is the conversations and analysis that go into completing them. Individuals do not achieve quality through submitting paperwork; teams achieve quality through obsessive collaboration, investigation, and action.

The goal, Yoshimura notes, is to find latent problems in designs and take specific measures, correct them, and improve design quality. To that end, he created the following process and worksheet:

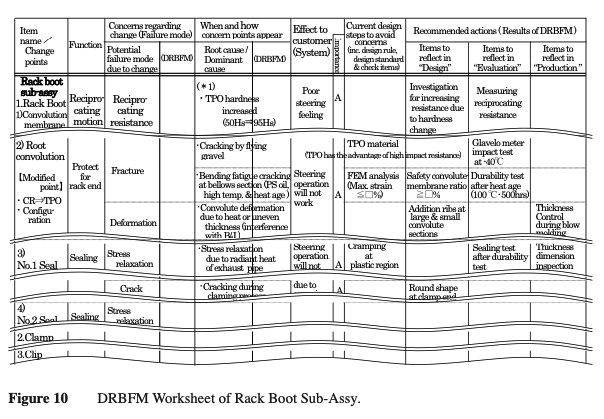

This table is a detailed breakdown from a DRBFM analysis for a rack boot subassembly. It illustrates a structured approach to identifying and addressing potential failure modes in the product’s design by examining changes at various points. Each item under review is analyzed for its function, potential failure modes due to change, and the corresponding effects on the customer. It also suggests design, evaluation, and production measures to mitigate these risks, illustrating a proactive step towards quality and reliability in product development. The table is the product of a cross-functional team’s creative exploration of a design’s vulnerabilities. To learn more, we suggest reading the journal article “Design Review Based on Failure Mode to Visualize Reliability Problems in the Development Stage of Mechanical Products.”

Design reviews based on test results (DRBTR)

DRBTR is part of good dissection. It is like DRBFM except that while DRBFM supports broad, cross-functional, and wide-ranging discussions, DRBTR is more focused, detailed, and based on testing and simulation results. It also occurs later in the development process for obvious reasons. In his book, Yoshimura provides the following questions as a general guide to assist in this process:

- As a result of your observations, what symptoms have you noticed?

- What problems might arise from these symptoms?

- What other symptoms are present?

- Under what situation will the symptom occur as a problem?

- What effects could it have on the customer?

- What measures have you taken to prevent the symptom from becoming a problem?

- Can this symptom manifest in any other area of the product as a problem?

- What measures have you taken for that?

- What problems can the group think of that might occur because of this symptom?

- Under what situation?

- Are there other possible problems?

- What measures does the group recommend?

Yoshimura provides some advice on computer simulation results. While simulation is fast and enables you to test many variables, do not neglect the value of actual physical testing. In particular, do not neglect testing to failure, as merely testing to specification does not provide a complete understanding of the limits of your product. Finally, like DRBFM, DRBTR should be done at the gemba (where work is done) whenever possible. The group should be able to see symptoms and results for themselves.

Some suggestions for success in design reviews based on failure mode

Preparation is critical. In his book, Yoshimura provides details on good preparation, including:

- Product or product computer-aided design (CAD) models;

- All contextual information, relevant standards, and best practices;

- Customer and environmental information;

- Relevant manufacturing processes

It is also critical to have the people with the best knowledge and experience in attendance. Finally, it is helpful to involve a facilitator or coach who has experience with DRBFM.

Four steps to get started with GD3

Successful implementation of the GD3 method and improved quality in product development starts with leaders and the culture they create. Quality, including meeting customer expectations, must be a demonstrated priority from the CEO down. Without the right quality mindset, recognizing that even small design changes can produce big problems without the proper intervention, GD3 will fail. Leadership must obsessively focus on customer value, drive attention to process improvement versus relying on correction, create an environment where problems are welcomed versus feared, demonstrate humility and a desire to learn, and give responsibility to process owners closest to problems.

Yoshimura notes, for example, that GM had better tools, but Toyota had a better quality mindset and that the mindset was more important. That said, he suggests four steps to experiment with GD3 in your organization:

- Reinvigorate your design review process;

- Identify a specific pilot project to experiment on;

- Train all those who will participate in the pilot;

- Select a facilitator or reviewer who knows the product or subsystem well, is a proven, adept problem solver, and understands and supports the GD3 method.

Introduce GD3 at a design review by asking these questions:

- What is new or changed?

- What concerns you about the change?

- What other related areas of the system have changed?

- What concerns do others have about this?

- What other concerns do you have?

- What impact will it have on the customer?

- What measures you have already taken to ensure your concerns do not become reality?

- What other measures can we take to ensure this down not impact the customer?

Conclusion

Toyota’s consistently high-quality performance has been unmatched for more than 20 years. It is amazing, especially when you consider the complexity of their product and the diversity of their customers. Obviously, GD3 is not the only reason for this. But it has been a significant factor. We think that it effectively demonstrates their relentless commitment to their customer, starting in development. Even when their quality and reliability led the industry, they were still looking for ways to get better. For us, this is the most important part of this story.

We realize that this article alone is not enough for you to become a GD3 practitioner. And perhaps the specific practices are not appropriate for your circumstances. That’s okay. We can only ask that you, in the words of Bruce Lee, “Adapt what is useful, reject what is useless, and add what is specifically your own.”

What matters most is that you create a culture of transparency and rigor. An organization that attacks problems, not people. Attacking people is the surest way to guarantee quality issues will go into stealth mode. And hiding problems is the surest way to a quality crisis. Leadership must create an environment that seeks out problems – big and small – giving teams not only permission but the responsibility to raise issues.

We urge you to start your own journey to improve your quality. If you are already good at problem-solving and recurrence prevention, move to preventative quality. Research your options. Try some experiments. Don’t be satisfied – keep pushing forward, focusing on your customer. Practice, practice, practice. By doing this you are almost certain to create what Professor Yoshimura referred to as the most potent quality attribute – a quality-first and customer-first mindset.

Good luck.

Download the latest issue of the Design Brief.

Designing the Future

An Introduction to Lean Product and Process Development.

Thank you for a spectacular insights, I think the culture to adopt this kind of knowledge must strive to excellence, sometimes the reactive culture wants quick results and I share sometimes their thinking because we need to invoice products, if we not invoice units we could run off bussines.