In this video, my friend and former colleague Susan DeSandre mentions the “matched pair” initiative at Ford Motor Company. I thought it might be helpful to explain this concept in a bit more detail.

Building an Aligned Team

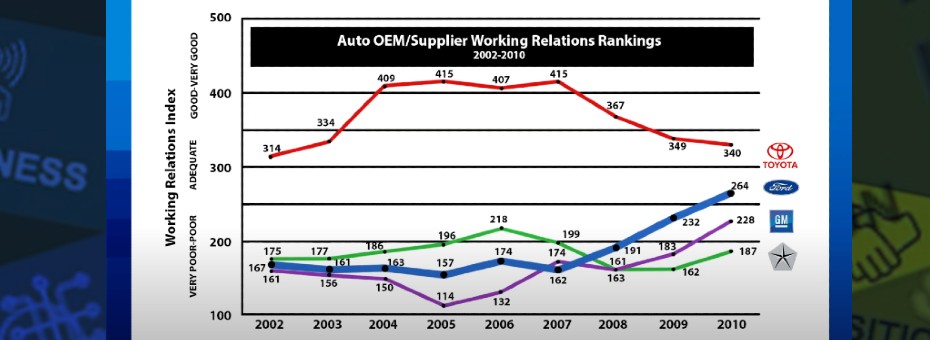

Conflicting objectives and the resulting organizational feuding had caused poor relationships to develop between Supply Chain and Engineering at Ford. This internal strife then contributed to poor supplier relationships, which ultimately proved quite costly for the company in terms of cost, quality, and technology.

As a countermeasure, the Supply Chain and Engineering leadership established the “matched pairs” initiative to improve transparency, teamwork, and communication both within Ford and with its supplier partners. They started the matched pair structure with the global directors of supply chain and engineering for each major vehicle system such as Electrical, Powertrain, Chassis, and Body. They then cascaded the structure down within each organization to subsystem chiefs, managers, and supervisors, establishing aligned and jointly owned targets for all supplier–related activities at each level. This structure was applied across all the new–model programs, annual cost reduction objectives, and long-term vehicle subsystem strategies, as jointly established by Commodity Business Plans. To enable the teams to work together effectively, they created an operating system, shared metrics, and basic infrastructure that was all orchestrated during the Monday morning meetings mentioned in the video.

Better Teamwork = Better Results

The matched pair work resulted in much stronger relationships both inside and outside Ford. Additionally, the resulting improved teamwork led to significantly lower costs, shorter lead times, improved quality, and better technologies that Ford could share with its customers. What’s more, matched pairing created a dramatically improved working environment for all of us.

Going Beyond Ford

Susan later went on to do similar work — in spirit if not in structure — at Apple. Also, at least one of LEI’s LPPD Learning Partners is experimenting with “matched trios” by adding manufacturing engineers to the mix. The point is that no matter the specific countermeasure applied, improved teamwork results in better performance no matter the industry.

Designing the Future

An Introduction to Lean Product and Process Development.