Dear Gemba Coach,

I understand now there is “real lean” and “fake lean.” I suspect my company has been practicing fake lean all these years. If I wanted to learn real lean, where should I start?

“Sell one, make one.” It’s hard to answer in generic terms because it really depends on where you are in the organization, but whatever your job the breakthrough moment is to understand takt time.

First, we need a “true north,” an ideal that is based on what we should do, not what we currently can do. This true north is “sell one, make one,” and then “use one, procure one.” It’s an ideal because it forces you to:

- Stay tuned with real customer demand: If you only offer what has just been sold, you’re pretty sure that you will focus on what sells, and not build up inventory of what doesn’t sell (and then must discount it to move it).

- Get it right the first time: If you only have one job in stock when customers ask for it, then it’d better be right, which means you don’t have space for rework or replacing a defective product with a good one from the shelf: each product must be defect free.

- Right-size investment: If you invest in flexible equipment, you’ll be able to follow what customers actually want.

- Develop supplier partnership: If you build solid relationships with good suppliers, you can execute “use one, procure one.”

- Innovate to attract: If you keep offering customers new features in the spirit of the time, they’ll become lifelong customers.

Et voilà, you’re doing real lean. Obviously, this ideal is untenable in practice. Nothing in life is set up to work that way.

Real lean starts when you, as a manager, stop issuing instructions and instead start working on problems with your team.First, you’d like an order book of future jobs to make sure you can work continuously and not just sit idly hoping that customers will come along. In effect, you want an “inventory” of future customers to feel safe. That is an interesting question all in itself. Whatever service your department sells, externally or in the organization, how do you ensure you’re always relevant and in demand?

Secondly, it’s hard to organize delivery if we wait for customers to show up and ask for stuff. Think of a restaurant, where nothing much happens until lunch, and then customers rush in at once and start queuing. This is where takt time helps. Rather than think in terms of “I’ve got to serve so many dishes a day,” turn the question around and think “I’ve got to serve a dish every two minutes during the lunch break.”

Looking with “Takt Time Eyes”

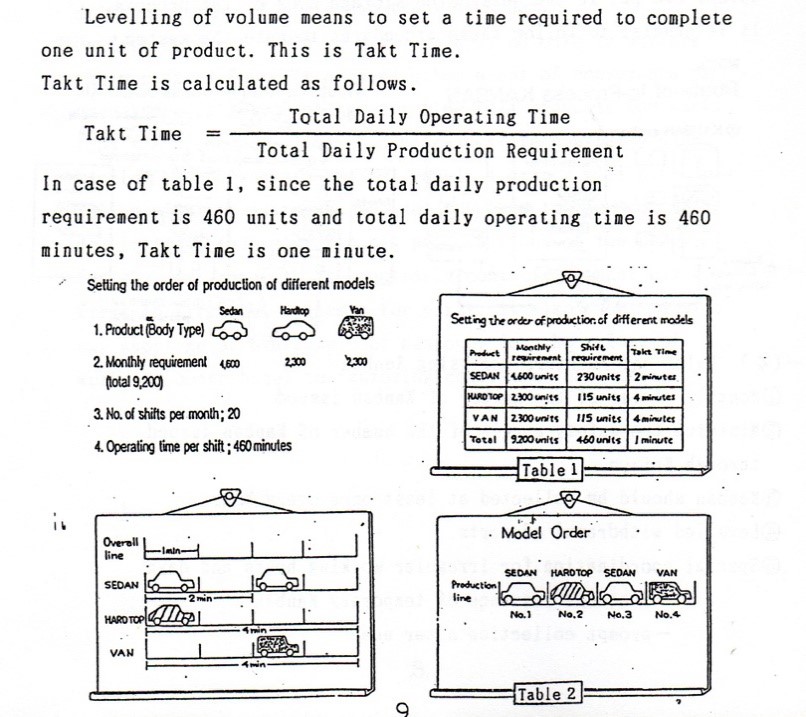

Takt time is “open time/averaged customer demand.” You know how long lunch takes, say from an 11:00 am slow start to a 3:00 PM slow finish, and you know roughly how many customers you get each day. Therefore, you can calculate serving a customer every two minutes.

This means that you can prepare: how do we set up the restaurant so that we can actually handle one every two minutes? This is where building smart stock is important. How can we make today’s special both 1/ prepared in advance and 2/ so attractive and interesting that people will actually order it? This is also where right-sizing equipment is important: how do we have enough grills to handle one steak every six minutes if one out of three customers takes steak. And a flexible grill that can take one steak, one fish, one steak, one fish.

Looking with takt time eyes will completely change how you see your business. Why are people queueing up? Oh, look, this table has finished but no one is bringing them the check or clearing up after them.

Now I hear you object: but that would mean I would need more help in the restaurant – it would ruin me! Think of the staff costs.

What that really means is that you start thinking lean:

- Customer productivity: How much money do customers happily leave on the table? (they thank you and smile as they pay the bill – and will recommend your restaurant)

- Asset productivity: How smoothly do customers flow in and out of your restaurant so that it’s in full use? How do you encourage them to come earlier? What can you do about slow times?

- Labor productivity: How do you make sure that each staff member’s work is easy, smooth, and seamless so that they can work effectively while feeling good about doing their job and transferring this good mood to your customers?

- Material productivity: How do you buy the best quality at the best price and supply just-in-time with reliable partners?

Now you will see that starting with “sell one, make one,” points to your biggest source of waste in flow interruption. As you observe how things go with lean glasses, you will discover that flow is interrupted all the time by:

- Friction: Something unpredictable that throws everyone out of synch and that people are not prepared to deal with. Work hard at making the unpredictable predictable.

- Ignorance: Someone doesn’t know something and does something silly, creating chaos. Learning must happen every day to deepen everyone’s understanding of what they do.

- Management: Some bloody stupid decision you took that pissed off everyone and now the day is ruined – and it’ll cost you money both today and tomorrow.

- Moods: Human, both customers and staff have moods, and the first skill of management is to console people who come in with their troubles to put them back in a good frame of mind, either to dine or to work.

Once you’ve calculated a takt time – both overall and by-product – you’ll see the endless flow of problems that stop you from achieving takt time every time. This is good news.

Source: Toyota

Aligning Smiles

Real lean starts when you, as a manager, stop issuing instructions and instead start working on problems with your team. There are occurrence problems (how do we deal with this unexpected situation right now?) and kaizen problems (how can we improve this issue we keep stumbling upon every day?).

And now you find yourself practicing real lean:

- What is the takt time to stay close to “sell one, make one” and not interrupt the flow of business?

- Why can’t we better train ourselves as a team to handle occurrence problems as they occur, make the unpredictable predictable, and react with a smile and a countermeasure when someone hits a snag?

- How can we enrich our working environment by pacifying it every day with good housekeeping and then improve one thing after the other in order to deepen our understanding and enjoyment of what we do – and keep being attractive to our customers as well as make a profit?

Certainly, fully grasping the details of the lean tools is important. Yes, absolutely, working with a sensei is the best way to deepen one’s appreciation of the lean principles.

But when all is said and done, real lean is a question of motivation, genuinely seeking to align customer smiles and employee smiles, and intention, supporting insights and initiatives to make all small things work all the time to discover what is heritage (what makes customers like us), legacy (what holds us back) and where to innovate to both keep our brand strength and be in tune with current tastes.