Recently, I was asked for my opinion on a lean effort in a help desk. The local manager, sincerely devoted to lean thinking, was telling me about how she’d been asked to reduce the total cost per call.

“I get this stuff,” she said. “But how can I convince my manager?” This is a question I’m often asked by readers of Lead With Respect. The question I ask is: Do you really?

We stood side by side as she looked at her open plan, telling me they had analyzed the process, and realized their problem was triage – getting customers to chose the right value stream upfront, so that specialized counselors could support them in solving their problem.

As I listened, I tried to apply the same lessons I’d be taught watching Toyota sensei decades ago, which anyone can find here.

Go and See Firsthand

Rather than look at the entire open plan wondering how to improve unit cost, we moved in close to watch what happened in a few sample calls and see what specific difficulties sales agent were encountering.

Users Come First, Then Dealers, Lastly the Maker

In just a few cases, we observed that the first choice the agent made is to explain to the caller that they had come to the wrong desk because they had wrongly picked the automated choices that steer you to the right counselor. The seller was telling the user that they’d worked badly, and so the maker would not be able to deliver on their request. The underlying assumption is that quality can only be guaranteed if the user follows the company’s process. Hmm… haven’t we all lived through that as users?

Variety – the Agent’s Immediate Problem

Just as on production cells 20 years ago, the agent was faced with a simple (but hard) problem of variety. There are an infinity of customer problems, but the agent is trained to solve quickly a small number of ones. How is the sales agent trained to meet the needs of the customer and to change mental brackets from one case to another seamlessly?

Constant Kaizen That Reflects Safety, Environment, Product Quality, and “Fun to Drive”

Kaizen (continuous improvement) is about honing each person’s discernment to seek a + alpha factor, a special care for the customer, for the work, and for colleagues and partners. Lean techniques are about developing everyone’s engagement and judgment so that people make the right choices within the daily changes created by variety. This includes changing from one customer to the next, from one process to the next, and making changes to the way we work to take waste out, at workstation level.

Engineers should wash their hands three times a day

It’s a question of perspective. Managers still seek global process solutions to build backlog lists, put together a response from bland items on the list without identity, and somehow assemble a black Ford T efficiently. This is the dream of output, not of customer outcomes. Customer outcomes require getting your hands dirty in understanding that the process might be common at a philosophical level, but at a reality level, every instance means something different. Something specific to offer. And specific is where quality lives.

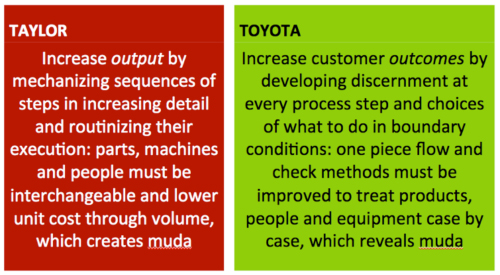

To explore this further, compare traditional “Taylorist” management (based on the thinking of Frederick Winslow Taylor) to modern, lean management (based on the leadership of Toyota):

To “get” Lean we have to change our specs, and no longer see processes as sequences of dependent tasks, but as sequences of dependent choices made on each one of these tasks. Just as we were taught by the sensei/coach. And if you weren’t taught by a truly knowledgeable sensei, you might think about finding one.