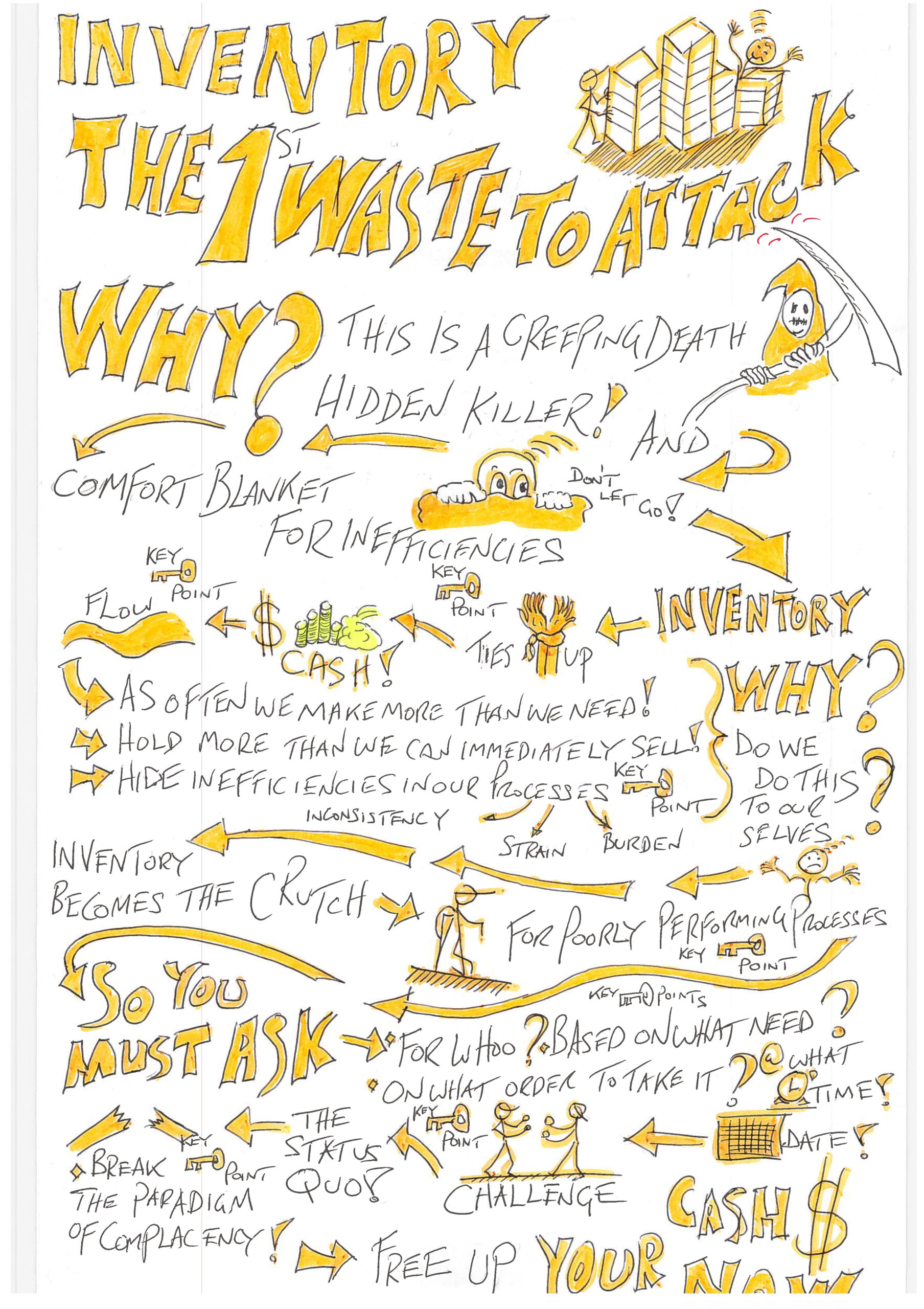

In my last post I talked about what I see as the four areas in manufacturing where waste can be found: Conveyance, Inventory, Process, and Inspection. When I tell people about this, their first question is almost always the same: “So where do we start?” I say Inventory, and here’s why.

The one-word answer is money. Cash flow in any business is critical so it’s important not to tie it up! If you’re not doing everything right, Inventory has a tendency to quickly absorb cash flow – and it goes without saying that that’s never a good thing. Even worse, it can hide inefficiencies in the other three areas of waste within manufacturing. See my sketch for more details on waste in Inventory and see if there’s an opportunity to eliminate Inventory waste.

Once you’ve reviewed the sketch, I encourage you to check out this animated video I made to go along with it. It’s something I hope you can share with others to educate and convince them where your gemba walks and kaizen events should be focused first.