Dear Gemba Coach,

One of our outpatient wards reduced waiting time by 75% and got an award for their lean improvement project. But then momentum was lost and waiting time is now worse than it ever was. Is this loss of momentum normal?

Normal as in usual? Typical? Expected? Or unavoidable? Usual – let us say frequent. Typical – not really, it depends. Expected – sure, if you don’t do things right. Unavoidable, no. Much ink has flown in the lean literature about projects, momentum and top management support. In my experience, clearly, if top management is not leading the culture change by first personally learning how to think lean before asking others to do so, spot kaizen projects always disappear.

I remember a division VP in a plant in Germany very happy about the results of a kaizen workshop consultants had run for him in the plant. He was proudly showing me the powerpoint slides on his laptop, and I was puzzled because I had seen nothing on the gemba. Eventually, we walked down from the meeting room to the shop floor, finally found the cell in question and observed that everything (and I mean everything) from the workshop had disappeared and people had reverted to business as usual. Awkward.

In this case, the VP was definitely committed to lean thinking and in many cases leading the change himself – what happened?

We consistently misunderstand the role of middle management in lean changes. Typically, where Toyota talks about group leaders, team leaders and team members, we still talk about supervisors and operators – we walk past the leadership element.

Twenty years ago, I remember the senseis telling us time and time again that the first responsibility of the group leader was to maintain and develop visual control. Most of the plant visits my father did with his sensei were about visual control and the at-a-glance distinction between what is normal and what is abnormal. Lean thinking is essentially about seeking the ideal conditions for creating value without generating waste.

In a project situation, typically the project team analyses a current process, identifies flaws, brainstorms for solutions and implements fixes. And then walks away. While the focus remains on “checking” whether these solutions work, performance improves. Once the project has been validated and translated into “savings” and the circus has left town, people will quite normally revert to how they worked before. Why shouldn’t they? Noe of their issues have been resolved.

Visual control is a technique to translate the top management challenge in visual goals for every team member, so that they understand intuitively what they’re asked to do without having to be told. Yesterday on the gemba, the site manager of an aeronautics plants was telling me how excited he got when one of his line leaders had started measuring lead-time in her line. And then he had an “aha!” moment when he saw that the charts and numbers they were all so happy about would have no meaning for operators. Scratching their heads, they then came up with a way to visualize lead-time with open slots for products on a table, a kind of proto-kanban. Operators got it right away and the improvement wheel has started because both the middle manager and the operators are working on a problem in the daily course of their work without having to intellectualize it overmuch.

The gemba approach to lean changes runs opposite to the project one:

- Identify a performance improvement opportunity that makes sense at a business level: improve safety, improve product quality, reduce inventory, reduce unnecessary costs, etc.

- Figure out a way to visually control the issue with the team: lines on the floor, red bins, a production analysis board, a measles chart, Kanban, etc.

- Look out for the skills gap this visual control will highlight and train people: improvement is rarely hard because of will, but usually because of skill. Each new shop floor challenge typically reveals that employees are not so confident about this or that part of their work, and that’s okay – just a matter of one-to-one training.

- Improve the process: when people have been trained and when they follow the visual control, they’ll spontaneously have ideas on how to improve if their manager asks them and supports their initiatives.

- Find the next performance improvement opportunity: as the process improves, some doors close (thankfully) and new doors appear – which then need to be opened by going through the learning cycle again. The point is that as teams learn, so does management.

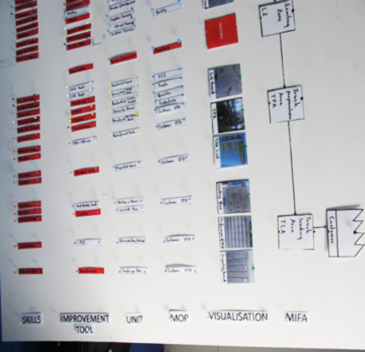

We were discussing this with my friends Paul Evans (plant manager) and Jiri Janatka (lean coach) in Czech Republic and they came up with this brilliant visual control for these same for steps (meta-visual control?):

For each step of the value stream, they check whether visual control is in place, whether there is a clear measure of performance is in place, whether they know an improve tool and whether they work at improving local skills – red tags are gaps. One board says it all!

Middle-management mastery of visual control techniques is the key to the sustainability of changes. It’s not mysterious, and not a culture or moral issue. Once you set up a roundabout at the entry of a village, motorists are far less likely to zoom through it. Signs along the road giving you feedback on your speed compared to the speed limit will lead to less speeding. Similarly, and visual control hack that leads to daily observations and discussions with the group leader about some aspect of the work will lead to sustainable improvement. At the end of the day, this is what gemba practice is: better observation and better discussion. When people understand, they usually act. To get them to understand, you need to have them try stuff first. Try visual control first.