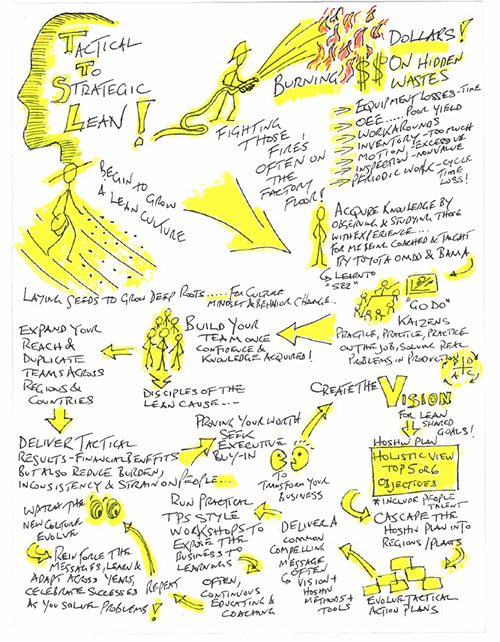

In my most recent article, I explored ways to make your work ‘work’ in the first 90 days. Specifically, I suggested that you grow from a tactical thinker to strategic lean player—which raises the question: How do you transform from being a tactical firefighter to a farmer who will growth and cultivate a lean organization?

I am fortunate to have lived, seen and experienced both these paths from my many years working in the automotive sector in my former roles working in continuous improvement. The focus was on hitting the numbers and then squeezing the dollars savings right now. Being heroic lean ‘fire fighters’ was very much the name of the game. It was all about tactical delivery, every minute of the day. The nature of beast was high volume production and assembly, with the lowest cost and best quality, in a safe way.

I lived this life for many years as a tier supplier and lean practitioner who transitioned from a quality management role into a lean/six sigma black belt position. As I worked my way up, moving gradually from being coached to coaching others, I shifted from the tactical to the more strategic approach. I began to focus on how to make a cultural impact across multiple plants in multiple locations and with people working in very different geographical cultures.

This meant nurturing that behavioral shift with the associated soft skills complemented by hard tools to make continuous improvement work naturally occur beyond just an event. This required me to act and think differently from my traditional comfort zone of a tactical way of operating.

I eventually decided to start with the elements of the Toyota playbook that would work with the existing culture in my business. I did not however do a simple cut and paste, but learned instead to be selective in adapting the precise mix of tools, techniques and approaches. These elements helped complement regional differences I found in the business. My objective always was to nurture and make a lean culture work and take root in my organization.

I had been working with Toyota as a supplier for many years, had often partnered with them, and understood how their approaches to viewing and solving problems would help, if I could translate this work ethic to suit our culture. I felt confident about taking, shaping and making their shared learning into a more specific formula to fit within my business environment and begin to nurture the culture shift.

As a starting point, I partnered closely with the top executive in charge of operations, someone who shared my beliefs. We targeted shifting the company culture to one with complete support and buy-in of the top executives (without which the work will be undermined and bound to eventually fail.) Shifting, adapting and changing culture is a multi-year endeavor. We spent more than five years sowing the seeds that grew into deep roots within the business. This included forming a multi-year hoshin plan at the executive level with just five to six top objectives defined. This cascaded down to regional and plant specific hoshin plans, each of which had many actions and key results that were tied back up to the top-level plan. We always focused on culture (developing people development and talent pipelines), building individual and team capacities.

We adapted a lot of content from a very success program that I had taken and then taught many times with BAMA, the TPS for Executives program, this modified version for our business drove a cultural shift, because it was a way of aligning many levels in our business to pull in one direction. We got the strategic vision and message out, and identified hidden talent from within the organization, as these perpetual actives run in a compressed dynamic and exciting workshop setting where the results we saw through use of the tools and methods exposed motivated team team leaders.

People inherently resist change, which is why culture is so hard to change. They don’t like being pushed out of their comfort zone. Through working the strategic side, I have found that you have to suggest a better alternative, and then put people in a setting where they can see the gains to be harvested if they take that step towards that change. And you show them that by collaborating with others in the organization for a greater good they can deliver greater results.

Can I say I moved the needle? Yes. Was it easy? No. But it was certainly exciting, challenging and impactful, and I think this hard work helped the business become more of a learning organization with a greater capacity for people to solve problems.

For those of you who would like to learn more about the tactical verse Strategic traits of a lean leader please check out the link to my video Scribe https://sho.co/1D33F