Q: What are some of the signs that a company could benefit from a lean distribution strategy?

Graham: Some companies would look at it from the vantage point of an internal improvement initiative and cost savings. However, companies should also look at it in terms of their customer responsiveness, whether they have long or variable lead times, they’re not very flexible in delivery of their services, or have quality issues. These would be additional reasons to consider lean distribution as part of an overall supply chain strategy.

Q: How does the supply chain fit in?

Graham: If the group that manages inventory is aligned with the distribution operation and can reduce in-bound lead times and outbound finished-goods lead times, you can make substantial reductions in inventory.

Q: Are there “myths” that hold companies back from using a lean distribution model?

Graham: Yes, and the most common one is that lean is a manufacturing concept and doesn’t have any place in distribution. It goes something like this, “They have one-piece flow and assembly lines in manufacturing, but in distribution centers, we’ve got varying types of orders, and varying types of customers. All of that variation doesn’t lend itself to lean in the distribution operation.”

Q: How do you respond when you hear that?

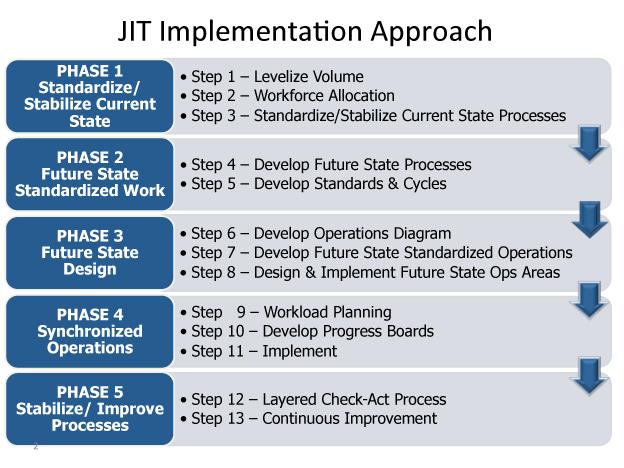

Graham: We explain that how we apply one-piece-flow in distribution is translating it down to small-lot processing. Typically what you are looking at is how small can we get that lot size, and then we put a standard and cycle to the batch of work, and—in conjunction with takt time of the customer—determine our staffing requirements.

Q: How do you begin implementing small-lot processing in a distribution center?

Graham: Developing a model within the warehouse first is always our suggested approach. Then we stabilize the model and expand the model to other functions in the operation. For outbound operations, we would typically recommend developing a model around an order type. Emergency, referral, and stock are typical order types. For inbound operations we would typically recommend developing a model around a mode of transportation—such as LTL, container, full trailer, or small parcel.

Q: Why is variation of orders so entrenched in traditional distribution?

Graham: Some of that variation is due to the policies of the organization, and this is why lean distribution is part of an overall supply chain strategy. Traditionally, companies give benefits for ordering a certain way. For example, if they want customers to order in large lots, they would give them economic-order quantity discounts; or they would allow them to return things when they place stock orders but not allow them to return things when they order on critical [express orders]. These policies try to regulate the behavior of the customers, resulting in true demand being held to gain benefits or created demand to gain benefits, and in turn variation in the volume passing through the distribution center.

Q: Ordering in large lots seems like such an entrenched practice. Why?

Graham: This is tied to the question on order variation. Often there are embedded supply chain policies that reward large-lot processing. Some of those policies have a financial component to them that need modification, such as transportation costs, returns, quantity discounts, sales promotions, etc., to encourage the behaviors consistent with the new way of doing business.

Providing evidence that these changes are worthwhile to all the stakeholders is key to enable these changes. We have found that we are most effective when the evidence is gained through the model with open communication and involvement. Another component is making your organizational resources available to assist your customers and suppliers successfully transition to the new ways.

Q: You mentioned a model a couple of times. How does that work?

Graham: This is a key challenge. First, we establish why it is important to change and what will be achieved competitively by moving to small batch; and what it provides to the customer, the supply chain and the distribution center. These are things like customer responsiveness at a lower cost, building a system to reveal problems, people continuously improving; sharing that knowledge developed through continuous improvement; and leaders developing the organization on these capabilities. It’s through the model that people are able to apply those capabilities and principles to develop and test methods and make them operational for their environment.

Q: How would you describe the big-picture goal of a lean distribution center/lean supply chain?

Graham: To create a cost-effective means throughout the system to receive orders and deliver products based on the pull of the customer with level and continuous flow. A company might have biweekly, bimonthly, and weekly orders coming in. If they can get that down to daily ordering—and sometimes they can break daily down into multiple hours a day—they will start moving away from infrequent variable orders and closer to fulfilling customer demand effectively. This will spur changes as well. For instance, if the order-management methods previously were geared toward large-lot processes, the distribution center might discover it has equipment that is oversized for a lean organization.

Q: Do labor costs go down as well?

Graham: We have found that in a traditional environment, the company typically over-allocates human resources anywhere from 12 to 30 percent because they operate at the shift level. Some operations hand out the work orders and say, “See you at the end of the shift,” and then at the end of the shift everyone clocks out and goes home. If there are problems that started early in the day, they usually don’t get addressed until later in the day, and then you are operating in a reactionary mode. In a lean environment, you manage minute-by-minute and hour-by-hour to make sure all of the operations are synchronized so that problems don’t cascade. When you manage in this way, you can allocate resources much more precisely. For example, you might find you can allocate two-and-a-half people to a process whereas in the past you might have allocated three or possibly four people. Additionally, those problems that are identified are used to drive continuous improvement activities in the operational area.

Q: Are there safety benefits as well?

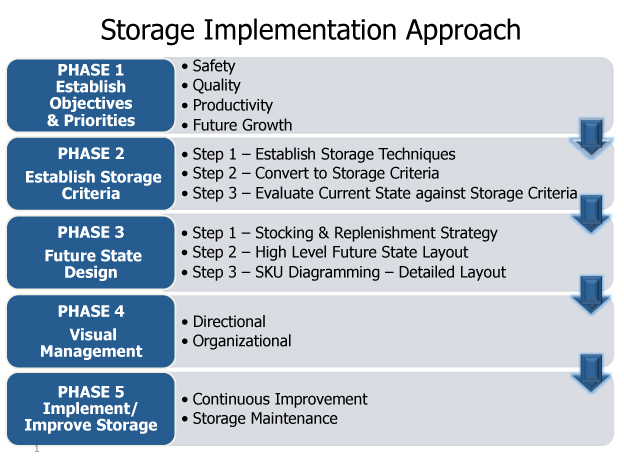

Graham: There are many. One of the key ones relates to storage and how you segregate materials and align those with inventory requirements. You can save space and build a safer environment for the person putting the stock away or picking the stock. Employees can be exposed to a lot of ergonomic injuries in the workplace, and having a purposeful storage plan can minimize risk of those injuries.

In fact, storage becomes a key enabler of the standard work cycle. In a traditional distribution setting, storage is one of those things that you do when you have time to get to it, so storage starts to deteriorate. In a lean distribution environment, you have a Plan for Every Part, and it’s the storage environment that facilitates stable standards and cycles that enable just-in-time delivery with quality and a safe working environment.

Q: What other lean tools does a lean distribution operation use in addition to a Plan for Every Part?

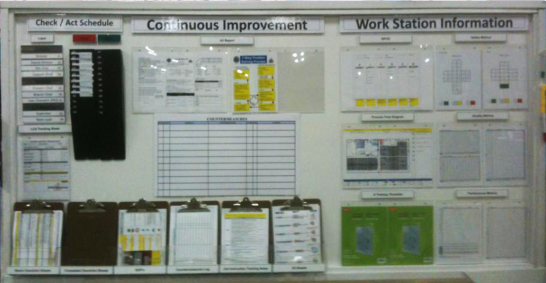

Graham: Usually there are progress boards [also called an hour-by-hour board] that are used for tracking progress on every shift to ensure the operation is moving in the right direction to service the orders and act as a source for opportunities to improve the operation. We obviously apply 5S and other visual management tools that help to identify whether processes and SOPs being adhered to. These could include layered check-act boards, value stream mapping, SIPOC+M diagrams and process-flow diagrams, and SOPs. Most importantly is a continuous improvement method that is applied by associates for continuous improvement activities. In the end, all of these tools help us to design processes that have defined, simple, direct flow with clear and binary connections between functions with standards so that we can see opportunities and solve problems to improve daily.

In a lean warehouse, visual management tools help to identify if teams are staying on standard. Here are three examples:

Q: How do customers benefit from lean distribution?

Graham: The company is able to provide a better quality product and service; and be much more responsive because when there are changes in the marketplace, they are able to change their processes more quickly to align with the marketplace changes. Not only is this good for customers, but it ensures that the company is able to reap the benefits of the changes. If a customer changes how it orders, the company can respond and be immediately more productive instead of being reactionary, where the impact on the operation is more ambiguous, and they take a wait-and-see approach.

Continue your learning:

Improve customer service, costs, efficiency, quality, safety, and space utilization while developing a problem-solving environment for continuous improvement in your warehouse and distribution processes. Register today for the in-depth workshop Lean Warehousing and Distribution Operations.

This hands-on workshop uses a benchmarking visit to an operating distribution center, a highly interactive simulation, exercises, instruction, group discussions and exercises to show you the key steps for how to implement lean principles in a traditional distribution operation.

Lean Warehousing and Distribution Operations

Improve a distribution center's efficiency, quality, safety, and space utilization.

I am exploring more information on using lean in warehousing environment in India. Can you please help in any way?