Dear Gemba Coach,

I understand that kanban is an important part of lean, but I work in an office environment and it’s hard to see how production orders on cardboard cards relate to improving project management – what am I missing?

As my co-author of The Lean Strategy Orry Fiume says: time is the unit of lean.

“The thing about time,” he explains, “is that it is the only resource that you can’t buy more of. You can buy more machines, hire more people, but time is finite … 24 hours in a day with no possibility of increasing that. The only way we can “get” more time is to eliminate nonvalue-adding activities that consume some of our 24 hours. This accomplishes two things. It compresses the lead time for satisfying customer demand and frees up time (capacity) for more value-adding activities needed for increasing demand (growth).”

Before the Toyota Production System became codified in Toyota in the 1970s, it was known as the “Ohno system,” then the “kanban system,” and kanbans are indeed central to the whole concept of lean. Principles such as jidoka (adding human intelligence to automation) or just-in-time have a long history in the company, but it only came together when, as legend has it, Taiichi Ohno had an original insight looking at photos of American supermarkets in the 1950s and figured out he needed takt time for assembly and a fixed batch replenishment system for components.

The cards are only one device. Anything can work as a kanban – and indeed, anything does. I’ve seen colored nuts (as in nuts and bolts), triangles, paper, containers, and so on. The “kanban” is really a signal, an order – a physical thing that visualizes the just-in-time principle of “sell one, make one.” The four key things to look into are:

- What is the point of kanban?

- What does it reveal?

- What does it allow you to do?

- What’s the big deal?

Office Opaqueness

Taiichi Ohno came up with the idea of kanban cards when he was thinking through an apparently impossible problem. Back in 1949, Toyota was almost bankrupt and its executives had somehow computed that American automakers were at least eight times as efficient as Japanese ones. Ohno, however, could not believe that American workers were exerting eight times more energy as the Japanese. He, therefore, concluded that the Japanese were probably very wasteful in the way they worked.

What he essentially saw was that a lot of resources were casually used to do stuff that wasn’t serving customers’ needs NOW! This is the experience you’ll have in any store when the people are busy sorting boxes or looking in the computer and there is no one available to take care of you. They are working. What they do is probably useful and necessary to run the shop – no debate. But right now, nothing matters more than keeping one more customer happy. Lose one customer, lose 250. And sorting boxes won’t put any money in the till.

This is easy to see in a shop situation, but in the office, it becomes very opaque. Ask yourself: “How do I know that the e-mails I’ve answered this morning or the meetings I’ve been to are of any immediate use to a customer” (be it an internal one). Am I answering direct requests, or doing things that need doing because, well … they need doing.

Deliver This Now!

The idea of just-in-time is that the subsequent process must come to you to ask for work, withdraw what it needs when it needs it and in the quantity it needs, and you should be exclusively focused on delivering that rather than doing everything else.

Which doesn’t mean that everything else doesn’t scream to get done as well. The point is that if you start your day with a to-do list, you decide what is a priority to get your job done – not your customers. I’m writing this column today because my editor has asked me to. I don’t particularly feel like it and believe me, I have, many, many other things to do. But that’s kanban for you – it establishes the real priority of “pull.” In fact, by writing this column now, I can’t go wrong. My editor has asked for it, it goes to my readers – of course, this is a timely and effective use of my time.

Essentially, kanban is a visual tool to visualize real, clear, and present demand from the next step in the process towards the customer. Rather than a long list of things to do in which you can choose the one you tackle first, it comes as a queue of singular instructions saying “deliver this now!” It visualizes work as if there were a queue of people waiting at your desk.

“Now!” will immediately reveal that, when tackling a to-do list, we tend to choose the easy items to do first in order to get ahead, which is perfectly normal. This morning, for instance, I have an endless pile of e-mails to answer and admin to sort out which will need to be done and are way easier than writing about kanban. As a result, we do the easy stuff, then the day starts and we get distracted by whatever happens, and by the end of the day when we’re finally ready to do the hard stuff, we’ve got no energy left so we tell ourselves “I’ll do this first thing in the morning” as it is still on the to-do list and so on. Kanban forces you to do what needs doing when it needs doing.

In production, for instance, the hard thing to do is change tools to switch from one batch of As to a batch of Bs, so it’s easy to be tempted to run the longer batches to avoid the hassle of changing production. Then some changes are easier to do than others, so we tend to schedule these first and so on. As a result, you’re busy doing As, you’ve planned to do Bs, but are running really low in the inventory of Cs – and will never notice. The kanban cards visualize what needs to be done next and changing the tooling easily, smoothly, and fast is your main problem. Not rescheduling production.

Kanban, in whatever form, visualizes the gap between customers instant demand and when the specific product they’ve asked for will be produced (a gap often hidden by an inventory of stuff when they’re standardized products, or hidden in a backlog). Kanban is not a production instruction; it’s a visualization of your response time to any request, and it shows whether you’re working on it right away or prioritizing something else instead.

