Although lean principles and practices have broad application in manufacturing, the ease of that application can vary based on what is being produced, to whom it is being sold, competitive pressures, location, corporate structure, workforce characteristics, availability of raw materials, contractual obligations, and other attributes that make each lean journey different.

Buck Knives, a Post Falls, Idaho-based manufacturer of knives for outdoor recreation and personal use, had more reasons than most to eschew lean:

- Its three biggest customers are large chain retailers and catalogs, who can be highly demanding of suppliers and are notoriously inconsistent with replenishment and sales-forecast accuracy.

- Making high-quality knives involves craftsmanship skills, which don’t translate easily into standard work.

- Raw materials include both metals — which have long procurement cycles and volatile prices — and specialty materials such as giraffe bone and mother of pearl — which are rare, strictly regulated, and have complicated procurement requirements.

- Forty to forty-five percent of sales come in the last three months of the year, making for highly unleveled demand.

- As it started implementing lean, the company also had to relocate its company headquarters and manufacturing facility from San Diego to Post Falls and implement a new enterprise resource planning (ERP) system.

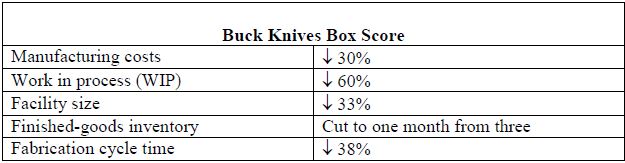

Despite these challenges, Buck Knives has so fervently embraced lean that it now does nearly everything differently — from allocations of costs for shop-floor supplies to working with its key retail customer to level load fulfillment. Buck’s efforts began with the creation of a single assembly cell while it was still a large-batch producer and occupied a plant that was 45% larger than its current plant. Since then, lean ideology has changed leadership’s thinking so much that they have thrown out their old performance metrics and are in the process of creating new ones that reflect the goals of lean.

Becoming Lean to Survive

Several factors led Buck leadership to determine in 2001 that the company had to drastically change if it wanted to keep manufacturing in the United States. The cost of doing business had risen dramatically in California, Buck’s home since the 1940s. Additionally, a sudden and unexpected sales drop of a key product and the recession that followed the 9-11 terrorist attacks led to three unprofitable years. Simultaneously, competitors in China were becoming better at manufacturing quality knives, and Buck managers calculated a 30% cost differential between their company and its overseas competitors.

“The business reason for launching lean was survival,” said CEO C.J. Buck, a descendent of company founders. “Tweaking was not going to keep up with the bleeding.”

The company created a five-year plan to reduce costs by at least 30% that included three key elements: moving to a state with lower energy, labor, and regulatory costs; buying a new ERP system; and creating a lean-oriented culture. The first two goals had long-term timeframes, but the company started on lean right away. They employed consultants, sent a group of 25 employees for off-site lean training, and began targeting production for improvement. At the time Buck operated with a mass-production model with disconnected functional areas. Finished-goods and WIP were everywhere.

“At any time, one of the production areas easily had two-to-three months of inventory,” said William Keys, director of lean manufacturing. “Five batches here, 10 batches there. And a batch ranged anywhere from 25 to 50 knives. We literally had thousands of knives in WIP inventory.”

Their first step was to convert from mass production to assembly cells. Keys said the first cell was created during the initial lean training and was successful. Leaders started with one group, and then that group trained another group and helped them to convert into a cell. This continued over several months until most of the production floor had been converted. By this time, the company began focusing more on its out-of-state move and devoted less time to expanding lean principles to other areas of the company. The cells continued to function successfully, and the company would occasionally hold teaching events. Although managers had much to do related to the relocation, lean thinking continued to influence their decisions.

“One of the things we realized when we were creating the assembly cells was that we had consolidated into an area that was about half the size, and we had reduced WIP by 60%.” Consequently, they decided that their next facility could be one-third smaller and should be designed to support flow. Also, once the company did relocate in 2005, it needed to hire about 200 new employees, all of whom it trained in lean concepts right away.

It was in September of 2005 that Buck CFO Phyllis Best took a group of Buck managers to a conference on lean accounting. Speakers included Brian Maskell, Orry Fiume, Jean Cunningham, and other people who were using new accounting concepts that better reflect and better support lean management than traditional accounting concepts. (Lean-accounting principles reward inventory reduction, favor value-creation over piece-part pricing, and give an accurate portrayal of cash flow and costs. Traditional accounting methods do not support these goals.)

“It was kind of a hard thing to accept,” Keys said. “It made sense, but some of the things were counter to what we had been doing since the company was founded. But they came back very much convinced that we had to move in this direction.”

The injection of these new accounting principles into Buck’s continuous improvement efforts — just when the company was reactivating its lean focus, launching production at a new site, and hiring new employees — acted as a catalyst to speed the permeation of lean throughout the culture. This happened because managers in the function that most drives strategic decision-making at the executive level — accounting and finance — became lean evangelists, just like the operations folks.

