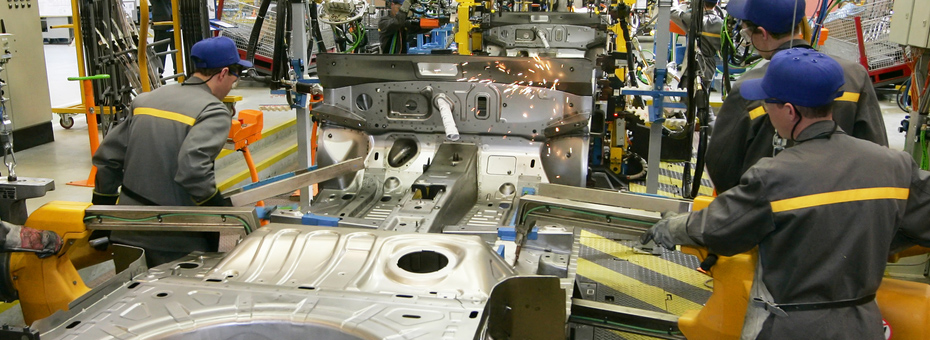

This is a real story of Jeff (Labor Rep) and Bob (UAW) on a shopfloor call and the “Customer First” principle, also known as “building quality in station.” Jeff (Labor Rep) and Bob (Union Rep) work in a car and truck manufacturing plant. The standard routine is for the Labor Rep and Union Rep to investigate the cause of a problem jointly, then seek a solution at lowest possible level. This is called the “Problem Resolution Procedure.”

This story takes place in Frame One, Chassis Truck Line. The work is this: gas tanks are loaded into truck frames. The problem is: the team member on the job is not able to verify the tank number with the frame manifest coming down the line. By looking at the manifest code and the number on the tank, the team member verifies the correct tank. But the wrong types of gas tanks are being installed into the frames for a reason that needs investigation. The frequency of wrong tank installation is 6 tanks per shift, and the severity of repair is 4 minutes of line shut down or disruption (line moving every 1.5 minutes). So this is a pretty big deal!

Bob and Jeff observe and investigate the hand motion of the team member who is installing tanks (Doug). His hands pause as he struggles to match a tank with the manifest. Bob asks WHY? Team member Doug says the manifest does not match the color of the wire on the tank as it should. Line supervisor Anita agrees. Bob asks how many types of tanks there are. Doug says 16. Jeff says they need 16 distinct codes/colors on the manifest to make a right selection from the tank part area. Doug says that would be nice.

Bob asks how they know they are putting on the right tank each time, because they get all but 4 each shift. Doug says that is not exactly true: “We catch about 20 wrong ones inside the process step itself.” Jeff, Bob, and Anita observe the process for several hours. The severity and frequency are much higher that previously thought.

The observation process reveals that only 8 tanks have clearly visible/readable colors on the wires. Remember, Doug uses color to identify and match the tanks up with the manifest code to confirm they’ve got the right tank. The other 8 tanks do not, which leads to the problem of wrong selection. The tanks come on a cart in the order they are needed to match what is coming down the line. Max from Production Control loads the tanks to the rack. Anita tells Doug they come in the wrong order or are just flat out the wrong types of tanks.

Anita, Bob, Jeff, and Doug go back to Production Control to see Max. Max says he reads a print out and loads the tanks onto the rack for Doug: “I read the numbers on the print out and select the right tanks to put on the dolly in the order they are needed. That way the color matches Doug’s manifest.” He goes on, “Heck, I can’t read the codes from the supplier on those 8 tanks, but the other 8 tanks are easy to read. If I can read the number, then the right color tank wire (and tank) make it on the dolly in the order they are needed.”

Bob asks WHY can’t you read them? Max says the print code comes damaged, plus the color is on the underside of the tank. The print code (when it’s readable) enables Max to match the tank with his schedule print out from production control. Then Max loads the tank dolly for the customer so the tanks match the frame manifest that the customer reads to verify their correctness.

Everyone looks at the print out Max has to read and the color code on the tanks. All agree that no one can read the codes to match the print out. The supplier label machine is not printing clearly, it’s damaged. Bob inquires, “Before we get that fixed at the supplier, what can we do TODAY?” Colors are marked is on the wires of each tank, but the tanks are upside down. Max would have to lift each tank to verify the wire color if he can’t work with a clearly printed label.

Max says there is a colored wire on the underside of the tank, but the tanks are too heavy to lift up to read (the tanks come in the dolly right side up). Back on the assembly line Doug uses a hoist to lift and load tanks into the frame. Anita asks Max, “Can we load them into the rack for you upside down so you can see the right color?” Max says, “Yes, I can match the color to a code to ensure the right sequence to Doug.” Sherry the driver says, “No problem. We can load tanks to racks that way off the truck.” Production Control Supervisor Andy agrees: “We can just make a chart so that the color and barcode match. We can get the right sequence to Doug at the line.

Next, Bob asks, “How soon can we try it to see how it impacts Max and Doug?” Sherry suggests they go load an hour worth of tank to see if Max can pick them and Doug can assemble them using the new process.

Bob and Jeff help Sherry load 7 test carts (84 tanks). Bob says when he gets home he may just pass out for a few days. Jeff tells Bob to stop eating Burger King every day. Bob tells Jeff to shut up, and to go slug some more tanks into Sherry’s carts for Max.

Everyone conducts the trial an hour later for two hours to test and verify if Max (PC) and Doug (line) can select and install the right tanks to avoid the waste of having to correct the process (rework): removing the wrong tanks and reinstalling the right ones. But there are no errors. Max selects the right tanks for Doug, and Doug can verify the color on the tank wire to match the color on the manifest. Jeff and Bob conduct this trial with the team for a day or two, and the test is established as the new permanent process until the supplier makes the necessary correction.

Bob tells Jeff that in the old days a grievance like this would be filed and nothing would have been done to the actual job (management may just add more labor). Of course adding cost never works and besides, this wouldn’t lower the frustration level of the people doing the work. They know they need to involve the people doing the work in creating a real solution and work with their ideas to resolve the issue.

Max and Doug write up a suggestion about jointly solving the issue. They receive a financial reward for the improvement. The improvement leads to a cost of avoidance annually calculated to be over a million dollars of line shutdown idle labor and lost vehicle revenue. Bob and Jeff made sure the people doing the work who came up with the improvement ideas receive the benefit.

This is an example of a Lean Labor Relations procedure and teaching the “Customer First” principle through working in collaboration with others to identify and solve a real problem. Each day calls come into Labor Relations. The Labor Rep and Union Rep team go out to see first hand what is happening together and to investigate what experiment is needed to resolve the issue at hand. In this case the next step was the internal customer, Doug. If Max didn’t produce (convey) quality then Doug and his line had problems that impacted the entire system. So, in essence the team practiced the lean “Stop, Do Not Pass Defects On to the Next Step” principle. The problem was identified as soon as possible and a potential remedy was tried asap. As a result, over the next month very few wrong tanks were installed.

Bob (the veteran) continues to train Jeff nightly by leading through example, except at lunch. Bob tells Jeff its time for lunch and they go to Burger King. Jeff says “Bob they have salads here.” Bob replies, “Great, you eat them.”