Dear Gemba Coach,

My company is trying to implement a system for collecting, organizing, and maintaining visibility of employee suggestions and ideas. I think we all know that the “suggestion box” has gone by the wayside. How do we solicit feedback from the shop floor without being overwhelmed by the enormous amount of amazing ideas that we’re asking for?

Twenty years ago or so, I visited the best lean plant I knew outside of Toyota, in northern Spain. The plant manager told me he only looked at one number daily: the number of suggestions made the day before. As we walked through the plant, he explained that he envisioned his job as observing how each cell was performing, pointing out problems to team members, team leaders and supervisors and encouraging suggestions from team members. This plant tour impressed me deeply to this day in demonstrating how macro-results, one of the best performing plants in its category, could be linked to such micro-improvements.

Suggestions are indeed one of the least familiar tools of the lean toolbox because of, I believe, the same difficulty everyone has with lean: it starts with the individual employee. Value stream mapping is easy to grasp. It’s a high-level tool not so different from reengineering where the manager can visualize redesigning the entire process. Suggestions, on the other hand, require involvement at the most detailed level, with the operators themselves.

What’s the Problem

Suggestions, nonetheless, are central to lean’s search for perfection. We often mention Taiichi Ohno as the originator of lean, occasionally stressing the impact of Kiichiro Toyoda as the theorist of just-in-time and his father Sakichi Toyoda as the inventor of jidoka. Yet, the less familiar figure is Eiji Toyoda, the legendary boss of the Toyota Motor Company who over his long tenure turned a bankrupt local company into the powerhouse it became.

Not often in the limelight (he once griped that Ohno was better known than he was), Eiji Toyoda protected Ohno from all the internal naysayers, supported the development of TPS and encouraged its spread to suppliers. More focused on the engineering side of the business, Eiji nevertheless has a determining influence on the budding TPS – he came back from a month-long training visit in Ford plants with a model for a suggestion system. His vision of suggestions as a way to involve employees influenced very strongly how the TPS evolved, and what “real” lean is about.

To return to your question, before we discuss tools, let’s ask again the fundamental question: what is the problem you’re trying to solve? Are you trying to:

- Administer the suggestions from the shop floor so you can evaluate them, pick the best ones, and implement them (and eventually reward them)?

- Encourage employee engagement and involvement in improving their own work environment?

These are two very different projects. In interviews, Eiji Toyoda describes how the Ford suggestion system was geared towards finding the best ideas to improve profitability. His own idea was very different: how to engage every mind to come up with better ways of working and give people more responsibility and ownership over their work areas. His vision was summarized then by the slogan: “Good thinking, Good products” (A slogan picked up from an in-house contest in 1953 after the creation of the Creative Ideas and Suggestion System).

If we seek to improve engagement and involvement we need to look at these two dimensions:

- Engagement: enthusiasm and absorption in the work that translates into extra-inch effort to further the company’s aims. Engagement is mostly about grappling with problems and showing initiative and creativity to overcome them.

- Involvement: feeling part of the team, and the company beyond and showing it through active participation in activities beyond the minimal definition of their role.

Key to Engaging and Involving

Engagement is therefore necessary to spot a problem, take personal responsibility for it (feel that it’s up to you to do something about it and not simply live with it) and come up with a suggestion. Involvement is about enriching the relationships with the team leader and the supervisor in order to move from suggestion to full resolution and also to convince other members of the team that the suggestion is a good one. In this sense, the suggestion process is the following:

- Spot an obstacle to doing good work and think about it

- Come up with a suggestion to improve the work environment

- Test it to see if it will actually do the job and adopt or adjust

- Convince other members of the team that it’s a better way of working

- Get it implemented in the company’s standards.

As we can see this is a tall order for an employee to do it on their own. The key then to engaging and involving suggestions is training frontline management to support the suggestion process.

Tools, then. Back in the Spanish plant, the plant manager had set up a system copying what Toyota was doing at the time:

- The team leader helped the operator write a suggestion form with before/after and expected gain

- This form went on a board (responsibility of the area supervisor) that showed the progress from New, to Accepted with the week, to Requiring more than one week to be evaluated, to Realized.

- The plant manager check the boards on the shop floor to see that suggestions were looked speedily enough and check how they were handled by supervisors.

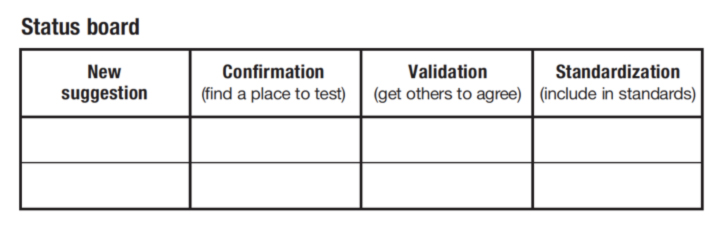

In Lead With Respect, we use a slightly different board for smaller companies, one less reliant on forms and bureaucracy:

Whatever tools you use (Toyota used suggestion boxes when it first started with its Creative Ideas and Suggestion System), the key to success is discussing with the management team the purpose of your efforts:

- What are your improvement goals in establishing a suggestion system: what problem are you trying to solve and what do you want to see improving?

- What tool will you choose and what process will you put in place to support the tool: for instance, how will you reward suggestions? Will you pick a “suggestion of the month?”

- How will you train frontline managers and team leaders to understand the purpose of the system, its operations and how to support their own team members in making suggestions?

Without these fundamentals in place the suggestion system, whatever form you chose, will devolve into a bureaucratic exercise, same a so many other attempts at suggestions in numerous companies. The issue is not the tool itself, but the kaizen intent behind the tool.