Converting to Value Streams

One of the first things companies often do when adopting lean accounting is to reorganize into value streams, which Buck did. Keys and others identified four value streams based on knife designs and added a fifth value stream to represent sourced knives, which the company manufacturers via contractors in China. They chose value-stream managers internally, picking the leaders based on experience. As with many companies that reorganize into value streams, Buck’s biggest hurdle came from operators who wanted to cling to functional roles, particularly in the area of blade fabrication, which includes a variety of skills with long histories of craftsmanship.

“Reorganizing into value streams is fairly easy,” Keys said. “The challenge is how to move forward after that. For instance, in Value Streams 1, 2, and 3, we began to include fabrication people. Their actual work didn’t change, but in Fabrication, people identified with Fabrication. They didn’t identify with a particular product. For instance, they would say, ‘We are hollow-grind operators.’ You have to realize that with the value streams, in a course of a day we changed how things had been done for 45 years.”

Keys said management’s strategy was to keep reinforcing what the goal was, how the company was going to achieve the goal, and why it was important to achieve the goal. “We still haven’t gotten to where we want to be, but it’s better than when we started,” Keys said.

Some batching still takes place in Fabrication, which has duties such as grinding and stamping knife blades, some of which are specialty knives made for collectors. Those batch sizes, however, are about half of their pre-value-stream sizes, and lead time in Fabrication has dropped from six to eight weeks to two to three weeks. Fabrication remains a target improvement area for the value streams, one of which has a goal of reducing fabrication time by 50% this year. Leading this kaizen are Bruce Sundahl, lean/continuous improvement manager, Jim Hypes, value-stream manager and Cindy Eby, a buyer for the value stream.

Additionally, Hypes and Jeff Hubbard, another value stream manager, are cross-training their employees in Assembly and Fabrication, seeding the effort with a group of production employees who became certified in lean through a local manufacturing-assistance program last summer and went through cross-training as part of the process.

Addressing Cyclical Sales

In addition to Fabrication, a small amount of batching still takes place in the heat-treating function and limited clam-shell packaging, but otherwise the entire production floor is organized into cells that are part of value streams. Each stream operates as a separate profit center and plans work according to a 30-day forecast that is produced at monthly meetings involving Sales, Accounting, and Operations. Prior to these cooperative meetings, Sales and Operations never communicated, and this fed excessive inventories of mismatched parts, overstocked finished goods, and piles of WIP waiting for the next process.

“When we started having joint meetings, we began to communicate in a new way,” CFO Best said. “And now, Sales is responsible for the sales forecast, and Operations is waiting to do their planning based on that forecast.”

Materials flow based on multiple kanban systems. Cells track performance on a white board, listing the production plan for each shift and metrics on how each cell is performing compared with the plan. The individual value streams manage their own costs.

To deal with the cyclical nature of the retail market, Buck decided to reduce finished-goods inventory to one month but increase flexibility with continuous improvement. It is also beginning to create vendor-managed inventory programs with some of its larger clients. Additionally, Buck began level-loading production for its largest client, Wal-Mart, which historically has been good at forecasting 12-month sales totals, but not so good at month-to-month forecasts. Buck takes Wal-Mart’s 12-month forecast and divides the totals into 10 equal amounts to beproduced each month between January and October. Now, instead of scrambling when Wal-Mart’s monthly forecasts change, Buck relies on this inventory or its increased flexibility to respond quickly if inventory can’t cover the monthly order.

“Sales has taken responsibility for the forecasting, and we are holding the plants [the Post Falls plant and contract plants in China] accountable for anything that they build over the planned, level load, so there’s a little bit of tension there,” Best said. “Sales might foresee a spike later in the year, and maybe Operations is just building to a kanban. So Sales might start to panic and say, ‘Maybe we should increase our forecast a little bit because we don’t see Operations responding.’ And manufacturing is standing back saying, ‘We’ve got plenty of time, we’ve got plenty of capacity. We don’t need to build that yet.’ We still build things we don’t need, but not nearly as much as we used to.”

As an example, the company historically has held two “clearance sales” each year to sell excess finished goods. In 2007, it didn’t have to hold any.

One way Buck increased flexibility was through a 5S effort that ultimately led to dispersing the packaging function (except for a small amount of clam-shell packaging) to individual cells within the value streams. The improvement began in 2007 when Sundahl launched a 5S initiative for packaging, which took place in one area outside of the cells. It was determined that more space was needed to address a bottleneck in packaging, and such an investment would cost “well above six figures,” according to Sundahl. Phil Duckett, executive vice president of Operations, challenged Bruce Sundahl to come up with an alternative. His response was to work collaboratively with the value-stream managers and shipping manger to move packaging to the cells. By early fall, they had proved the concept in one cell and in one value stream. Despite the looming busy season, Duckett gave Sundahl permission to continue with the change.

“Rather than putting their foot on the break, they put their foot on the gas pedal, and I think that helped with how fast the change happened,” Sundahl said. “Everyone knew that the busy season was coming, and we got it all converted in four months.”

The packaging move did more than allow Buck to avoid an expensive capital outlay, it also:

- Allowed for the reassignment of several employees to other areas because the cell-based tasks require fewer people.

