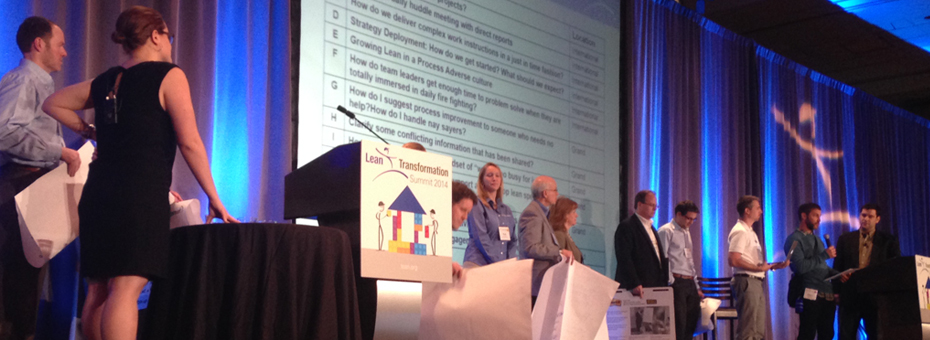

At last week’s Open Space session in Orlando, Summit attendees hosted 12 different conversations on their challenges related lean thinking practice. At the end, each group reported back their learning to the larger group and shared their notes with us at LEI.

These conversations are one way we at LEI learn more about our customer and community. But more importantly, they’re a way for you, lean practitioners, to learn from each other and strengthen your own capabilities for Lean. Check out the ideas that emerged from last week Open Space and let us know what you think. Contribute your own ideas/suggestions in the comments below and let’s keep these conversations going!

1. How do team leaders get enough time to problem solve when they are totally immersed in the daily work of firefighting?

Develop a coaching plan. Use good examples and small wins by focusing efforts in successful projects and remove “crutches” of the old process to turn fire fighters into coaches. Small wins are important. Use examples to show how flow is better than batching. Look for opportunities to streamline processes. Involve team in determining and implementing improvements. Provide good examples to team of successful environments. Focus efforts on a project to use as an example and prove ground for Lean. Remove crutches for the old way of doing business. Focus on organizational awareness, and develop lean primer. Convert fire fighters to coaches.

2. Growing lean leaders in a process averse culture.

Focus on the individual and/or organizational need and problem. Connect with what is important to them! Select appropriate approach to address need and/or problem (and don’t push/sell process). Realize success and then move to next need and/or problem. Get a lean thought partner and ask for an assist. Use a marketing approach, sell the heck out of it. Raise the bar with benchmarking. Meet the team where THEY are. Ask and help answer the question, WIIFM (what’s in it for me?). Go and see successful areas. Breakthrough goals (based on a “true north”) require more than business as usual. Use a grassroots approach in which associates push leadership to action. Constancy of messaging keeps the pressure on.

3. Applying Lean into knowledge work… What metrics help make the work visible and indicate productivity?

Value stream mapping, customer/supplier, connections/deliverables. Problem solving engagement with teams.

With dispersed teams: Make sure you have executive commitment, make sure there’s a support system in the field, create a roadmap for how leadership needs to change, leverage social media, use tiered pulse checks, create a common language.

4. How do we get senior level engagement in Lean when it doesn’t exist?

Have to prove it with a pilot. Tie to sustainability and more overall results. Create pull. Create a leader playbook. Discuss succession planning: who needs to be developed? Use a holistic approach. Use plain English. Answer the question, what makes Lean different than every other solution? Identify waste in the organization. Put together a package that the C-suite can understand. Create opportunities for CEOs talk to each other.

5. Strategy deployment… How do we get started? What should we expect?

(25 attempts represented in this group and 3 would call themselves “successful”.)

It’s critical to first create stability before tackling breakthroughs. You’ll feel like the lone wolf. Ask what does “engaged” mean? What has been tried already? Be a salesman or get one. ID the right person. Focus on business measures. Consider Lean boot camps. Get a champion. Find a specific problem that an executive is concerned about and solve it. A tools conversation won’t work. Find the right message for the right person, be strategic. Treat Lean as a lean event (use an A3). Put ownership of fact finding and solution on the individual. Sell the program by demonstrating how others have succeeded. Improve the process, the results will follow. You’ll need an experience base of 1-10 yrs. Important to develop internal coaches.

