Spring Spotlight: Creating the Purposeful Enterprise

Explore the best practices and insights examining this essential element of lean transformation in this and other articles in this occasional series.

More than anything, hoshin kanri (HK) is a means of connecting the macro with the micro. This enables you to see the highest levels of organizational objectives being worked at the micro levels, and to understand corporate front-line (micro-level) capabilities, creativity, and struggles at the highest levels.

John Shook, 2013 letter about Policy Deployment

When Tracey Richardson worked at Toyota the company used its True North statement as a “guiding beacon,” she says. This clear articulation of purpose tied every single person’s daily work to a broader purpose, in both a general sense and in a grounded, operational manner.

Above all workers could sense a tangible–and essential–“Line of Sight” linking their work to the purpose of the company. In What is Your Line of Sight?, Tracey shares an example of how an effective True North definition creates that connection: “We will always put the Customer first, while making the highest quality product, at the lowest cost, in the shortest lead time, in the safest manner, all while respecting our people.”

This phrase steered away from being too results-oriented (such as aspiring to “be Number One in the market.”) Rather, its aspirational goals informed operating principles, and enabled people to visualize the key performance indicators such as quality, cost, productivity, safety, and human resources. Awareness of how they were performing on these areas drove the company to improve its processes; which in turn boosted the results that people focused on. Tracey calls this work “evolutionary, meaning that if you achieve the lowest cost, you can then raise the bar and continue to improve.”

Form a Tangible Link Between the Big Goals and the Small

Such clarity formed a tangible link between the big goals and the immediate work at hand. She adds: “Our Toyota True North allowed us to look at our own work as the business goals cascaded downward from the 50,000 foot level of the organization down to the 1000 foot level. It helped everyone articulate what they were doing, how they were contributing, and what they should be measuring.”

She shares five questions drilling down into how people can align to this True North statement. First, people needed clarity about their role in the organization—a deceptively simple question, and one requiring clarity from individuals and their leaders from day one. They must also define their work responsibility, clarify the purpose of their job, establish the concrete goals that guide their job’s purpose; and finally, determine the company goals framing this work.

She shares a personal example responding to each of these questions as they apply to her own line of sight as a problem-solving instructor.

This grounded process of linking basic questions about purpose to specific goals and metrics naturally links purposeful work to a company’s mission. When done right like this, HK clarifies the “infrastructure behind the culture in a truly lean organization,” she notes in Create Your Own Fantasy Island Organizational Culture.

Defining culture as essentially the values and principles, actions and habits, and character and destiny of an organization, Tracey explains how tangible methods linking performance to top-level goals create a complete system of improvement. “In order for an organization attempting to embed lean thinking to have any chance of succeeding, there must be a level of discipline and accountability for the actions of all team members at all levels and across all function areas.”

Mindful Management is All About Shared Problem-Solving

Mark Reich elaborates on this link in Why You Should Link Hoshin Kanri with A3 Problem-Solving, a detailed explanation of how mindful daily management is all about shared problem-solving capacity. He shows how an organization integrates daily problem-solving with a robust long-term-oriented management system, saying “The relationship between the management system and problem-solving methods—particularly the linkage between the two—is crucial to optimize organizational effectiveness.”

Specifically, combining the two improves how the organization plans what it does, executes on those plans, and continuously improves.

Tapping his experience working at Toyota, Mark defines hoshin kanri as problem-solving at the strategic, structural level, focusing on innovation and driving creativity. “Hoshin kanri is a system that engages everyone in the organization not merely as problem-solvers, but also as innovators,” he says. “Built on top-down and bottom-up idea generation system, HK pushes the organization to a higher competitive level based on innovative thinking across the organization.”

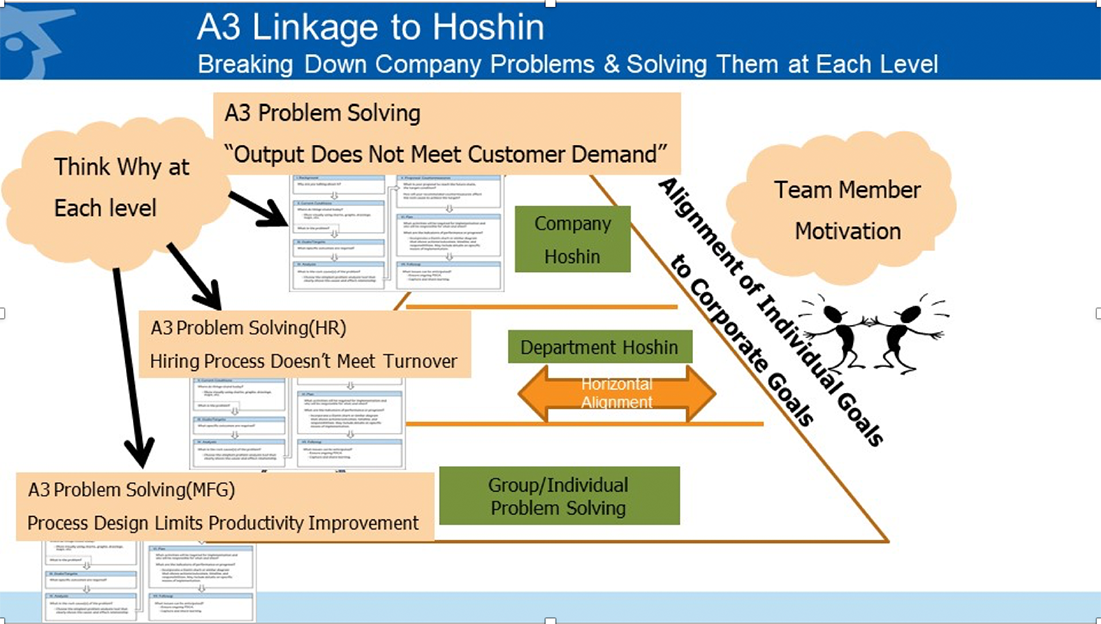

He shares the following graphic to illustrate this basic thinking:

The power of linking HK and A3 thinking manifests when the problem-solving method is properly framed as a way of prioritizing and allocating resources at the corporate level in alignment with parts of the organization such as engineering, human resources, finance, and other departments. Grounding the problem-solving work in tangible work at the frontlines ensures that the right problems are being tackled, and, he claims, creates an “opportunity to innovate new ways of operating throughout the business.”

Hoshin Kanri and A3 Problem-solving Are Symbiotic

He closes his article with a powerful insight about HK’s ability to create a natural line of sight for people between their current problems and broader purpose. “Ultimately, hoshin and A3 problem-solving are symbiotic. Like our skeleton and muscle, one does not work as effectively without the other. Hoshin kanri is needed to define and gain alignment on critical strategies across the organization, while A3 is used to solve the problems discovered in executing those strategies.”

Hoshin kanri does not exist as something isolated and abstract. Indeed, Mark illustrates this powerful dynamic in Pivoting Just-in-Time at Toyota, where he shares how HK enabled Toyota to pivot effectively in 2008-2009 when the financial system collapsed. He explains how Toyota turned to HK to help manage a period of unprecedented growth, during which it had to grapple with the Great Recession of 2008, a quality crisis in 2009, and the Sendai tsunami in 2011. The company tapped HK to build teamwork across headquarter functions, developed the capability of leaders to manage at a higher level, and broke down problems to the working level. An excellent synthesis of general reflections illustrated with personal evidence.

In closing I can find no better comment about HK establishing a clear line of sight between the work of someone at the front line and the broader goals of the organization, than John Shook’s closing statement in his article:

“Whatever we call it, hoshin kanri, like leadership, does not exist as something isolated and abstract. Like anything that is essential to lean, one must understand how it works from the very detailed, elemental levels of the work of the business. And like lean leadership, it is to be exercised at every level, every day, by everyone.”

Managing on Purpose with Hoshin Kanri

Learn how to develop strategy and build alignment.