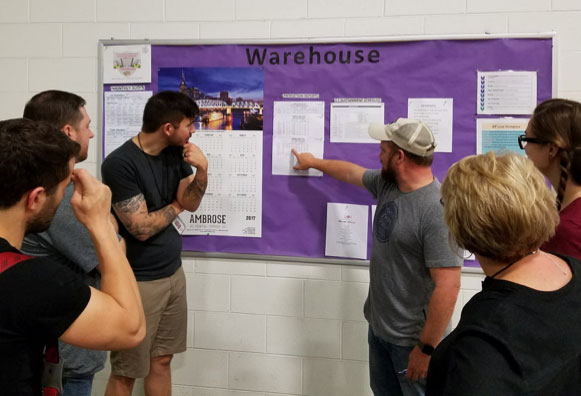

At the LifeWay Christian Resources distribution center in Lebanon, TN, General Manager Rodney Cathey concludes the morning meeting once or twice a week by asking the department heads and area supervisors for prayer requests. When we visited, the leadership team prayed for a 40-year employee struggling with diabetes, and another individual’s mother who was in the hospital.

LifeWay at a Glance

|

“Respect for people,” one of the lean management philosophy’s core tenets, can be one of those ideas that it’s easy to say but gets lost in the day-to-day pressures of running a business. The daily staff check-in and prayer is just one example of how LifeWay demonstrates what true respect for people looks like in daily practice.

The turning point at the LifeWay Distribution Center happened in 2011 with a change in management. That’s when the organization moved away from a top-down, tool-oriented approach to process improvement and toward a deeper, cultural focus on engaging and developing people. This story is about how this mission-driven, Christian organization has embraced lean and lean leadership practices, and what they’ve learned along the way.

Spreading the Gospel

By outward appearances LifeWay’s Lebanon facility looks like many other DCs. It’s orderly, well-lit and bustling with activity on a weekday morning. In addition to keeping the company’s 170 retail outlets stocked with merchandise, the distribution center supplies books, Bible School material, clothing, gifts and a wide variety of other Christian-themed products directly to mass retailers, congregations and individuals.

The 350,000-sq.ft. building houses a growing inventory of roughly 18,000 SKUs. The people there handled 2.1 million shipments in 2016. Incoming shipments arrive at the DC’s receiving docks and are placed in pallet racks 22-ft. high with 20,000 storage slots. Full cases are pulled as needed from the pallets and moved to shelving and flow racks in the loose pick area and pick-to-light cells. After workers pick and pack each order, the sealed and labeled boxes move by conveyor to the shipping dock for palletizing before being loaded onto trucks.

Screens in each department display the day’s workload and current status. In the picking and packing area, these screens show the orders and lines that need to be picked. These orders slowly disappear from the screen as they’re completed. Picking waves, which allow site managers to efficiently sequence and assign the work, are color-coded on the screens with corresponding plastic cones on each of the pick carts.

“The colors make it so the order packers don’t have to ask any questions about what they have to do next,” says Nicole Hudson, the site’s Manager of Continuous Improvement, who has worked in Lebanon for 17 years. “They know exactly what to do, which saves quite a bit of time.”

Touring the facility, one gets the feeling that new technology is embraced when it makes clear financial sense. There is some process automation, but there aren’t any automated storage and retrieval systems or robotic pallet-builders. Workers wearing headsets follow voice instructions to pick orders and place each item into blue bins on wheeled carts. The pick-to-light system is used primarily for mixed shipments of printed, time-sensitive material for churches.

Third Time’s a Charm

The history of lean at LifeWay is littered with stories of false starts and setbacks. Institutional memory is long and past management efforts that failed to bear fruit always make it harder for employees to engage with the next initiative.

LifeWay formerly launched its continuous improvement program back in 2002. The effort consisted mostly of variation reduction tools and slogans. They had a dedicated continuous improvement (CI) team but managers didn’t really understand the employee buy-in and cultural development required to implement improvements that would be sustained.

All in all, it was a frustrating learning experience on what not to do.

After several years the CI team began to take a more direct role and started implementing changes themselves. They neglected to engage people or empower them to improve their work areas, which was the primary reason why this second effort eventually fizzled out. Still, during this phase, they did accomplish several goals, such as documenting the key warehouse processes – how orders are picked, how they are packed and shipped – which established the future foundation for standard work.

Managers tried again in 2010 after they had worked out the kinks of a new warehouse management system (WMS). This time the CI team was able to implement and sustain a moderately effective 5S program, but it didn’t have much of an impact on daily performance.

“All in all, it was a frustrating learning experience on what not to do,” recalls Hudson. According to multiple reports, the limiting factor in all of these early CI efforts was a traditional management style that expected people to do what they were told.

It wasn’t until 2011, following some management turnover, that things began to change. Rather than being driven by top-down mandates, the CI team’s focus changed to developing everyone’s problem-solving capabilities. That started with two months of in-depth training around 5S (plus a sixth S for safety). Some of this knowledge was then applied to the redesign of the operation’s packing stations, for which they solicited employee input.

“Whether it’s picking or packing, whoever does that job every day knows it better than anybody else. We went down and got their ideas and suggestions on what made sense to them,” says Hudson.

Part of a cross-training initiative, the objective was for people to be able to move around throughout the facility based on the current workload. Previously, they had been mostly confined to assembly, order picking, or packing for their entire shift. Uniform packing stations would make it easier for anyone to step in and get right to work.

Listening to employees and incorporating their feedback into the new packing stations marked a turning point and the beginning of a real culture change at the LifeWay DC. Supervisors, who can be the most difficult converts, started to buy into the change effort because the problems that they’d been managing around for years were finally being addressed. As a result, their people were complaining a lot less.

Training, Training, and More Training

One of the often-repeated fringe benefits of a lean initiative is that everyone starts speaking the same language. Managers and associates begin to understand and share a focus on what matters most, and they have a common process for talking about and addressing any issues that arise. Training is where this language consistency and common understanding starts.

We looked at what we had learned from LeanCor, and started matching it up with the Bible.

As part of its renewal effort, in 2011 members of the LifeWay CI team started attending a lean supply chain professional certification program organized by LeanCor and the Georgia Tech Supply Chain &Logistics Institute. The program focused on problem solving and leadership in a supply chain context. LeanCor also delivered a three-day training course in Lebanon customized to LifeWay’s business.

“The LifeWay people went back to their facility in Tennessee and they immediately started to implement what they had learned,” says Ana Bailey, director of Consulting Services at LeanCor. “But they didn’t just go and start implementing tools. They really took the time to understand and talk to their team about how they were going to deploy lean within their distribution center.”

That conversation revolved around training. For training to be effective it has to engage and resonate with people. Ideally, the language should reflect the culture of the organization. To adapt the lean tools and methodology to their culture, LifeWay turned to their common source of understanding and inspiration.

“We looked at what we had learned from LeanCor, and started matching it up with the Bible,” explains Amanda Plumlee, CI team Lead. “There are several areas where lean concepts are very biblical. It’s really relevant with God’s word, especially when it comes to people and stewardship.” Stewardship – taking care of what God has given all of us – is one of the company’s core corporate values. After studying the eight forms of waste in such a context, figuring out ways to eliminate them was a natural thing to do.

The LifeWay CI team itself consists of five people. They developed all of the lean training material used in Lebanon, which they deliver to site leaders, supervisors, and employees. All employees must complete at least 10 hours of training per year. Leads must complete 20 hours and site managers are expected to complete 40 hours. In addition to the eight wastes, the scripture-based training programs have focused on process documentation, standardization, brainstorming, value stream mapping, and many other topics. (See sidebar, “Lean Problem Solving, with Nehemiah.”)

“In the past we weren’t doing nearly as much training on a regular basis,” says Plumlee. “It’s now about much more than 5S and making the warehouse look nice and neat. Pulling on biblical principles, the training is about how we treat our people, servant leadership, and how we grow as a company. By aligning what we do at work and what we do as Christians, everyone can really get behind it.”

Outside of the DC, the CI team has trained and worked with LifeWay’s corporate IT and procurement teams, helping them document their processes and eliminate wasteful steps. They also visited the back rooms of their retail store customers to observe the receiving processes.

Seeing how some shipments were damaged in transit to the stores led to changes in how products are packed and palletized. To speed up the receiving process they also started printing and including the price and shelf location stickers inside each shipment, which eliminated some work for store associates.

Just A Little Friendly (and Fun) Competition

In 2011, to help overcome any lingering negative feelings about prior management initiatives and deepen employee engagement, the CI department launched a friendly, site-wide competition. Based on twice monthly 5S audits, the teams in eight areas across the DC competed for the highest scores. The shipping department, which can be one of the most cluttered and hectic areas in any warehouse, won the competition the first year. Rewards included electronic devices and paid time off.

When developing its lean training materials, LifeWay uses stories from scripture. “It really drives the points home with our employees,” says Nicole Hudson, manager of continuous improvement.

To connect with people and inject a little levity, the annual competitions have used auto racing and Olympics themes. One year the LifeWay CI team used a “river of waste” metaphor, portraying problems as rocks in the water. Since then the site’s shared language around problem-solving has become all about “crushing rocks.”

The respect for people mindset at LifeWay has been reinforced by the management training programs offered by Aubrey Daniels International. These programs are based on concepts presented in the company founder’s book, Bringing Out the Best in People. Every member of the LifeWay leadership team has been through the behavior-based management and coaching program. It offers a model for analyzing individual performance issues and teaches managers how to deliver positive and constructive feedback.

For example, if someone is having difficulty following a prescribed process, managers will look at their behavior. Do they know a better way, or is the issue that they don’t want to do it in the prescribed way. If they don’t want to do it that way, why not? By breaking down outcomes into behaviors, managers can reinforce the desirable behaviors, and address the undesirable ones.

Interestingly, one of the tactics that Aubrey Daniels discourages is competition. That’s a difficult inclination to underplay among a competitive group of people like the folks at LifeWay. Nevertheless, they have modified the annual site-wide competitions to make them more collaborative.

This spring and summer the competition’s theme is the Old Testament story of Joshua and the Israelites bringing down the walls around Jericho. As people crush rocks, a figurative 12-foot wall will slowly be torn down. Appropriately enough, when a rock is crushed and the savings are documented and verified, a manager blows a ram’s horn. To date the cumulative annual savings from these efforts exceeds $1.5 million.

“Since 2010 we’ve tried to come up with creative ideas to involve our employees in continually looking for and solving problems,” says Hudson. “We want to create a culture where employees feel safe and know they can bring issues to their supervisors, and that they will be heard.”

Keeping the Faith

A high-performing work culture is something that people can begin to take for granted. Such acclimatization is normal, but LifeWay’s distribution center is far from the norm. Employees who have left to go to similar operations that opened up in the vicinity have often come back with a much clearer understanding of what makes this operation so unique and special.

When asked if they have any lessons for other companies on a similar journey, LifeWay’s CI team goes back to its early lesson about involving people in making any improvements to work areas. You will never get much traction simply telling people what to do, advises Hudson.

“It’s not for nothing for our group to go down and help throw boxes and move carts whenever we need to,” she states. “If you go and talk to people, if they see you on the floor helping, then when you involve them in the decision-making of their job, that’s when you get their buy-in. You have to include them from the very beginning.”

Lean Problem Solving, With Nehemiah

When developing its lean training materials, the LifeWay DC in Lebanon, Tenn., uses stories from scripture. “It really drives the points home with our employees,” says Nicole Hudson, manager of continuous improvement. “It helps show them that God’s teachings still apply today just like they did back then, if not even more.”

Here’s an edited example showing how the problem-solving training developed by LifeWay’s continuous improvement department draws on the book of Nehemiah for inspiration.

| Step 1: Identify the Problem | The first step in the Bible teaching about resolving issues is to identify the problem. Nehemiah inquired into the condition of Jerusalem and the Jews there. He discovered that, “The remnant there in the province who survived the captivity are in great distress and reproach, and the wall of Jerusalem is broken down and its gates are burned with fire” (Jeremiah 1:2, 3). When you and I approach a situation, we can ask questions such as, “What is wrong? What are the symptoms/conditions? What should the situation be like? Who is affected? We should get as many facts as possible, then weigh them carefully. The clearer we define the problem, the better our solution. |

| Step 2: Prayer is Needed | Nehemiah wrote that he, “sat down and wept and mourned for days; and I was fasting and praying before the God of heaven” (Nehemiah 1:4). Surely, in faith we must approach God for wisdom, direction, and strength (cf. James 1:5-6). In our humility, we need to capture God’s perspective. |

| Step 3: Identify the Causes | The Bible teaching about making good decisions reveals that Nehemiah identified several causes of Jerusalem’s plight. They were spiritual (1:6-9), discouraged, leaderless people, lack of resources, and local opposition (1:3; 2:7-10). You and I can seek answers to questions like, What are the causes of the problem? When did the problem happen? Where did it happen? How did it occur? Who was involved? What result came from what activity? Continually ask who, what, where, why, when, and how questions. |

| Step 4: Identify Several Possible Solutions | In the Bible Nehemiah had several options. He could have done nothing, appointed a group to go try to get the local Jews moving, or make a deal with Sanballat and Tobiah, the local leaders who opposed the Jews. However, he carefully considered before God what to do. In the first steps of problem solving, brainstorming is critical. You must keep your mind open to any and all the information and ideas you can gather. Consider all the interest groups involved and their legitimate interests. Think of ways to make it a win-win situation for all the players, be creative, and come up with as many solutions as you can. |

| Step 5: Pick the Best Solution | Sooner or later, you must choose what you think is the best solution. First, evaluate each proposed solution. Consider the advantages and disadvantages of each position. Combine the best features of several solutions to come up with new approaches. As you evaluate each solution, ask, “If I choose this solution, what is it I am going to get that I don’t want, and can I live with it?” Nehemiah chose to approach the king and secure the resources and permission to fix the problem in Jerusalem (Nehemiah 2:4, 5). He took action and made a decision. |

| Step 6: Devise and Implement a Plan | In this step you must determine a definite goal and identify the specific steps to reach the goal. Answer the questions such as, “What are the actions to take? How and where will the action take place? Who will be involved? How can the chosen solution best be translated into action? How can I get the resources? What is the time schedule?” \ From Nehemiah 2:6 and onward, you can study the story of how Nehemiah carefully put together a plan, overcame challenges, made modifications, and achieved his goal. We must plan our work, and work our plan, just like he did. |

| Step 7: Evaluate | How will we ever know if the problem is solved if we do not investigate? Regular, periodic inspections or checkpoints need to be placed into your problem-solving plan. There needs to be a final evaluation to determine what worked, and what can be improved the next time around. We can detect Nehemiah’s careful eye to detail in his problem solving and evaluation, “So the wall was completed on the twenty-fifth of the month Elul, in fifty-two days” (Nehemiah 6:15). |

Source of Nehemiah bible teaching: Newman International.

Learn More About:

How to improve efficiency 15% to 30% while reducing injuries and damage with gemba-based, on-site training for implementing lean in warehouse and distribution operations.

Virtual Lean Learning Experience (VLX)

A continuing education service offering the latest in lean leadership and management.