Open questions: With regard to executive understanding, what do you do when you hit the ceiling of understanding? How do you make a revenue center when you have never been one before? What is the right composition for the improvement team?

6. How can corporations better support and develop lean specialists that drive change within their organizations?

Identify talent. Hire a sensei. Executive endorsement and training. Highlight early successes. Celebrate milestones. Create clear alignment around purpose. Use Lean as a rotational program and career development tool. Establish meaningful metrics. Experimentation – accept failure. Clear roles and empowerment responsibilities. Lean as part of corporate strategy led by CEOs/pres. Interaction within leadership at the gemba (process in place). Indoctrination of new people. Lean not a cost reduction tool (be clear about this, no layoffs). Lean tune up w/external partnerships.

7. How do we deliver complex work instructions in a just-in-time fashion?

Build a problem solving focused coaching curriculum. Make sure to teach basic skills taught at all levels (PDCA, change management, willingness to identify problem). Coaching for management. Coaching cycles based on Mike Rother’s work. Build expectations into the annual review process. Tie work instructions into meetings. For those who have completed training, ask them to coach others.

8. How to overcome leaders’ mindsets of “we’re too busy for Lean”?

Communicate the need to see financial resulsts. Ask, is there an executive who is a lean champion? Ask, what is the business case for change? Challenge the team to find time. Demonstrate quick wins. Remember, Lean is not something “done to” the organization, it’s part of the work. Create a burning platform for Lean. Benchmark other organizations and teams. Set the right metrics. Go and see. Look at recurring problems. Build community and involve everyone in kaizen events. Demonstrate the right problem solving process. Focus on communication of what Lean is about. Create science fair gallery/walk through to share projects. Incorporate the voice of the customer into monthly meetings. Remind people, you free up time for Lean through Lean.

9. How to manage multiple projects.

Create project plans that link to the greater project. Create a line of sight to the larger goal. Determine ownership for each project and link projects to hoshin. Ask, what are your key success factors? What gets in the way? How do visual boards help and not help? How do you create a plan where you give as little [direction] as possible/as much as necessary? With strategy, thinks gaps AND overlaps.

10. Running a daily huddle meeting with direct reports.

Manufacturing: Do a an every day huddle, focus on andons and problem solving. Stand up in front of board, do a round robin on quality, safety, and maintenance. Don’t actually problem solve in the huddle, but bring the problem to the huddle and get clear on ownership. There shouldn’t be criticism for posting a problem on the board. No reprimands for bringing problems forth.

Service: Meet at various locations with the organization. Record accountability. Meet in various locations, stand up by value stream with visuals and mark “by when” date. Rotate facilitators. Trickle down activities within departments, trickle up activities as upper management attends meetings. Do a virtual huddle weekly with managers. For each huddle, come with a problem solution from the previous day’s huddle. Must do this every day with every shift. Daily, weekly, monthly, yearly. Give updates within 5 minutes (meetings take less time the longer you do them). It’s like a football huddle, “plan your plays and run your plan”.

Top take aways: Huddles should be no longer than 15 min. Respect everyone’s time. Don’t problem solve in huddle, but clear on responsibilities. Who, what, where, when. Use a consistent, structured template for the meeting. Use visuals. As for scope, look 24 hours ahead and 24 hours back.

11. Let’s clarify some conflicting information about Lean that has been shared here at the Summit.

On standard work: How standard is a standard? You can’t copy standards. We must understand lean thinking and apply to our own situation. PDCA is the standard.

Set based doesn’t equal try/fail, try/fail. It equals drive multiple options, delay decision, options, down select, rapid learning cycles.

What’s the level of ground crew involvement? It depends.

Using a parking lot works well for scoping/meetings/etc.

With kata, pick one area of focus and go.

12. How do we suggest process improvement to someone who needs no help? How do we handle naysayers?

Pilot to prove results. Agree on a problem. Ask, what is the cost of doing nothing? Ask what’s bugging people. Challenge the line/idea: “This is how we’ve always done it.” Get a sponsor on board. Attack process, not people and focus on relieving burden. Use peer testimonials. Name what’s in it for the customer and for the employee/team member. Do gemba walks to go and see processes. Remember, for some people, losing the role of “the expert” is scary. Start by agreeing with this person on what’s really going on. Ask, do you work in a utopia? Ask, how was your work day?

Consider “key concepts of lean” training. Start with value stream mapping. Use A3s across the organization. Look for waves of transformation, and show successes to gain traction.