Weeks after police searched the factory kitchen of 365, a chain of 100+ bakery-cafes in Barcelona, looking for a basement hiding illegal immigrants, owners Juan Antonio Tena and his wife, Emi Castro, finally learned the truth behind the nighttime raid.

They discovered that a “tip” about the nonexistent basement had come from competing bakers, convinced that 365’s small commercial kitchen couldn’t possibly supply a chain of retail stores with high-quality products unless it had illegal immigrants hiding underground working 20-hour days for low wages.

“Instead, what we had was an amazing system to organize our work – in plain view,” they said.

The system, based on lean management principles, gave 365 formidable competitive advantages, including:

- Dramatically improving productivity so it could supply coffee and a variety of baguettes, ciabattas, croissants, pastries, sandwiches, and cakes to more than 100 retail bakery shops from a kitchen designed to support 60 to 70.

- Reducing retail store staffing from three or four people to two in most cases, while improving service.

- Engaging employees through a company culture that encouraged identifying and solving problems.

- Improving processes so more and more products could be made in retail shops instead of the central kitchen, cutting the complexity and cost associated with baking, packaging, and transporting products from a central location.

Keeping Up with Customer Expectations about Food

The owners believe that this last improvement gives them an additional competitive advantage because it puts food creation processes in full view of retail customers.

“Customer expectations and the culture around food are changing,” the owners write in their new book, The Lean Bakery. “They want to know what goes into the food they eat, and who could blame them? In the new 365 shops, there will be no secrets, no more bread made in the back of the shop or in the factory … just healthy product made two meters away from the point of sale. Our idea is to go back to the old-fashioned way of making bread, one that will remind customers of when they were in their mother’s kitchen.”

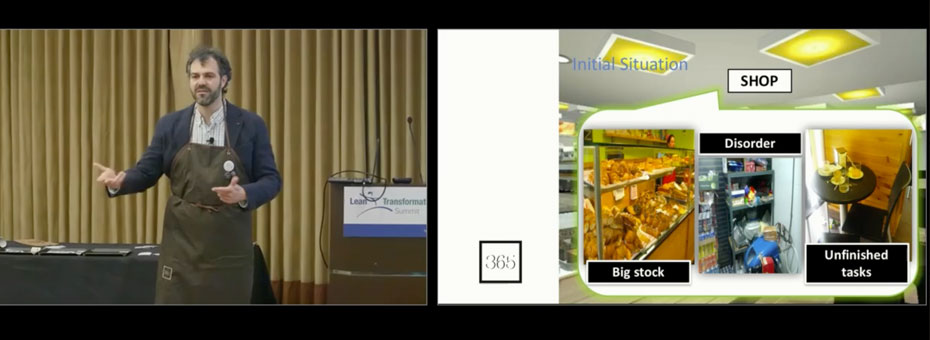

In a candid, detailed video Agus Tena, 365’s continuous improvement manager, and Oriol Cuatrecasas, an engineer at Instituto Lean Management Spain, take you through the transformation’s cultural change and lean tools. Learn how this chain of bakeries and retail stores used lean continuous improvement to profitably expand, engage employees, and meet growing customer demand for healthier products.

Video Timeline, “The Lean Bakery – Better Customer Service Through Problem Solving”

- 1:44 – 365 background and reasons for the change

- 7:00 – Objectives: Great prices and quality, create value, improve service, customer acceptance

- 15:17 – Lean production experiments begin with small batches to improve existing kitchen processes rather than expanding the physical kitchen

- 20:45 – Moving bakery production from a central factory kitchen to retail shops

- 26:05 – Simulation and analysis of the how shops operated

- 45:28 – Introducing standardized work, takt time, 5S, and other lean principles to cafes

- 1:04:42 – Culture change

- 1:11:53 – Results

- 1:13:05 – Competitors’ disbelief leads to the police raid

- 1:15:34 – Manual human resources board for open positions

- 1:18:25 – Reflections

- 1:20:07 – Q&A

Learn how this chain of bakeries and retail stores used lean continuous improvement to profitably expand, engage employees, and meet growing customer demand for healthier products: