Atlanta firm embraces lean in challenging industry with multiple gembas.

At HighGrove Partners, an Atlanta landscaping company, lean is making inroads into a service industry in unusual yet fundamental ways. For example, you won’t see the gamut of lean tools used by employees in the company or even lean used by every employee in the company. But, more importantly, lean thinking is embraced by HighGrove leadership and management — despite initial and intermittent setbacks — and gradually working its way down through the organization and to the bottom line.

HighGrove Partners At a Glance

- Founded in 1989

- One of the largest privately owned diversified landscape design, installation, and maintenance companies companies in Atlanta, GA

- Provides a range of landscape services to office parks, commercial buildings, institutional and community operations, and private residences.

HighGrove consists of three units: a maintenance group that maintains commercial landscapes (mowing, trimming, edging, etc.); a design/build/enhancement (DBE) group that takes existing landscape plans, specifies plants and hardscape (e.g. stonework, boulders), and executes the installation; and an architectural group that designs landscapes. The groups are headed by partners Jim McCutcheon (chief executive officer), Ken Rogers (president), and Bill Lincicome (chief creative officer).

Lean seeds were sowed at HighGrove by mower supplier Ariens, landing first in the maintenance group and office and administration departments and more recently in DBE. The two units were logical targets, since maintenance and DBE together account for about 90% of HighGrove revenues and the majority of labor — 17 maintenance crews (most with three persons, including a supervisor) and three DBE crews of four to six people each.

McCutcheon had attended a national landscape meeting in 2004, during which equipment maker Ariens gave a presentation on its lean practices. McCutcheon wanted to learn more, so he, Rogers, and other industry leaders spent time working on the Ariens plant floor. “We spent a week, learned a lot, came back, and dabbled in it. We weren’t ready for it,” McCutcheon recalls. Despite the interest by the partners, back in Atlanta lean was competing with other internal ideas and had not been exposed to staff.

Yet HighGrove continued to have operating problems, and McCutcheon and Rogers continued to think about lean. “We saw that there were opportunities to make improvements,” says Rogers. “We were not getting the results we were looking for, both financially and quality.” The partners then sent Chris Anders, newly appointed director of continuous improvement, and a team to Ariens to be immersed in lean. In May 2005, Ariens led the first of two kaizen workshops at HighGrove, and other HighGrove-led kaizens soon followed. Lean was beginning to sprout.

Getting more staff involved was key, says McCutcheon, because employees were able to recognize the value in lean relative to their own work rather than merely taking his word for it. “It’s helped me to see a lot of things differently, too. At times we’ve had frustrations with it and things didn’t work out like anticipated — and I know that’s absolutely normal — but I’m extremely happy we did this process and are continuing to become a lean company.”

Anders credits McCutcheon and Rogers with sticking to lean despite initial challenges. “Even when we had those disappointments and frustrations,” Anders says, “we knew we were continuing with it. It was faith in the journey, and that got people past that point where they were expecting it to go away. Our owners have done a good job of staying the course and supporting it. If you don’t have that backup, it would make this next to impossible.”

Uncovering Processes, Defining Standards

Landscaping is a contrary industry for an improvement approach that relies on standardization. HighGrove has more than 300 maintenance job sites, each subject to changing conditions based of weather, time of day, soil conditions, work crews, plant materials, and season. Simply identifying any standard can be challenging. Landscaping job sites make manufacturing plants look like “laboratories,” says Anders.

“One of the first reactions is, „Can a service company really employ these strategies and see some savings?’” says Rogers. “It took me and everybody some time to get our minds wrapped around how do you employ these things in a service company. Jobs sites are all different. The processes can be the same — mowing is a repeatable process — but every site is different. So as you relate it to a manufacturing line, it’s not that easy.” HighGrove kaizens are designed to uncover processes amid the variability, develop standardized work for those processes, and then begin to apply lean concepts to remove waste and improve the process.

Each day begins with the critical process of getting crews prepared for the day and out to job sites. Shop departure is a major source of waste for many landscape companies. In Atlanta, a small delay can mean getting stuck in rush-hour traffic. At 6:15 a.m., maintenance supervisors and crews gather around a large circle in the main HighGrove facility (HighGrove also has two satellite locations). At a morning “stretch” (more a euphemism than actual exercise session) prior to the scheduled 6:25 a.m. departure, operations managers (OMs) discuss topics for the day and address reoccurring problems. The sessions allow the four maintenance OMs to reinforce lean ideas, such as assessing job sites and removing wasteful activities.

“One of the things we found out early on is that we were mowing, edging, and blowing every single job, every single time,” says Anders. “The reality is that turf doesn’t always need to be mowed, edges don’t always need to be done. That’s waste. Let’s only mow when we need to. Let’s only edge when we need to based on our customer-value statement. Value is anything that physically transforms the property more in line with the customer’s expectations. So if we weren’t doing that, it’s waste.”

When crews focus on routine rather than customer value, they can miss details that a customer notices, such as an untrimmed shrub in a high-traffic area. This particular morning an OM reminds supervisors to remember detail work and make on-the-job decisions about what needs done. “If you’re not sure what to do, call your OM.”

By 6:25 a.m., all but one of the crews has hit the road and dispersed to job sites around metro Atlanta, their out-of-shop performance recorded on a board near a large clock. “It’s pretty simple,” says Anders. “Red (exit time) if you don’t make it, and green if you do. It’s funny how little things — or big things — like this clock make a difference to people. As soon as we put it up, people paid more attention to what time it was.”

Boosting Productivity Once at the job sites, HighGrove’s challenge was and continues to be determining how much standardized work is applicable or desirable. Do you attempt to define how every labor detail is performed, as you might do in a manufacturing cell, or pursue a broader form of standardized work?

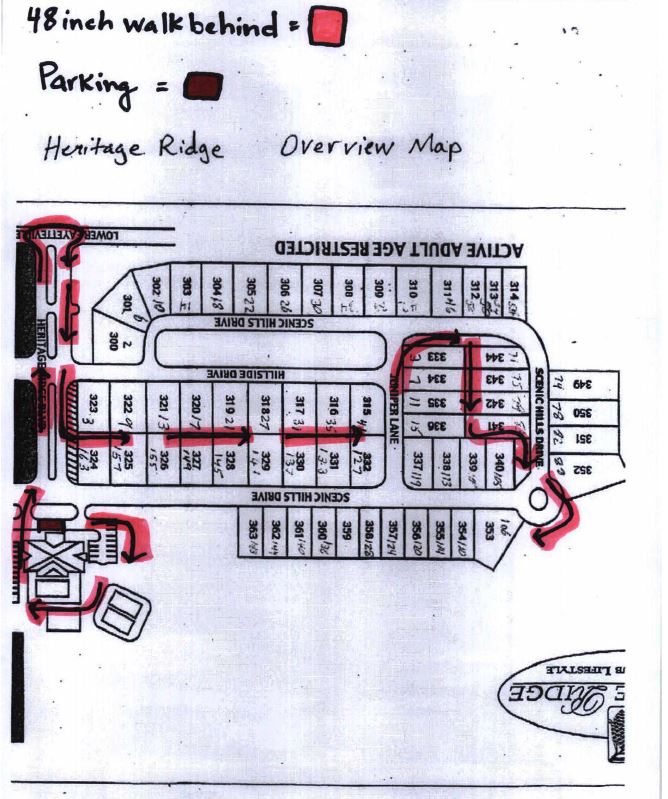

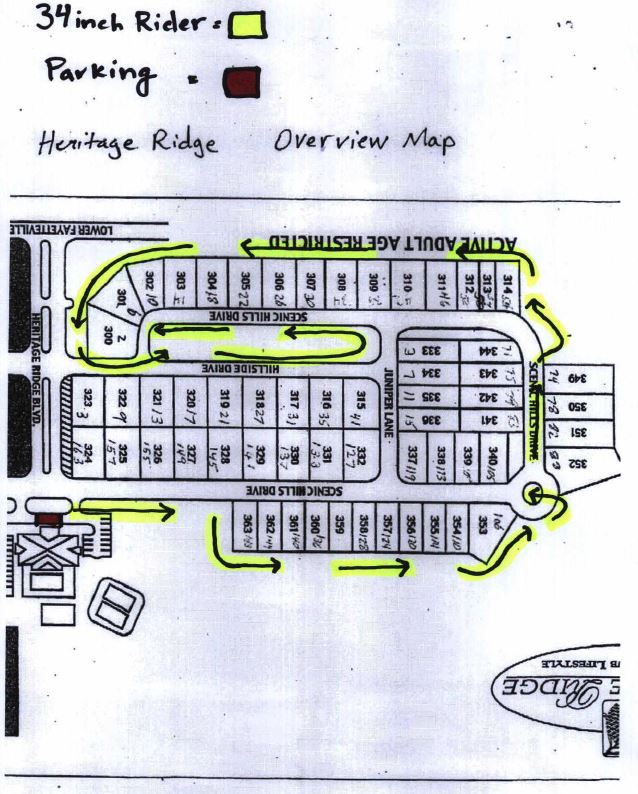

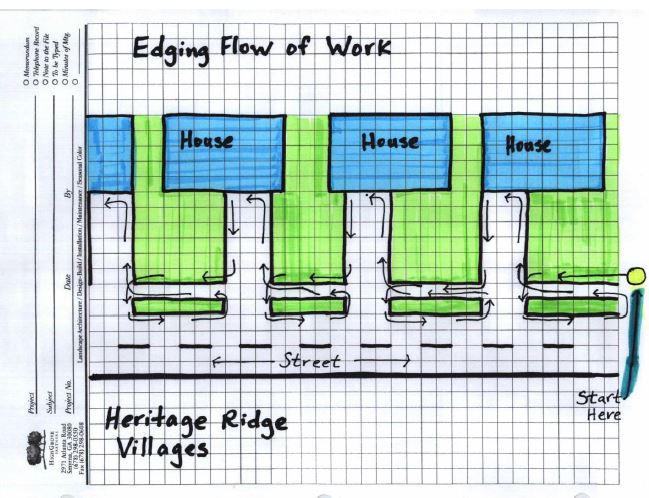

“We talked about the variability of our product with 330 jobs, and trying to map that and [apply it to] mowing, edging, blowing, and detail work,” says Anders. “I didn’t think we could generate enough of that quickly enough, and have it be understandable enough that people could follow it. So we talked more about best practices and a more basic map. Properties are different from each other, and the same property is different based on what’s going on with weather, horticulture. Trying to write standard work for the middle of summer won’t work for the middle of winter, but general flow can. So we generated property maps in that vein.” The maps are brought to job sites and detail activities, such as where to park, where to begin, what mower to use, and the course to follow for mowing and edging, if mowing and edging are required that day (see the flow maps below).

Four maintenance crews arrive at a 60-home residential complex where flow mapping and design-of-work improvements have boosted productivity. In June 2007 the property required 56.2 hours per week to maintain vs. a budget of 36 hours. Gary Tomlinson, director of maintenance, helped an OM revise work flows and equipment after conducting time-and-motion studies. The changes reduced job times — 35.9 hours per week vs. budget of 33.75 hours — and reduced the walking, workload, and fatigue on laborers. The improvements reduce costs as well, even when the purchase of new equipment is computed into margins, says Tomlinson. Repeatedly eliminating waste on the job also allows HighGrove to incorporate improved performance into budgeting and proposals (i.e., more aggressive pricing).

