What is hoshin kanri? In the excellent The Toyota Engagement Equation, authors Tracey and Ernie Richardson describe it as “the collaborative process for designing and deploying the goals and objectives that constitute management policy.” They trace its name by sharing that, “Hoshin is Japanese for ‘policy, plan, purpose, or target,’ while kanri represents the phrase nichijo kanri, which means ‘daily, normal, or regular.’”

Simplicity, simplicity, simplicity! I say, let your affairs be as two or three, and not a hundred or a thousand; instead of a million count half a dozen, and keep your accounts on your thumb nail.

Henry David Thoreau, Walden

This careful approach to sharing goals and ensuring the mindful realization of them grounds good Lean practice in a mindful and disciplined manner, and successful execution calls for consistent practice that draws from many core methods.

According to Mark Reich, hoshin kanri is “a mechanism, a management system that allows the organization to quickly and effectively adjust its priorities while engaging the team.” As a long-time Toyota employee, Reich experienced the power of hoshin as a means of tackling a series of challenges facing the company, including the great recession of 2008, a quality crisis, and a tsunami that fractured the company’s supply chain.

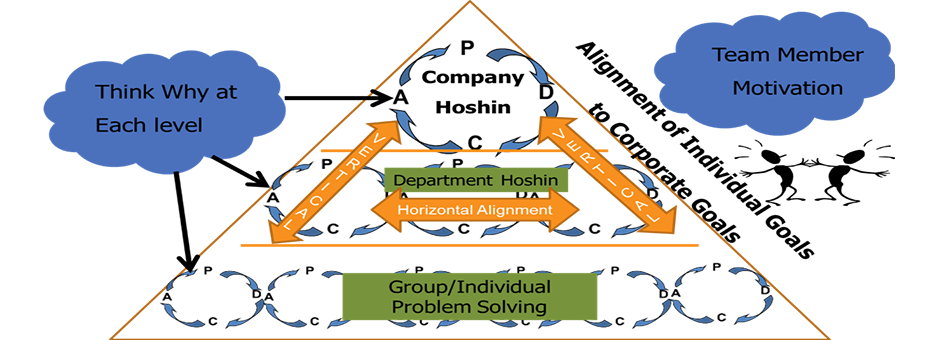

Reich shows how Toyota North American used HK as “a systemic approach for defining a strategy, and, more importantly, a management system that engages all people to support that strategy while building horizontal and vertical alignment” during his time. Specifically, it helped people to “feel the need” for change and become a self-reliant, team-oriented organization that operated more independently from Japan but as a single unit in North America.

His article shares a great overview of HK’s promise, rooted in one individual’s experience of this broad system used to build teamwork, develop capabilities, and frame problems in ways that boosted their potential to be solved by at the working level in a mindful manner.

Translating Plans Into Sustainable Results on the Front Lines

Hoshin informs and organizes planning and deployment at many levels simultaneously: the genius of seamless hoshin rests in its fluid guidance in matters both large and small. In The Cascade of Hoshin, Jim Womack describes how grand strategic goals established at top leadership levels align the deployment of myriad plans and projects throughout Toyota, where Hoshin is the development of “management mechanisms necessary to translate high-level hoshin plans into sustainable results on the front lines.”

By accepting the “Mobility 2.0 challenge” as the animating spirit driving countless experiments at all levels, the company could then drive the design of projects and actions ranging from the development of new batteries for elective vehicles, to partnerships with ride hailing and logistics firms, to greater connectivity (enabled by next-generation software) between vehicles, passengers, and their environment.

One huge takeaway from this piece: hoshin is defined as the deployment of the plan rather than the raw vision itself; and the key to success rests in the quality and number of experiments that are borne out of this process; numerous experiments, many of which will indeed fail as part of the broader process.

Of course one cannot address HK without reflecting on the culture in which it is expected to take root. As Tracey Richardson shares in Catchball Helps Us Get Past We Versus They, healthy organizations consciously operate in a manner that lets employees know that their organization has their best interest at heart; and that they are expected to come to work every day with the best interest of the organization at heart.

“A modern lean organization that focuses on processes, not only results, will get more buy-in from team members. Pro-active thinking on everyone’s part gradually becomes more prominent in the culture than defensiveness, reactiveness, or disengagement” writes Tracey. And while she suggests catchball as an effective way to create constant dialogue between the people doing the hands-on work and those who are levels above them, HK is another structured manner fostering shared thinking, planning, and improving.

Hoshin Is Not a Planning Tool

Michael Balle has shared a handful of practical articles on hoshin kanri, which he describes as a tool to:

- Focus the organization on a shared goal

- Express this goal clearly to all leaders

- Translate this goal in objectives and involve leaders in planning to reach these objectives

- And hold leaders accountable for achieving these objectives

When it comes to practical advice on things to avoid, he suggests, for starters, that people refrain from narrowly defining HK as a process of setting direction: “Hoshin is not a planning tool. Its main purpose is to communicate the general direction top management seeks in a way that leaves both latitude to operational units to formulate their own plans, and to reveal difficulties so they can be helped.”

One useful way of thinking about hoshin is to focus more on the intended results than obsessing about “doing it right.” As in: be prepared for mess. Few HK efforts end up with clean A3s and clear initial agreements; the conversation that will emerge from healthy HK will almost certainly (and ironically) generate initial mess, confusion, resistance, and frustration.

One of the best ways to battle this is to keep your system as simple as possible, says Lean Management Instituut Director Wiebe Nijdam, in his excellent primer on How to deploy hoshin kanri successfully. “You should start wherever the problems you want to solve are, so long as there is a system for daily accountability in place and the boards are present at every level and communicate with one another across the organization.”

Nijdam also emphasizes the invaluable role of visual management in keeping the system together, sharing the right information to all the players in the most effective manner. He notes that in most strategy deployment implementations, “visual management and A3 thinking are used separately. What Lean Management Instituut has been able to demonstrate, in years of work and observation, is that the two should be used as part of the same, structured, system to identify and solve issues.”

Moreover, he emphasizes the power of clarifying the right problems—identifying shared organizational challenges and then translating these goals into tangible challenges that can be worked on. He also shares numerous charts detailing how organizations break down problems into practical challenges, organized by weekly targets. (Check out the excellent Two years of hoshin at the Dutch Ministry of Infrastructure for a detailed explication of the nuts and bolts of mindful strategy deployment.)

And finally, he offers the hopeful message that while HK represents an ambitious and systematic practice, by starting small and practical, thus putting into play a structure where team leaders at the lowest level can immediate spot and address problems, this approach can fuel a broader adoption of these healthy habits.

Managing on Purpose with Hoshin Kanri

Learn how to develop strategy and build alignment.