One of the challenges in getting sustained results from lean thinking and practices is understanding them as a system rather than just a collection of tools. Of course, many organizations initially apply lean tools to improve efficiency and reap significant improvements in the short term. But, unfortunately, such an approach only harvests the low-hanging fruit, as waste is everywhere.

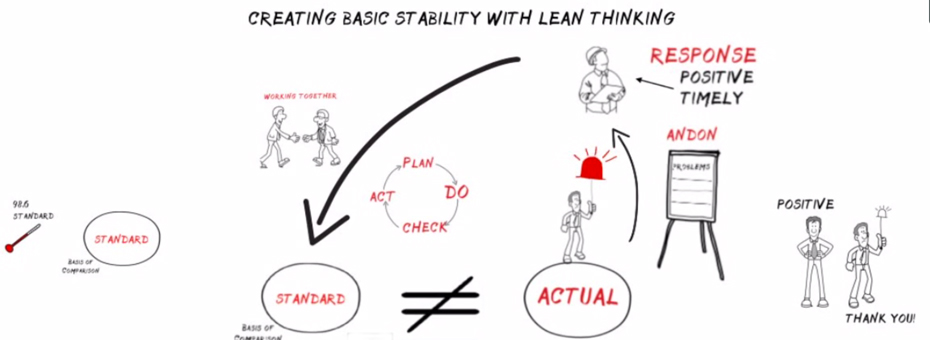

However, lean thinking and practices can change an organization fundamentally when leveraged as a system. I demonstrate this idea in one flipchart drawing when I teach workshops or speak to small groups. This lean-in-one drawing illustrates how the practices and tools work together with a management system and philosophy designed to support workers and help them be successful in their jobs.

Lean thinking and practices can change an organization fundamentally when leveraged as a system.

Recently, I turned my hand-drawn flip chart into a whiteboard video (see below) that will help you understand how to think about lean as a system and see the linkage between lean tools and how the system can create organizational advantage.

As you watch, pick one of your critical processes and ask yourself to what extent you have all the pieces of the system in place, as I have described. I bet you’ll find some missing connections that you can focus on improving.

Then share the video with others in your organization to help them better understand and use lean as a system to create basic stability and continuously improve your work processes.

What follows is a lightly edited transcript:

Hi, I’m Dave LaHote, and I would like to show you my lean-in-one drawing to help you understand the system for creating basic stability with lean thinking.

Lean Thinkers believe that all work is accomplished through a process, and for every process, we should have a standard. It doesn’t matter whether we’re talking about manufacturing processes, like assembly or production, or administrative processes, like customer service, engineering, or registration. We need to have standards for these processes — standards around items like safety, quality, timeliness, and cost.

Here’s an example to think about: What is the standard for body temperature? Ninety-eight point six degrees, right? Does this mean that everyone must have a body temperature of 98.6? No. It’s a basis for comparison. Without the standard, we wouldn’t know when we should take additional action. So, a standard is a basis for comparison, so we can tell abnormal from normal and proceed accordingly.

Lean Thinkers believe that if you establish and follow standard work, specific job instructions, and methodology, your process should produce the expected outcome or actual that is equal to the standard.

But we know things don’t always work as they’re supposed to. And when we get an actual that does not equal to standard, we have a problem.

When we have a problem, what should the people doing the work be able to do?

They should be able to ask for help.

Now, most of us have heard how on an automotive production line, if a worker experiences a problem or abnormality, they are expected to pull the cord. And pulling the cord sets off a signal like a flashing light. This signal is called an andon.

Most of you probably do not have cords hanging around your workplace. But there are many ways to signal for help.

In manufacturing environments, perhaps you have a production-by-the-hour chart. In a hospital or an office setting, you could have a whiteboard or flip chart where the workers can write down the problems or abnormalities they are experiencing.

So, if the worker experiences a problem and signals for help, what should happen?

Of course, they should get a response from their supervisor or the designated andon responder. And they should get this response in a positive and timely manner.

If someone asks for help and we respond by saying something like “What’s wrong, now?” likely, they won’t ask for help again.

So when someone pulls the andon, signaling for help, we need to say thank you.

Our response needs to be a positive experience for the worker.

Well, how fast should we respond when someone asks for help?

Here’s an answer that could make you a famous consultant. The answer is: it depends. It depends on what is needed for that specific processing problem.

On the automotive assembly line, where they produce a car every minute, the response must take place in a few seconds. Otherwise, the assembly line will stop, causing the loss of the value of a car every minute.

A production-by-the-hour board, by definition, needs to be checked or responded to every hour. However, a whiteboard or flip chart in an administrative area may only need to be checked once a day.

The response time required depends on what has been agreed upon for that specific process in the andon system. What is really important to remember is that the agreed-upon response time is a promise to the worker by management. Never promise something you can’t do. If you say you will check a board every hour and don’t keep your promise, workers will stop following the andon process, as they’ll just see it as a waste of their time.

Once we respond to the signal for help in a positive and timely fashion, we need to work together to solve the problem and take us back to the standard.

Notice I said work together.

Too often, the typical approach is for the supervisor to go into firefighter mode, where they come in and save the day by telling people what to do. While this might solve that problem, lean thinking tells us we need to create organizational capability for solving problems. Therefore, no firefighting.

Instead, the supervisor needs to work with the worker and teach using a problem-solving method, like the plan, do, check, act (PDCA) process, so that, whenever possible, they can coach the worker into solving the problem themselves. This approach will create the organizational capability that can lead to competitive advantage as the workers become more capable of solving problems and producing good results.

And wouldn’t it be nice if we could see abnormal from normal right now? That’s where visual control comes in, where we put our critical processes and visual control so that abnormal conditions become apparent and easily recognized.

So for all our important work processes, we need a standard that helps us define what we need in terms of metrics measuring and tracking safety, quality, timeliness, and cost. This standard is a basis of comparison versus an absolute. We need good standard work established so that the workers can be confident that they can produce a good result. But stuff happens. So we need visual control to enable everyone to see abnormal conditions and problems. And once an abnormality is detected, we need a system for signaling for help. When we signal for help, we need to get a response in a positive and agreed-upon timeframe. Our supervisors need to work together with the worker coaching them through the problem-solving process that will bring the process and results back to the standard. It is this entire system established and working that creates basic stability in our workplace. And this is the system’s thinking that underlies lean.

The mistake that many organizations make is that they implement specific lean tools without an understanding of the need for a closed-loop system. So, for example, they might do Five S to create visual control but have no standards or andon system. Or maybe they put in place a sophisticated andon system but have no proper, consistent response method. Or they preach teamwork and problem-solving, but they condone and even encourage firefighting by their supervisor.

One needs the entire system. In fact, one can actually do the individual pieces poorly as long as the entire system is in place.

So how are you doing in your organization? How well is your system working? What pieces are you missing?

Editor’s Note: This Lean Post is an updated version of an article published on February 15, 2017.

Key Concepts of Lean Management

Get a proper introduction to lean management.

Very nice and simple rendering of the system that applies to all processes and work product for building capability!