The DBE group recently has begun to follow many of the actions taken by maintenance, starting with a kaizen that focused on improving efficiency of morning operations (preparation and departure), designing standard work for morning and afternoon activities, developing visual tools to track improvements, and applying 5S to truck and equipment storage.

“Going through that kaizen back in March has been a huge benefit to our department as far as efficiencies being so much better,” says Kevin Hambrick, DBE project manager. “Everything we’re doing is a little better, and our margins are getting better because we’re so efficient on our job. It was a huge payoff.” Results from the kaizen will now be implemented across the entire DBE division.

HighGrove management admits that it must work to keep OMs focused on lean and standardization, especially as they look to OMs to help with the next phase of lean — engaging crew supervisors with lean concepts. Supervisors may be responsible for 50 different job sites, and simply getting them acquainted with sites — let alone standardizing work there — can be difficult, notes Rogers. “It’s one of the big challenges of having gembas all over the city as opposed to just out back. How do we do some [kaizen] observations, take some best practices, put them in place on every job, and then figure out a way to ensure that.”

Putting standardized work in the hands of supervisors, through training, certifications and using OMs as trainers, can multiply the number of lean minds in the company. And, says Tomlinson, this will enable supervisors to be the ones advancing the standards. “There are a lot of things that a supervisor will do on every job. When they get to the job they look it over and assess what they need to do, and that’s where the lean principles come in. We are starting to see a little of that happen with supervisors.”

Manufacturing-Like Lean

A few lean initiatives at HighGrove are comparable to manufacturing improvements. None more so than a large power-equipment area that is run by Gary Nelson, the fleet mechanic who oversees equipment and vehicles (fleet-management schedules, insurance claims, etc.), and Barry Cole, responsible for maintaining mowers, edgers, blowers, and power tools.

Prior to kaizen events there, power equipment parts were disorganized and lacked a process for ordering, stocking, and identifying their age, making it difficult to manage inventories and identify reorder points. “We had no stock points,” says Anders. “We had nothing. We had no way of telling how old stuff was. We would know how they’re doing when the invoices came in. ” Goals were established to organize stock, establish order points with a kanban system, devise a method to track the age of parts and refine order points, and develop a process for purging unnecessary stock.