Kanban reveals the gap between what needs to be done now, and what we’re really working on in a way that everyone can see and discuss.

Surfacing Problems

And? What does this enable us to do? As Fujio Cho, a legendary Toyota president, explains, “TPS was able to significantly reduce lead-time and cost, while constantly improving quality. This made Toyota one of the ten largest companies in the world, It is currently as profitable as all the other car companies of the world put together.” The game plan is pretty clear: reduce lead-time, reduce costs, improve quality — but how does that work?

Well, to start with, a kanban is considered delivered only if the parts or job is considered good by the following process. If not, the job is refused and it needs to be redone right now – so all the kanbans in the queue simply stall, which shows, and creates a panic, and hopefully a reaction to solve the quality problems right away.

Beyond big crises like this, kanbans actually measure the time between the request and the response. In many activities, this time is more or less standard. For instance, when my editor asks me for a Gemba Coach column, he knows I tend to respond within the week. When I don’t he asks me what’s wrong because, basically, he knows something is – there is a problem we need to solve.

Kanbans allow you to identify real problems right away. Whenever the kanban cards don’t flow as they should, you’ve got a problem, and this is the starting point of developing people through problem-solving and learning to do better quality jobs and to better schedule our resources, which will invariably reduce costs as well.

As Toyota explained it back in the 1980s (Kanban, Just-in-time at Toyota, Productivity Press, 1985), “To provide timely information simply means that the manner of transmitting instructions must be consistent with the cycle time.

From the point of view of office work, it is much easier to give orders by the hour, or by the day, instead of by one and three-minute intervals. This is the reason why the information is given in a batch. But we must keep in mind that no matter how complex it may be for office workers, they should not be allowed to take an easy way out and contribute to the waste arising from overproduction.

Is office work that complex? The actual act of building a car and the act of ordering a car to be built cannot be compared. It is much easier to say something than to do it. Giving instructions is much easier than building a car.

To provide information by the minute also means that the company is engaged in abnormality control, showing how to act when something unusual happens. Toyota is not a company that would let the final product emerge without an overview or plan for it.

Entry Point to Lean

Secondly, kanbans also offer a massive opportunity for kaizen: you can tackle the “normal” lead-time and strive to reduce it. For instance, I could work on turning around Gemba Coach columns in a couple of days rather than a week. It doesn’t mean that I would write them in less time, just that I would respond faster to the kanban. This would lead me to question many aspects of my personal organization – and hit upon obvious difficulties. For instance, I write Gemba Coach at my desk. During the week, I travel to the gemba. I could learn to write on the train or plane. I have thought of this several times, but simply don’t know how to do it. Plain and simple I have a writing challenge that I don’t know how to solve but that would make me a far more effective writer. This is how Toyota got to be Toyota: tackling all the apparently impossible problems reducing lead-time revealed.

What’s the big deal? Kanban is the entry point to lean – you simply can’t think you’re practicing lean if you haven’t figured out some kind of kanban in your main activities. Kanban changes everything by changing your outlook: from stuff to time.

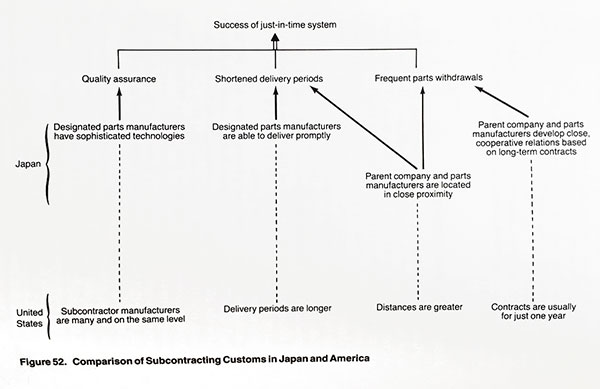

Kanban is the first step to changing your entire understanding of the production system, as shown by this graph representing, in the 1980s, the difference between subcontracting in Japan and in America:

This is the fundamental lesson that … most companies still haven’t learned. Anyone claiming to practice lean without kanban is simply kidding themselves.

I don’t know how to answer your specific question. I’d have to know a lot more about what work your office does. But kanban is not about the cards, it’s about measuring the lead-time between “sell one, make one.” You need to figure out some way of revealing the three gaps:

- Gap to single piece flow: Do you schedule item by item or do you batch work information?

- Gap to instant delivery: Do you make and deliver the job just as the customer asks for it?

- Gap to fully connected supply chain: How deeply do your kanbans go into the supply chain to create a full just-in-time system?

And then learn to solve the problems that crop up, one by one, both the abnormalities and the hard points of inflexibility. And to do this, you need to the involvement and engagement of everyone, everywhere, every day.