I try really hard to practice what I teach. One of the key concepts of lean transformation is the repetition of continuous improvement cycle. As many already know, without standards there can’t actually be continuous improvement (how do you know what you’re improving upon?) so you must have a baseline standard to measure your successful practices.

I remind you (and myself) of this because I’ve actually practiced some continuous improvement thinking in how I teach and explain lean concepts across industries and in my writing. Lean concepts can be difficult to explain in a one or two day workshops sessions or short articles, which is why it’s important to track how well I am doing.

Often I feel my clients and readers “evolve” me in a way that encourages me think through what their needs are in order to learn a concept better or translate it in their particular industry.

If you recall, last year I wrote a column referencing GTS4. It was a popular column so I felt a need to further develop it. In “try kaizen” fashion I have attempted to build upon and improve my thinking here. I have to admit, it looks a bit like algebra, but it’s a new and improved way to learn the highlights of leadership standardized work. It can be successful if practiced daily.

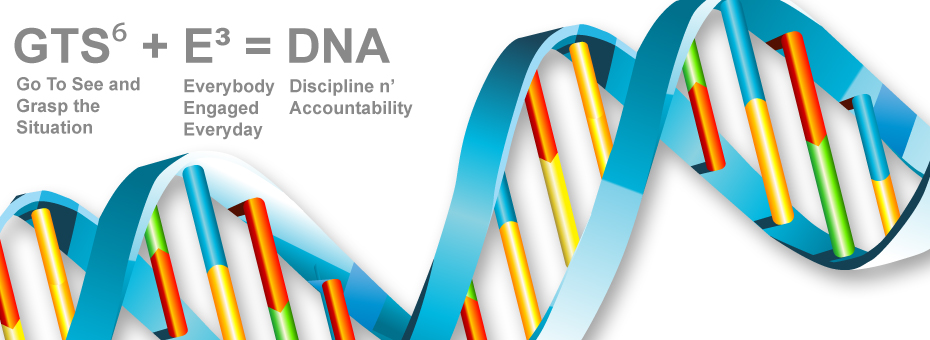

Let’s take a look and breakdown GTS6 + E3 = DNA.

First, let’s review what we learned last year and see how it’s been enhanced to complete the cycle of PDCA (plan, do, check, act):

GTS6

- Go to See

- Grasp the Situation

a. What is Ideal State?

b. What is Current State?

c. What is measurable gap? - Get to Solution

- Get to Standard

- Get to Sustainability

- Get to Stretch (goal – new standard)

This sequential thinking process not only takes you through problem solving, but it takes you around the continuous improvement “kanri cycle” of defining a standard through problem solving and working to continue raising the bar to the next level.

In between you see questions that leaders should be asking themselves and their team members at the gemba, involving and engaging people in dialogue about what should be, what is actually happening, and how to measure the difference. These questions encourage leaders to be present, giving them real actions they can practice (as well as replicate by teaching to others).

E3

Everybody Engaged Every-day in problem solving and continuous improvement. As a leader and a coach, whatever level you are in the organization, this is what you want to focus on and encourage in others. This creates actions and habits that give people a line of sight to how they’re contributing to the company, its true north and business goals.

Put these things together and what does this create?

DNA

Or rather, Discipline n’ Accountability. Both are necessary for any organizational culture to progress. And not just progress in any fashion, but progress in such a way that again, the organization is building and improving upon standards. People often ask me, how did you do it every day at Toyota? My answer is always some version of the equation above.

We had an infrastructure in place that required us to practice GTS6 by all levels and functional areas (silos), so everyone was engaged every day and we all knew the expectations. If you didn’t follow the standard, there was a possibility you could have a conference with Human Resources.

I often use the example of our strict attendance policy. So our shift start was 6:30 a.m. and the assembly line started to move at that time. With our production takt time being 57 seconds per car (meaning a car was produced off the line every 57 seconds), if you were 30 seconds late to your job (process) then you were considered “late.” Why so rigid you may ask? Well, in an organization that relies upon teamwork, it makes it a little more difficult to run the line if people aren’t in their appointed positions. A team leader (line supervisor) would have to take their place which often shifted the group leader to cover the team leader role and so on. So attendance is very important not just for the team, but holistically, for the company to learn and improve.

Our managers recognized the strict standard, but at the TMMK plant there was also a flipside to the rigidity, a little incentive if you will. If you attained perfect attendance (specific criteria) at the TMMK plant, you had your name placed in a bin and every year they drew 15 names for 15 cars (different model mix: Camry, Avalon, Venza) to be given out as a reward for having perfect attendance. It’s a great program, it generates tons of morale, and it always brings out some friendly competition among workers. During my time at TMMK I had several years of perfect attendance before moving into a salary role. (It was a great “edge-of-your-seat” feeling to think you may get a set of keys handed to you for coming to work every day on time!)

Does this GTS6 + E3 = DNA equation for lean leadership solve every problem for your organization? No. But it does describe at a high level of all actions leaders must take if they want to support a long-term, sustainable culture of problem solving. A culture where people feel empowered to make a difference for their organization and have a stake in the company’s overall success.

Job security = problems solved.