Out of the first kaizen, HighGrove was able to sell “a pile” of parts. HighGrove no longer operated equipment for many of the parts and redundant parts included 35 fuel filters where two were sufficient. Other improvements included fewer and better-labeled parts shelving, easier access to tools and parts, floor lanes to define working areas, standardized color-coding for aging of parts, standardized work/repair checklists, floor kanbans for vehicle and equipment dropoffs and pickups, and audit forms to ensure adherence to the new standards and 5S.

“It’s been a big change, but a very positive change,” Cole says. “It’s a good work area. I’ve been in a lot of shops, and I’d put this No. 1 with any. I don’t think you’ll find any better than this. And kaizen has helped that and helped us understand more.”

“Greg and Barry have understood it, found the value in it, and continue to improve on it,” says Anders. “Often when we have a kaizen, I feel good if we can just hold on to what we did during the kaizen. They continue to add new things to their 5S, new checklists that are posted on a lift — just standard work.” More than a dozen other kaizens at HighGrove are reaping benefits, including:

- Financial statement process: This kaizen tackled the accurate and timely delivery of financial statements. The department was plagued by errors and delays, and goals were set to reduce cycle time of financial statements from 22 days to five days and reduce critical errors from seven to 0. The kaizen team discovered excessive handoffs and repetitive (yet ineffective) checks for accuracy. Standardized work was introduced to reduce process steps and errors and allow for more automation, such as moving from hard-copy timesheets to electronic timesheets, which incorporate drop-down lists and built-in calculators. The electronic sheets save about 75% OM time and a day of accounting work per week because they export into the financial system (i.e., no rekeying). Monica Sanchez, accounting manager, says standardized work for staff also has enabled individuals to pursue more activities independently, which in turn provides more “touch points” for the department.

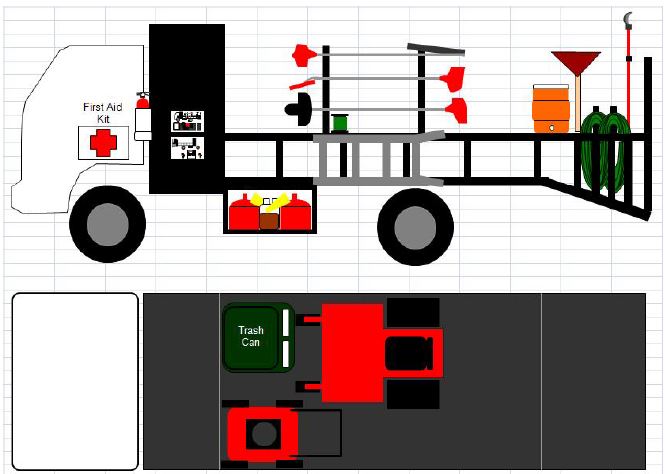

- Maintenance fleet 5S: This early kaizen led to many job improvements, including laminated maps of maintenance trucks that are attached to the trucks and show standardized storing of mowers, edgers, and tools (see the truck 5S layout on the next page). And 5S of trucks reduced the number of blowers carried from three to two, without any negative impact to field work, resulting in 30 fewer blowers for HighGrove to own and maintain. Similarly, shears were removed from trucks because most trimming should be hand-pruning (shearing promotes excessive, unsightly growth and more trimming).

Accountability

In mid-2006, many kaizen improvements at HighGrove began to wilt, despite solid implementations of lean basics and standardized work, says Anders. He and others realized there was a lack of accountability, “not just lean accountability, but general accountability.”

“One of the big „ah ha’ moments was eight months to a year into it,” recalls Rogers. “We had done a couple of kaizen events and hit a crossroad. We had stuff on a 30-day list, new procedures, and stuff wasn’t getting done. We realized it wasn’t that the kaizen was bad or the conclusions drawn from it were bad, it was just that we were not holding our people accountable to do it … We have to execute it.”

In the fall of 2006, “accountability” was the theme for HighGrove’s management retreat. Soon thereafter, HighGrove began a version of the Working Smarter Training Challenge, developed by JP Horizons and Ariens. For one year, 25 of HighGrove’s management met weekly for about an hour on company time to learn about lean. “That really spread all the tools and processes out and let everybody see what they were about,” says Hambrick. “It gave us takeaways. That was huge. It gave everyone a different perspective, and made it easier to take out to the field.”

“We’d take things and tackle them a small amount at a time,” remembers Sanchez. “We spent two or three weeks on 5S and what that meant, and we’d have homework assignments [and work-related projects] from it. It was all things that were kept small, and you could fit them in your schedule. It really helped you understand and fully learn that concept.”

By 2007, a broader group of employees believed in lean. “People’s „belief windows’ started to open. They’d seen results. They might not always agree with it, but they were going to give it a shot,” says Anders. Lean was truly growing, moving from a HighGrove concept to culture.

“It’s what we do every day,” says Hambrick. “Listen to the terms that people are using now. It’s part of common conversation. It’s a process and something that everyone has to buy into. The company has done a really good job of continuing it with Chris being here. We’ve got somebody that can drive it that is 100% committed to it. I’m sure he’s not been the most favorite person at some point, but change is change.”

“Resistance has gotten light as time has progressed,” says Tomlinson, a Marine who was hired in 2007 and brought in industry credibility coupled with a standardization background and an awareness of lean; he works with OMs at applying lean tools, adhering to standards, and identifying waste. “Like Chris says about the belief window, once they can start to see results from [lean], you get them to believe in it. That’s what you don’t see from other [improvement] programs. They’re just a program.”

Paul Leao, director of lean resources at mower supplier Ariens, says many landscape companies try lean, but like in other industries there are a percentage that get it and those that give up. “You’re going to see a lot of organizations start the journey, but then they’re going to waver at some point. There’s just those rare few that continue to hold onto it and, in fact, drive it throughout the organization. And HighGrove is one of them. Those that make a commitment to hiring a lean manager, those are the ones that are getting it. Those are the ones that are going to make it happen.” HighGrove also is unlike many landscape firms in that it’s been willing to apply lean beyond office or shop areas to the job sites (“where the cash register rings”) and gone beyond 5S tools and “basic building blocks,” he adds.

Lean has given HighGrove the means to address challenges as they arise, says Rogers. “When we’ve got a problem, let’s go through and analyze the process and make sure it works right. Write standard work and put it in the right place. Put controls in place to make sure it’s executed and we have some way of tracking that. [That] was typically missing in our company: lots of great ideas but not a whole lot of execution, not a whole lot of accountability.”

HighGrove goal-setting has helped enforce accountability and shaped clear performance targets. “One of the things that we realized was that we had not done a good job defining what a win is for the company and what a win is individually,” says Rogers. “How

everyone’s individual goals feed back up and support company goals.” Now managers within departments have goals that support the department, and department goals support the company. At the end of each month each, managers receive a scorecard that shows how they’ve done toward their individual goals, and those scores are annually tied to a bonus system.

“It’s very difficult to sweat [goals] down into five or six things,” says Rogers. “You don’t want too many because people get confused, but you want enough goals and the ability to quantify them so you can clearly define what a win looks like.”

HighGrove has defined a corporate win for 2008 as $11.4 million revenues and $2.55 million contribution margin (defined by HighGrove as revenue less direct job costs and controllable overhead), and these targets as well as financial results are transparent to employees. HighGrove goals and mission are visually represented with a diagram of a flywheel (a machine component that stores energy mechanically and distributes it to an engine). At the center of HighGrove’s flywheel is Customer Focus, and the four points connecting the center to the rim are Service, Quality, Profit and People. “Once the flywheel gets started, it’s hard to stop,” says McCutcheon, noting that if it’s not perfectly balanced, it destroys itself.

In Atlanta these days, it takes a well-balanced and continuously improving landscape operation to stay in business. The $8 billion landscaping industry has lost $3 billion and 35,000 jobs in recent years due to the Southeast drought, says McCutcheon, and faces rising internal costs and stagnant pricing. “We’re getting squeezed from both ends of the spectrum. But at the same time we’re not going to give up on the values we have as a company of providing good quality and service to our customers. So how do you make that happen? Lean for us was the answer to make that happen. We’re going to have to continue down that path, whether we wanted to or not. We don’t have much of a choice. We need to do that to achieve the goals we want to as a company, and we feel that lean serves the values of our company as well.”

McCutcheon sees other landscape firms attempting or considering lean, and advises them that traditional lean is not a pure fit. “We took the core values out of it, and use many of the tools and modified a couple of the tools, but at the end of the day we’re still eliminating waste. The purists might not like where we’re at, but it works for the business.”

For More Information

High Grove Partners — The Atlanta landscaping company has three units: a maintenance group that maintains commercial landscapes, a design/build/enhancement group, and an architectural group that designs landscapes.