- Removed a bottleneck in the supplier kanban system because the signals to suppliers would get hung up — sometimes for days — while finished goods waited for packaging.

- Helped the company to accept and complete all of its orders in the final quarter of 2007. Previously, the company would concentrate on filling high-volume orders and turn down smaller orders during this busy time. Because of the level-loading plan with Wal-Mart and because finished goods were packaged before orders came in, the company had enough capacity to complete all orders. It did not have to decline any sales opportunities.

Uncovering True Costs

Buck has increased flexibility in other ways and has reaped multiple benefits. Some of these opportunities, however, would have remained hidden had the company not converted to the lean-accounting practices taught by Maskell, whom it hired for training and consulting.

C.J. Buck gives this example:

The company uses a fine blank machine to cut blades from metal and was faced with having to invest in new customized tooling for the machine to produce a new product. Tooling would have cost as much as $80,000 and would have had a four-month turnaround. Maskell asked if the company had idle capacity elsewhere that could handle the increased demand. They did: a laser cutting machine, but it cuts blades at the rate of 60 to 80 an hour while the fine blank machine can produce 600 to 800 an hour.

According to traditional-accounting principles, the large-batch option would have been most profitable. But using lean-accounting principles, which favor flexibility over large-batch production, the laser machine was the better option, and that’s what the team chose.

“Looking at our capacity, we just don’t have that many products that need a rate of 800 an hour,” Buck said. “We actually had excess capacity in the fine blank machine. We needed help in the smaller runs. Standard costing says the obvious solution is to buy the machine that can make the most product, but that’s not what we needed.”

Best attributes the increased use of the laser-cutting machine and other changes with increasing flexibility enough to give the company a unique advantage. For instance, the company offers quick turnaround on customized consumer Web-based orders, something competitors can’t do. Additionally, the company expects to continue to save in tooling costs by using laser cutting.

“The laser is slower, but it allows you to have smaller batches and not invest in the tooling costs,” she said. “In the past the sales people would be optimistic about sales, which meant we would invest a lot in tooling sometimes, and then sales wouldn’t come through. Now we’ve smartened up. Now we say, ‘If demand gets there, we can always order the tooling.’ ”

Using the more holistic lean-accounting approach also led to the company pulling some work back from being outsourced to six Chinese contract manufacturers. Using theories and methods learned from Maskell, Hubbard documented that handles that were being manufactured in China at $6 a handle would cost $2 a handle to make at the Post Falls plant. The production was moved in house, and now the company uses the variable-cost model to plan production for all new products. (Such a model accounts for actual costs and value created, not just a per-unit price.)

Chris Potts, cost accounting manager at Buck, said the model evaluates three factors:

1) Capacity and headcount,

2) Material costs, and

3) Additional incremental costs.

“The whole premise here is to look at cash flow and see what the real cost is, not the estimated cost based on a model that you built back at the beginning of the year when you had certain assumptions,” Potts said. “In the past, we would have looked at a fully burdened cost regardless of whether we had excess capacity.”

Recently, using this technique led to the decision to produce a $1 million order in Post Falls instead of China. The result was a much higher profit margin, Best said, because Buck used assets it already had instead of writing a check to a contract manufacturer and paying related import and transportation fees.

New Model, New Metrics

As Buck was adopting lean accounting and ramping up lean projects at its new plant, it also invested in a new ERP system. This provided an important lesson learned that Buck mangers repeatedly cite: Don’t attempt to install a new ERP system while starting massive lean conversions. Wait until you are farther along.

Buck Knives has had to invest countless hours converting the ERP system from its traditional-accounting focus to value-stream/lean-accounting focus. The work continues. Potts is constantly refining the reports he produces for value-stream managers that document costs and profits. He does this in conjunction with lean process changes. For instance, the company is in the process of creating supermarkets at each value stream that will hold production supplies, some of which are used by everyone and currently are warehoused in a central location. The supermarkets will allow for more accurate capturing of supply costs by value stream and reduce the need for warehousing.

“Each year as we go forward, we’ll get closer and closer to having a true, actual cost for all of these things,” Potts said. “This will be the first year we’ll be able to take a look at this year’s actual versus last year’s actual. So we’ll be able to fine-tune our expectations.”

In addition to the finance-oriented measures, Buck is recreating is performance metrics. This need has arisen from both the cultural changes that have taken place and the obliteration of the old ERP system. C.J.Buck said this is where most of his focus as a leader is these days — asking not just what are the answers, but what should be the questions. When the new performance metrics are rolled out, they likely will be some of the most well-tuned lean performance measures created by a manufacturer. In so many ways like this, Buck Knives is an idyllic lean operation — a company that is building not just products based on lean principles, but a culture based on lean principles.

“This is a family business. It has a very specific culture,” Buck said. “I like the way lean invites you to share information because sharing information can help you. That strikes me as common sense. It also reinforces that I don’t want robots. Trained people are by far your best asset. And as people learn more and become more flexible, it adds flexibility and robustness to your operations.”